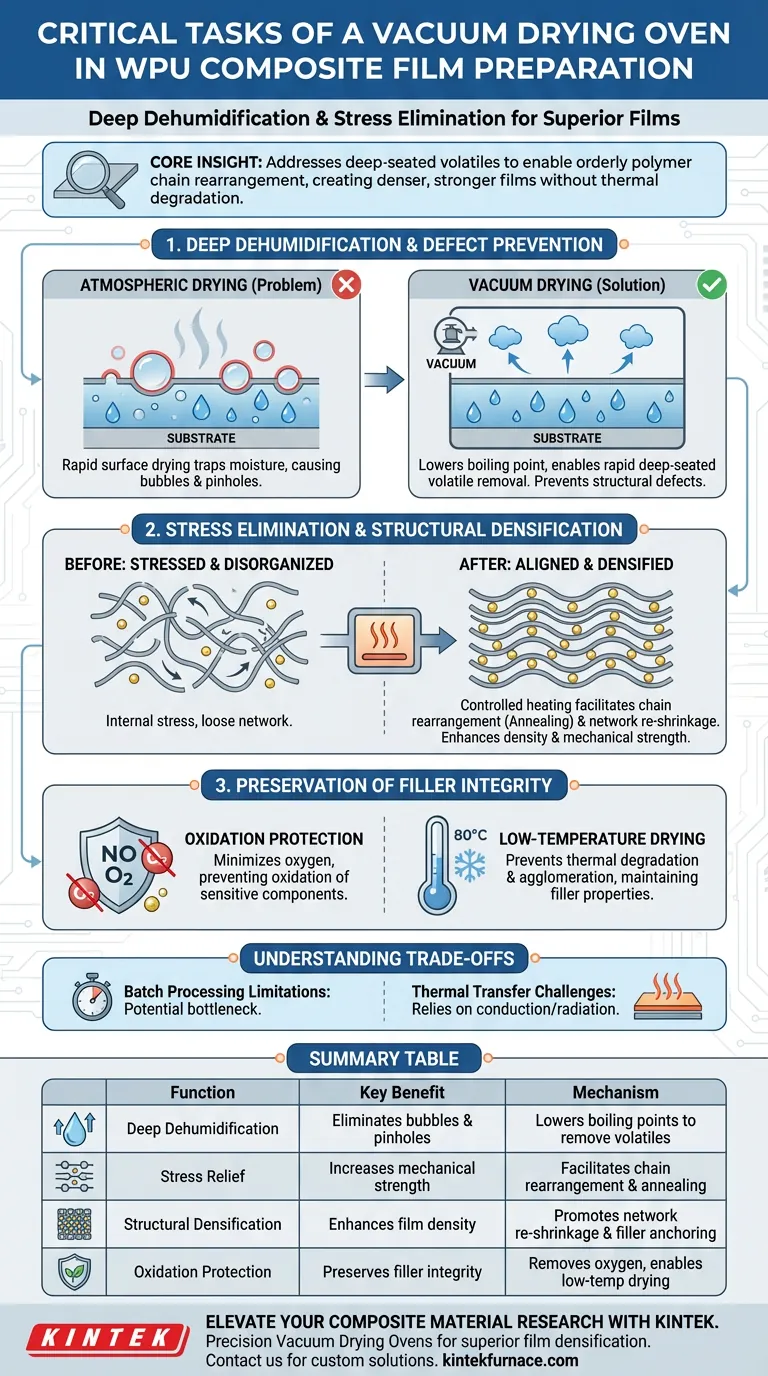

A vacuum drying oven is essential for deep dehumidification and the elimination of internal stress during the late stages of Waterborne Polyurethane (WPU) film formation. By creating a negative pressure environment combined with controlled heating, the oven accelerates the removal of residual water and trace solvents, effectively preventing the formation of structural defects like bubbles or pinholes.

Core Insight While standard drying removes surface moisture, vacuum drying addresses the deep-seated volatiles that compromise structural integrity. It enables the orderly rearrangement of polymer chains, resulting in a denser, mechanically stronger composite film without the risk of high-temperature thermal degradation.

Mechanisms of Film Stabilization

Accelerated Volatile Migration

The primary function of the vacuum oven is to remove volatiles that are trapped deep within the polymer matrix.

By lowering the environmental pressure, the oven reduces the boiling point of water and residual solvents.

This allows these fluids to migrate to the surface and evaporate rapidly, even at moderate temperatures (e.g., 80 °C), ensuring complete deep dehumidification.

Prevention of Structural Defects

During the formation of WPU films, trapped pockets of vapor can lead to catastrophic defects.

If drying occurs only at atmospheric pressure, rapid surface drying can trap moisture inside, leading to bubbles or pinholes.

The vacuum environment ensures that gas and vapor are continuously evacuated, preventing these voids from forming and ensuring a smooth, continuous film surface.

Enhancing Material Properties

Stress Elimination and Chain Rearrangement

Beyond simple drying, the vacuum oven acts as a critical annealing chamber.

The controlled heating environment facilitates the mobility of polymer chains.

This mobility allows the chains to undergo orderly rearrangement, which relieves internal stress accumulated during earlier processing stages.

Structural Densification

As the polymer chains rearrange and volatiles are evacuated, the material structure densifies.

The vacuum pressure promotes the re-shrinkage of the swollen polyurethane network.

This shrinkage helps securely anchor fillers—such as nanoparticles or quantum dots—within the polymer matrix, preventing them from leaching out and enhancing the overall mechanical strength of the composite.

Preservation of Filler Integrity

Composite films often contain sensitive fillers that can degrade under high heat or in the presence of oxygen.

The vacuum environment minimizes the presence of oxygen, protecting sensitive components (like metal nanoparticles or functional groups) from oxidation.

Furthermore, by enabling drying at lower temperatures, the process prevents the hard agglomeration of nanosheets, maintaining the specific surface area and chemical stability of the fillers.

Understanding the Trade-offs

Batch Processing Limitations

Unlike continuous conveyor-belt dryers, vacuum ovens generally operate as batch processes.

This can create a bottleneck in high-throughput manufacturing environments, as the chamber must be sealed, evacuated, and repressurized for every cycle.

Thermal Transfer Challenges

In a vacuum, there is no air to transfer heat via convection.

Heating relies primarily on conduction from the shelves or radiation.

This requires precise temperature control of the shelf surfaces to ensure the WPU film cures evenly without creating "hot spots" that could unevenly crosslink the polymer.

Making the Right Choice for Your Goal

To optimize your WPU composite film preparation, tailor your vacuum drying parameters to your specific material needs:

- If your primary focus is mechanical strength: Prioritize a longer drying cycle at moderate heat to maximize polymer chain rearrangement and internal stress relief.

- If your primary focus is preserving sensitive fillers: Utilize the vacuum's ability to lower boiling points to dry at the lowest possible temperature, preventing oxidation and thermal degradation.

- If your primary focus is defect reduction: Ensure a gradual ramp-up of the vacuum level to prevent sudden boiling of solvents, which can rupture the film surface before it sets.

Effective vacuum drying transforms a WPU film from a simple dried coating into a dense, stress-free, and structurally integrated engineering material.

Summary Table:

| Function | Key Benefit | Mechanism |

|---|---|---|

| Deep Dehumidification | Eliminates bubbles & pinholes | Lowers boiling points to remove deep-seated volatiles |

| Stress Relief | Increases mechanical strength | Facilitates polymer chain rearrangement and annealing |

| Structural Densification | Enhances film density | Promotes network re-shrinkage and secure filler anchoring |

| Oxidation Protection | Preserves filler integrity | Removes oxygen and enables drying at lower temperatures |

Elevate Your Composite Material Research with KINTEK

Precision is paramount when preparing high-performance Waterborne Polyurethane (WPU) films. KINTEK provides industry-leading laboratory solutions, including high-performance Vacuum Drying Ovens, Muffle furnaces, and CVD systems designed to meet your most rigorous material specifications.

Backed by expert R&D and world-class manufacturing, our systems ensure uniform heat transfer and precise pressure control to prevent structural defects and preserve the integrity of sensitive fillers. Whether you need a standard setup or a fully customizable system for unique research needs, KINTEK is your partner in material excellence.

Ready to achieve superior film densification? Contact us today to find your custom solution.

Visual Guide

References

- Wanchao Wu, Chuanqun Hu. Preparation and Flame-Retardant Properties of DMMP/Nano-Silica/WPU Composite Materials. DOI: 10.3390/polym17081052

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is a vacuum heat treatment furnace required for IN718-CuCrZr? Maximize Bimetallic Bond Strength

- What critical process environments does a vacuum annealing furnace provide? Optimize Sm2Fe17Cx Alloy Heat Treatment

- Why is a vacuum resistance furnace necessary for Ti-Zr-Nb alloy annealing? Ensure Purity & Uniformity

- What are the key steps in the operation of a vacuum chamber? Master the Process for Precision Control

- How are vacuum brazing challenges overcome in furnace design? Master Precision and Purity for Strong Joints

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What effect does increasing quenching gas pressure have? Optimize Heat Treatment with High-Pressure Gas Quenching

- What are the stages of the heat treatment process in drop-bottom quench furnaces? Achieve Superior Hardness and Strength