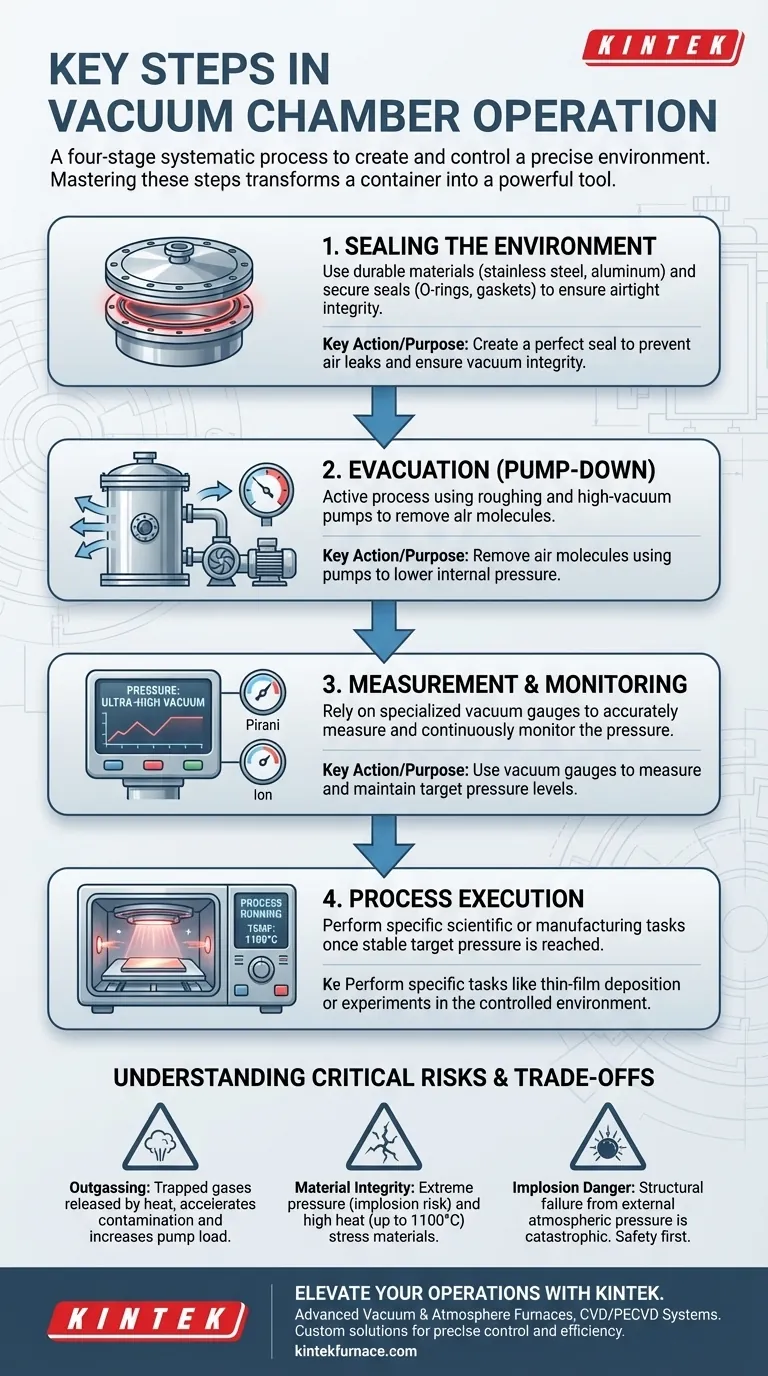

Fundamentally, operating a vacuum chamber is a four-stage process. It begins with creating a perfect seal, followed by using pumps to remove air and lower the internal pressure. This pressure is constantly monitored with gauges until a target level is reached, at which point the intended scientific or manufacturing process can be performed within the controlled environment.

The goal of operating a vacuum chamber is not simply to remove air, but to gain precise and stable control over an environment. Mastering this process requires understanding it as a system where the chamber, pumps, and gauges work together to create the necessary conditions for your specific application.

The Four Pillars of Vacuum Operation

Operating a vacuum system is a systematic process. Each stage builds upon the last, and a failure in one step will prevent success in the others.

Step 1: Sealing the Environment

Before any vacuum can be achieved, you must have a perfectly sealed chamber. This is the foundation of the entire operation.

The chamber itself must be constructed from durable, low-outgassing materials like stainless steel or aluminum. The integrity of its welds and surfaces is critical.

All entry points, such as doors and feedthroughs, rely on seals (like O-rings or copper gaskets) to prevent atmospheric air from leaking in. These must be clean, correctly sized, and free of any damage.

Step 2: Evacuation (The Pump-Down)

Evacuation is the active process of removing air molecules from the sealed chamber to lower the pressure.

This is accomplished with vacuum pumps. Often, a system uses a two-stage approach: a roughing pump removes the bulk of the air to reach a low vacuum, and then a high-vacuum pump (like a turbomolecular or diffusion pump) takes over to achieve much lower pressures.

The time it takes to pump down depends on the chamber volume, the pump's speed, and any leaks or outgassing present in the system.

Step 3: Measurement and Monitoring

You cannot see a vacuum, so you must rely on instruments to measure it accurately.

Vacuum gauges are specialized sensors that measure the pressure inside the chamber. Different types of gauges are required for different pressure ranges.

For example, a Pirani gauge is effective for measuring rough vacuum levels, while an ion gauge is necessary to measure high and ultra-high vacuum. Continuous monitoring confirms you have reached and are maintaining your target pressure.

Step 4: Process Execution

Once the vacuum environment is stable at the desired pressure, the actual work can begin.

This is the application-specific stage, which could be anything from a physics experiment or materials testing to an industrial process like thin-film deposition or electron-beam welding.

During this phase, you may also be controlling other variables like temperature or introducing specific process gases in a highly controlled manner.

Understanding the Critical Risks and Trade-offs

A vacuum chamber is not a simple container; it's an active system with inherent challenges, especially when performing advanced processes like high-temperature heating.

The Challenge of Outgassing

Outgassing is the release of trapped gases or vapors from the internal surfaces of the chamber and any items placed inside it. This process is accelerated by heat.

These released molecules add to the gas load, making it harder for the pumps to lower the pressure. Outgassing can also contaminate the process you are trying to run.

Material Integrity Under Stress

The force on a vacuum chamber is immense. A vacuum doesn't "suck"; rather, the external atmospheric pressure (about 14.7 pounds per square inch at sea level) pushes inward on every surface.

When adding extreme heat, as in a 1100°C process, materials must be chosen that can withstand both the pressure differential and the high temperature without deforming, degrading, or excessively outgassing. Materials like quartz, ceramics, and specific steel alloys are often required.

The Danger of Implosion

A structural failure in a vacuum chamber is not an explosion; it is an implosion. If a viewport, wall, or seal fails, the external atmospheric pressure will cause the chamber to collapse violently and catastrophically.

This is a significant safety hazard. Always ensure your chamber is rated for your intended vacuum level and that any modifications are professionally engineered and validated.

How to Apply This to Your Goal

Your operational focus will change depending on your specific objective.

- If your primary focus is basic experimentation: Prioritize achieving a stable vacuum by ensuring your chamber and seals are clean and leak-free.

- If your primary focus is high-purity manufacturing: Your main concern will be minimizing contamination by selecting low-outgassing materials and performing a "bake-out" to drive off volatile molecules before your process begins.

- If your primary focus is a high-temperature process: Safety and material integrity are paramount; you must verify that every component of your chamber can withstand the combined stress of vacuum and extreme heat.

Mastering these operational steps transforms a simple box into a powerful tool for manipulating the physical environment.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Sealing the Environment | Create a perfect seal to prevent air leaks and ensure vacuum integrity. |

| 2 | Evacuation (Pump-Down) | Remove air molecules using pumps to lower internal pressure. |

| 3 | Measurement and Monitoring | Use vacuum gauges to measure and maintain target pressure levels. |

| 4 | Process Execution | Perform specific tasks like thin-film deposition or experiments in the controlled environment. |

Ready to elevate your vacuum chamber operations? At KINTEK, we specialize in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring precise control, safety, and efficiency for your lab. Contact us today to discuss how our tailored solutions can optimize your processes and deliver superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion