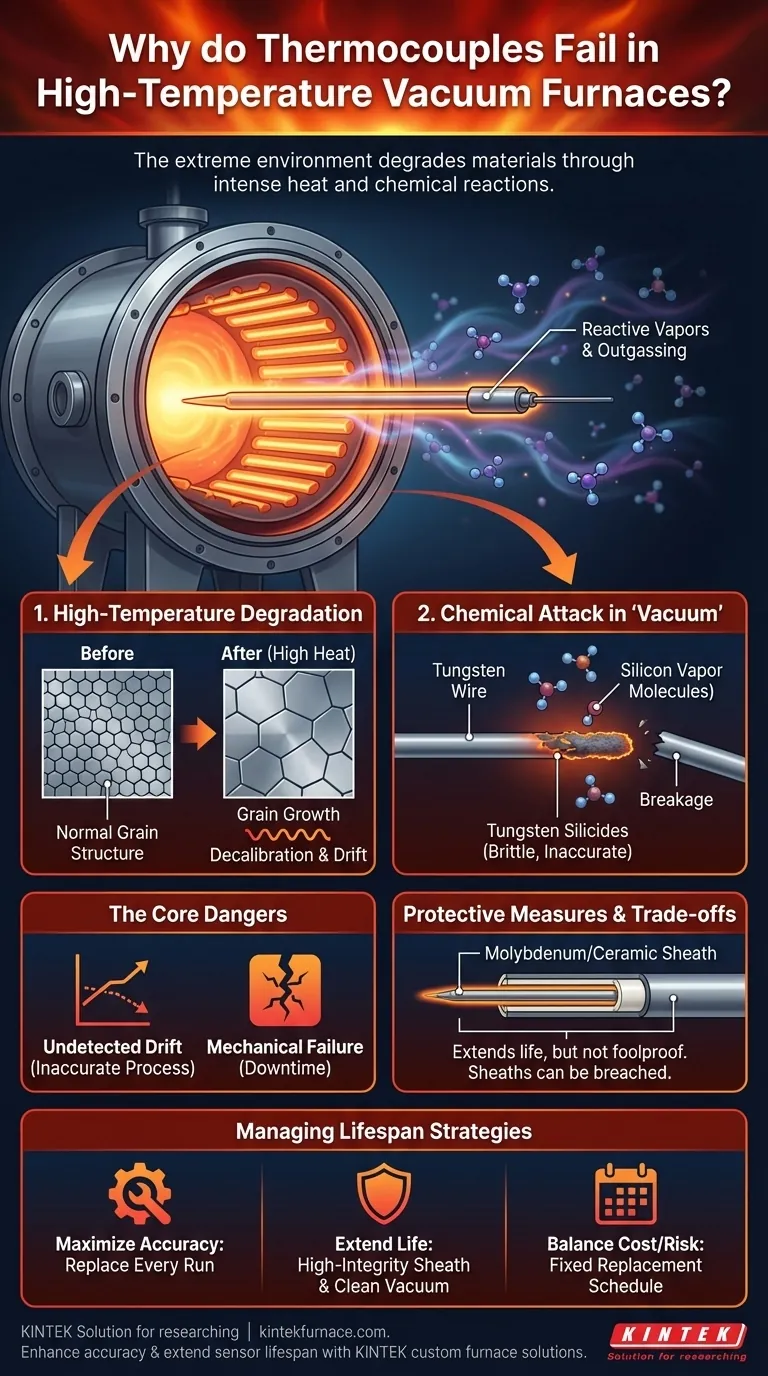

In short, thermocouples have a limited lifespan in high-temperature vacuum furnaces because the extreme environment itself degrades the sensor's materials. The combination of intense heat and chemical reactions with residual vapors in the vacuum causes the thermocouple's metal wires to change their physical and electrical properties, leading to inaccurate readings and eventual mechanical failure.

The core issue is that a vacuum furnace is not an empty, inert space. At extreme temperatures, the "vacuum" contains a low-pressure, chemically reactive atmosphere created by outgassing from the furnace components and the workpiece itself, which actively attacks the thermocouple.

The Core Mechanisms of Thermocouple Failure

To manage sensor lifespan, you must first understand the distinct forces working against it inside the furnace. Failure is rarely due to a single cause but rather a combination of thermal and chemical degradation.

High-Temperature Degradation

Even in a perfect, inert environment, extreme heat is the primary enemy. High temperatures cause the grain structure of the thermocouple's metal wires to grow and change.

This process, known as grain growth, alters the thermoelectric voltage characteristics of the metal. The result is a sensor that is no longer accurate, a phenomenon called decalibration or drift. The sensor may still provide a reading, but it will be wrong.

The Role of the "Vacuum"

A common misconception is that a vacuum is empty. In reality, it's a very low-pressure environment containing molecules that have outgassed from the furnace insulation, heating elements, and the product being processed.

At high temperatures, this outgassing intensifies, creating a dynamic atmosphere of various elements. This atmosphere, while at low pressure, is hot enough to be highly reactive with the thermocouple materials.

Chemical Attack from Process Vapors

Many high-temperature processes, such as brazing or sintering, release volatile elements. These elements become vapors that directly attack the thermocouple.

For example, a process involving silicon-bearing materials will create a silicon atmosphere. Similarly, processes can release vapors of aluminum, chromium, or carbon, each of which can react with the thermocouple alloys.

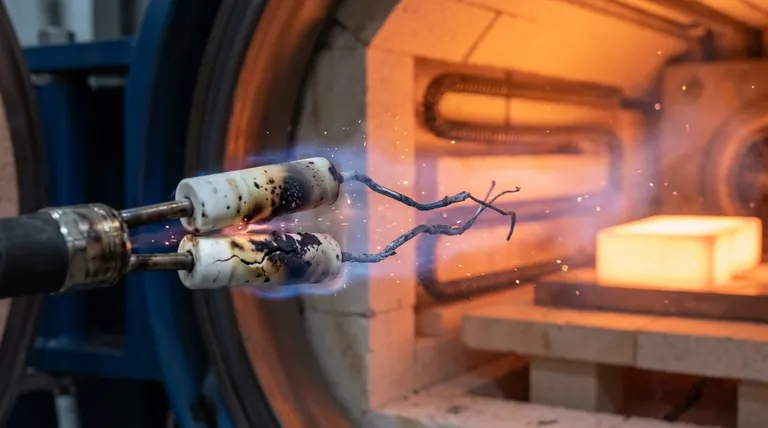

The Tungsten-Silicon Reaction

Tungsten-rhenium (Type C) thermocouples are often used in these furnaces because they can withstand temperatures up to 2320°C. However, they are highly susceptible to chemical attack.

As noted in furnace documentation, a silicon atmosphere is particularly destructive to tungsten. At high temperatures, silicon vapor reacts with the tungsten wires to form tungsten silicides. These new compounds are brittle and have completely different thermoelectric properties, causing rapid decalibration and breakage, often within just a few thermal cycles.

Understanding the Trade-offs

Using these sensitive instruments in such a harsh environment is a deliberate engineering compromise. The limitations are accepted because the alternatives are often non-existent or impractical for achieving the desired process temperatures.

Why Use Materials Prone to Failure?

We use materials like tungsten-rhenium because they are among the only options capable of measuring temperatures above the melting point of more common platinum-rhodium thermocouples (Types S, R, and B).

The short lifespan is the known price for obtaining temperature data in the 1600°C to 2300°C range. The choice is not between a long-life sensor and a short-life sensor, but between a short-life sensor and no sensor at all.

The Danger of Sensor Drift

Outright failure, where the thermocouple breaks, is obvious. A more dangerous problem is undetected drift.

As the thermocouple degrades chemically, its readings become progressively less accurate. If this isn't caught, your process will run at the wrong temperature, potentially leading to millions of dollars in scrapped product. This is why understanding the expected lifespan is critical for process control.

Protective Sheaths Are Not a Perfect Solution

Thermocouples are often protected by a sheath made of molybdenum, tantalum, or a ceramic like alumina. While these sheaths provide a barrier, they are not foolproof.

At extreme temperatures, the sheaths themselves can become porous or react with the process atmosphere. Once breached, the reactive vapors will quickly destroy the thermocouple inside. The sheath extends life but does not grant immunity.

How to Apply This to Your Process

Your strategy for managing thermocouple lifespan should align directly with your operational priorities.

- If your primary focus is maximum accuracy and process repeatability: Use a new thermocouple for every critical high-temperature run and consider it a consumable part of the process.

- If your primary focus is extending sensor lifespan: Use a high-integrity protective sheath (e.g., molybdenum or tantalum), ensure you are pulling a clean, deep vacuum to minimize residual gases, and avoid direct line-of-sight between the thermocouple and materials known to outgas aggressively.

- If your primary focus is balancing cost and risk: Establish a fixed replacement schedule based on your specific process data, replacing thermocouples after a set number of cycles or hours, regardless of whether they have failed.

By understanding these failure mechanisms, you can move from reacting to sensor failures to proactively managing them for more reliable and consistent furnace operations.

Summary Table:

| Cause of Failure | Effect on Thermocouple | Prevention/Mitigation |

|---|---|---|

| High-temperature grain growth | Decalibration and drift in readings | Use high-temperature alloys like tungsten-rhenium |

| Chemical attack from outgassed vapors (e.g., silicon) | Formation of brittle compounds, breakage | Employ protective sheaths (e.g., molybdenum, alumina) |

| Vacuum environment with reactive elements | Accelerated degradation and inaccuracy | Ensure deep vacuum and avoid aggressive outgassing sources |

Struggling with thermocouple failures in your high-temperature processes? KINTEK specializes in advanced furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to precisely meet your lab's unique needs, enhancing accuracy and extending sensor lifespan. Contact us today to optimize your furnace operations and reduce downtime!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability