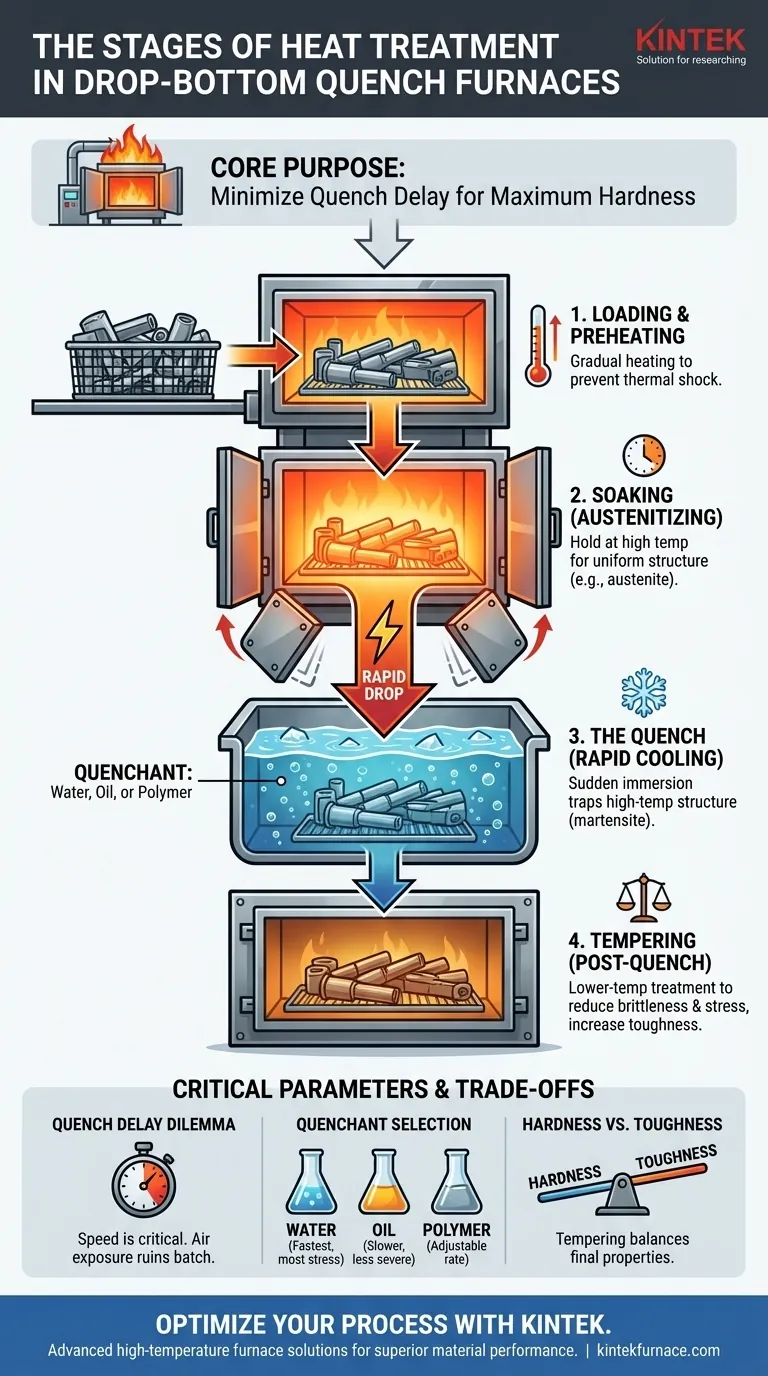

The drop-bottom furnace heat treatment process is a precise, multi-stage operation designed to impart specific mechanical properties to metal components. The core stages are preheating the material to a target temperature, soaking it to ensure uniformity, rapidly cooling it in a quench tank located directly below the furnace, and often a final tempering stage to refine its properties.

The primary advantage and entire purpose of a drop-bottom quench furnace is to minimize the time between the high-heat soaking stage and the rapid cooling stage. This extreme speed is critical for achieving the highest possible hardness and strength in certain alloys, particularly aluminum and steel.

The Purpose of Drop-Bottom Quench Furnaces

A drop-bottom furnace, also known as a solution quench furnace, is engineered for one specific task: delivering a heated part into a quenching medium with maximum speed and minimum heat loss.

This speed is known as minimizing quench delay. A delay of even a few seconds can allow the material's internal crystalline structure to begin changing in undesirable ways, compromising the final properties of the part.

A Stage-by-Stage Breakdown of the Process

Each stage serves a distinct metallurgical purpose, building upon the last to transform the material's microstructure.

Stage 1: Loading and Preheating

Parts are first loaded into a basket or onto a rack. This load is then raised into the furnace chamber.

The preheating cycle begins, bringing the material up to its target temperature in a controlled manner. This gradual heating prevents thermal shock, which can cause warping or cracking, especially in complex geometries.

Stage 2: Soaking (Austenitizing)

Once at the target temperature, the material enters the soaking stage. For steels, this is more accurately called austenitizing.

The material is held at this constant, high temperature for a calculated period. The goal is to allow the heat to penetrate the entire part, from surface to core, ensuring a complete and uniform change in its crystalline structure (e.g., forming austenite in steel).

Stage 3: The Quench (Rapid Cooling)

This is the defining stage of the process. The bottom doors of the furnace rapidly swing open, and the entire load is dropped or lowered into the quench tank situated directly beneath.

This sudden immersion in a liquid—typically water, oil, or a polymer—cools the material at an extremely high rate. This rapid cooling "traps" the high-temperature crystal structure, transforming it into a new, very hard structure (like martensite in steel).

Stage 4: Tempering (Post-Quench Treatment)

While the quenched part is extremely hard, it is also often very brittle and contains high levels of internal stress.

To counteract this, the part is often subjected to a final, lower-temperature heat treatment called tempering. This process reduces brittleness, increases toughness, and relieves the stresses created during the quench, making the part durable enough for its intended service.

Understanding the Trade-offs and Critical Parameters

Achieving consistent results requires understanding the inherent challenges and key variables of the process.

The Quench Delay Dilemma

The primary benefit—speed—is also the primary operational risk. Any failure in the door mechanism or lowering system that increases the time the hot part is exposed to air before quenching can ruin the entire batch.

Quenchant Selection

The choice of liquid in the tank is a critical decision. Water provides the fastest quench but creates the most thermal stress and distortion. Oils are slower and less severe, while polymers offer a cooling rate that can be adjusted between that of water and oil.

The Hardness vs. Toughness Balance

The tempering stage is a balancing act. More tempering increases toughness but slightly reduces the peak hardness achieved during the quench. The final properties must be carefully specified based on the component's application.

Applying This to Your Process Control

Use these principles to fine-tune your heat treatment goals.

- If your primary focus is maximum hardness: Ensure the austenitizing temperature and time are sufficient for a full transformation, and verify the quench delay is as close to zero as possible.

- If your primary focus is achieving specific, balanced properties: Pay close attention to the tempering temperature and time, as this stage offers the most control over the final trade-off between hardness and toughness.

- If your primary focus is minimizing distortion: Control the initial preheat ramp rate, ensure parts are loaded to allow for uniform quenchant flow, and select the least severe quenchant that can still achieve the required metallurgical properties.

Ultimately, mastering this process is about precisely manipulating a material's internal structure to achieve a predictable and reliable outcome.

Summary Table:

| Stage | Purpose | Key Details |

|---|---|---|

| Loading and Preheating | Prevent thermal shock | Gradual heating to target temperature |

| Soaking (Austenitizing) | Ensure uniform structure | Hold at high temperature for complete transformation |

| Quench (Rapid Cooling) | Achieve high hardness | Drop into quench tank (water, oil, polymer) to form martensite |

| Tempering | Reduce brittleness and stress | Lower-temperature treatment to balance hardness and toughness |

Ready to optimize your heat treatment process with precision and speed?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're aiming for maximum hardness, balanced properties, or minimized distortion in metals like aluminum and steel, our drop-bottom quench furnaces deliver rapid quenching with minimal delay to enhance your lab's efficiency and results.

Contact us today to discuss how we can help you achieve superior material performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production