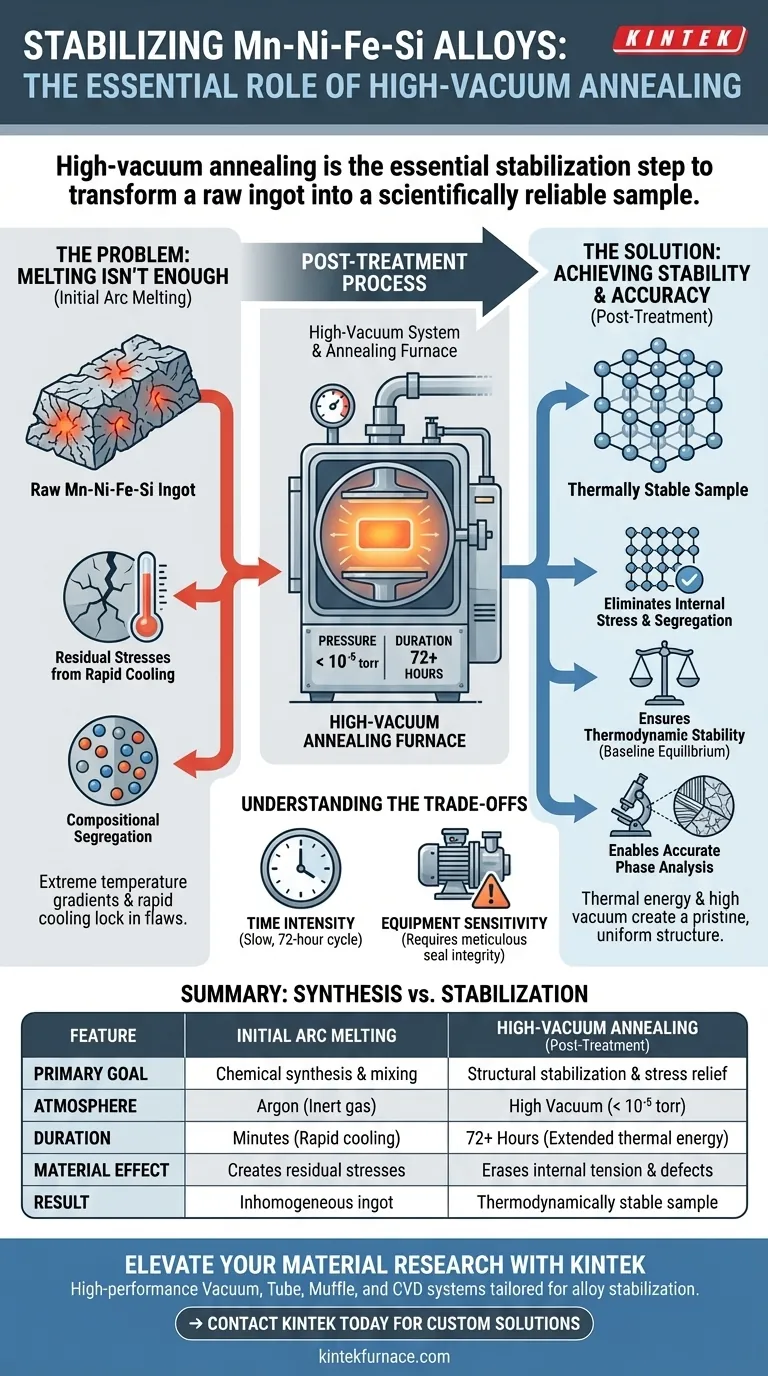

High-vacuum annealing is the essential stabilization step required to transform a raw Mn–Ni–Fe–Si alloy ingot into a scientifically reliable sample. By maintaining a pressure below 10⁻⁵ torr for extended periods (e.g., 72 hours), this system eliminates the microscopic defects and internal tensions created during the initial melting process, allowing the material to reach a state of thermodynamic equilibrium.

Core Takeaway: While initial arc melting defines the alloy's chemical makeup, high-vacuum annealing defines its structural integrity. It functions as a "reset button" that erases residual stresses and segregation, ensuring that any phase transformations observed later are inherent to the material properties, not artifacts of the manufacturing process.

The Problem: Why Melting Isn't Enough

To understand the necessity of post-treatment, one must first recognize the limitations of the initial synthesis.

Residual Stresses from Rapid Cooling

The initial creation of the alloy involves arc melting under an argon atmosphere. While effective for combining raw materials, this process involves extreme temperature gradients.

As the alloy cools rapidly from these high temperatures, significant residual stresses are locked into the crystal lattice. These stresses can warp the material's behavior during future testing.

Compositional Segregation

Despite mechanical flipping and repeated remelting to encourage mixing, the solidification process is rarely perfect at the microscopic level.

Compositional segregation occurs when elements do not distribute perfectly evenly as the liquid turns to solid. Without correction, this results in a chemically inhomogeneous sample that yields inconsistent data.

The Solution: The Role of High-Vacuum Annealing

The annealing furnace addresses the deep structural issues left behind by the melting process.

Eliminating Internal Stress

Subjecting the alloy to high temperatures for a long duration (e.g., 72 hours) provides the thermal energy required for atomic diffusion.

This allows the atoms to rearrange themselves, effectively eliminating residual stresses. The material "relaxes" into a uniform structure.

Ensuring Thermodynamic Stability

The goal of this treatment is to bring the alloy to a thermodynamically stable state.

By erasing the chaotic history of the initial melt, the alloy achieves a baseline equilibrium. This is the only state in which reliable scientific measurements can be taken.

Enabling Accurate Phase Analysis

The ultimate purpose of this stability is to facilitate accurate observation in subsequent analyses.

Specifically, it allows for the clear distinction of martensitic and austenitic phase transformations. If the alloy remained stressed, these delicate phase changes would be obscured or altered by internal tension.

Preventing Oxidation via High Vacuum

The specific requirement of a high-vacuum system (< 10⁻⁵ torr) is critical for purity.

While argon protects the alloy during the quick melting phase, long-term heat treatment requires a vacuum to prevent trace oxidation. This ensures the surface remains pristine for characterization.

Understanding the Trade-offs

While necessary for high-quality data, high-vacuum annealing presents specific challenges.

Time Intensity

The process is inherently slow. A 72-hour cycle creates a significant bottleneck in the material production workflow compared to the rapid speed of arc melting.

Equipment Sensitivity

Maintaining a vacuum below 10⁻⁵ torr requires sophisticated pumping systems and meticulous seal integrity. Any leak during the 72-hour window compromises the sample's purity through oxidation.

Making the Right Choice for Your Goal

To obtain valid data on Mn–Ni–Fe–Si alloys, you must differentiate between synthesis and stabilization.

- If your primary focus is initial chemical synthesis: Rely on the arc melting furnace with argon protection and mechanical flipping to ensure macroscopic homogeneity.

- If your primary focus is structural characterization: You must employ the high-vacuum annealing furnace to remove stress and segregation, ensuring the observed phase changes are genuine.

By strictly controlling the vacuum and temperature during post-treatment, you guarantee that your data reflects the true physics of the alloy, rather than the flaws of its creation.

Summary Table:

| Feature | Initial Arc Melting | High-Vacuum Annealing (Post-Treatment) |

|---|---|---|

| Primary Goal | Chemical synthesis & mixing | Structural stabilization & stress relief |

| Atmosphere | Argon (Inert gas) | High Vacuum (< 10⁻⁵ torr) |

| Duration | Minutes (Rapid cooling) | 72+ Hours (Extended thermal energy) |

| Material Effect | Creates residual stresses | Erases internal tension & defects |

| Result | Inhomogeneous ingot | Thermodynamically stable sample |

Elevate Your Material Research with KINTEK

Don't let manufacturing artifacts compromise your research. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Vacuum, Tube, Muffle, and CVD systems tailored for the rigorous demands of alloy stabilization and phase analysis.

Whether you need custom high-vacuum annealing furnaces or specialized lab high-temp systems, our solutions ensure your materials achieve the thermodynamic equilibrium required for accurate scientific breakthroughs.

Ready to optimize your heat treatment process?

→ Contact KINTEK Today to Discuss Your Custom Needs

Visual Guide

References

- Shantanu Kumar Panda, Manoranjan Kar. Effect of temperature and magnetic field induced hysteresis on reversibility of magnetocaloric effect and its minimization by optimizing the geometrical compatibility condition in Mn–Ni–Fe–Si alloy. DOI: 10.1063/5.0177061

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What densification mechanism does oscillatory pressure sintering introduce? Harness Shear Forces for h-BN Ceramics

- What temperature range is used in vacuum brazing? Achieve Strong, Flux-Free Metal Joints

- What is the significance of maintaining a vacuum environment during thermal evaporation? Achieve High Purity Thin Films

- How does vacuum annealing contribute to stress relief in materials? Achieve Clean, Stable Results for Your Lab

- What critical tasks does a vacuum drying oven perform for WPU films? Ensure Defect-Free Composite Material Integrity

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why must a vacuum system maintain a high vacuum during Al2O3-TiC sintering? Ensure Material Integrity & Density

- What are the benefits of using a vacuum environment in heat treatment? Achieve Superior Metallurgical Control