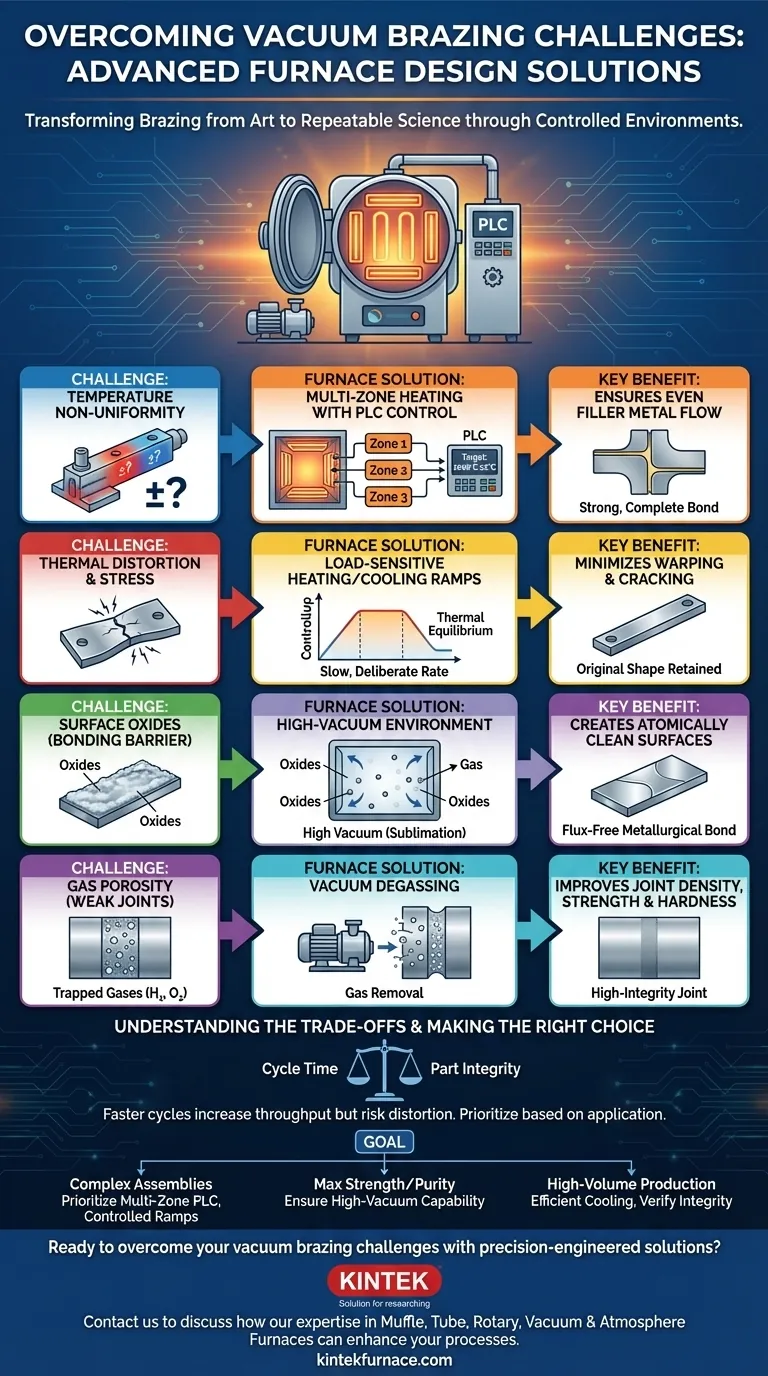

At its core, a vacuum brazing furnace overcomes process challenges not just by getting hot, but by creating a meticulously controlled environment. Key design features include multi-zone heating for precise temperature uniformity (±5°C), programmable controllers for load-sensitive heating rates that prevent thermal distortion, and a high-purity vacuum chamber that cleans metal surfaces at an atomic level, ensuring strong, flux-free joints.

The central purpose of a modern vacuum furnace is to transform brazing from a complex art into a repeatable science. It achieves this by actively managing the thermal and chemical conditions necessary to produce a perfect metallurgical bond, every time.

The Challenge of Temperature Uniformity

Perfect brazing depends on the filler metal melting and flowing evenly throughout the entire joint via capillary action. Non-uniform temperatures are the primary obstacle to achieving this.

Why Uniformity is Critical for Brazing Flow

If one part of the assembly is slightly colder, the filler metal may solidify prematurely, creating voids and an incomplete bond. If another part is too hot, it can damage the base metals or cause the filler alloy to erode the parent material.

Furnace Solution: Multi-Zone Heating & PLCs

To counteract this, furnaces are designed with multiple, independent heating zones. Each zone has its own thermocouple and is managed by a Programmable Logic Controller (PLC). This system constantly measures and adjusts power to different elements, ensuring the entire workload remains within a tight temperature window, often as precise as ±5°C.

Preventing Thermal Distortion and Stress

Heating a complex metal assembly will inevitably cause it to expand. The challenge is ensuring it expands and contracts evenly to avoid warping or cracking.

The Root Cause: Uneven Expansion

Thin-walled sections of a component heat up much faster than thick, massive sections. This differential expansion creates internal stresses that can permanently distort the part, compromising its final dimensions and integrity.

Furnace Solution: Load-Sensitive Heating Control

Modern furnace controls allow for carefully programmed heating ramps. By analyzing the mass and geometry of the load, operators can set slow, deliberate heating and cooling rates. This "load-sensitive" approach gives the entire assembly time to reach thermal equilibrium, minimizing the temperature differences that cause stress.

Achieving Atomically Clean Surfaces Without Flux

Traditional brazing relies on chemical fluxes to remove the oxide layer present on all metals. These fluxes can leave behind corrosive residues, but a vacuum furnace makes them unnecessary.

The Problem with Oxides

Even a seemingly clean metal surface is covered in a microscopic layer of oxides. This layer acts as a barrier, preventing the molten braze alloy from "wetting" the parent material and forming a strong metallurgical bond.

Furnace Solution: High-Vacuum Environments

The combination of high heat and low pressure inside a vacuum furnace creates an environment where many metal oxides become unstable. They break down and sublimate (turn from a solid directly to a gas), where they are then removed by the vacuum pump. This leaves behind an atomically pure metal surface, ideal for brazing.

The Degassing Benefit

The vacuum also serves to pull dissolved gases, like hydrogen and oxygen, out of the base metals themselves. Removing these trapped gases prevents porosity in the final joint, significantly improving its density, strength, and overall hardness.

Understanding the Trade-offs

While vacuum furnace technology is advanced, its application involves balancing competing priorities.

Cycle Time vs. Part Integrity

Faster heating and cooling cycles increase throughput and operational efficiency. However, aggressive temperature ramps also increase the risk of thermal distortion, especially with complex or thin-walled components. The primary trade-off is between production speed and the quality of the finished part.

Material Compatibility

Vacuum brazing is not suitable for all materials. Metals with a high vapor pressure, such as zinc, lead, or cadmium, can outgas at brazing temperatures. This process, known as "vaporization," can contaminate the furnace interior and, more importantly, alter the composition of the braze alloy, leading to poor joint quality.

Brazing vs. Sintering Design Priorities

Furnaces for different thermal processes have different designs. A vacuum sintering furnace, for example, may be designed for much higher temperatures (up to 2200°C) and feature rapid quenching systems to achieve a specific microstructure. A brazing furnace, by contrast, prioritizes absolute temperature uniformity and controlled ramps around the filler metal’s specific melting point.

Making the Right Choice for Your Goal

The ideal furnace design depends entirely on your specific application and primary objective.

- If your primary focus is complex, high-value assemblies: Prioritize furnaces with advanced, multi-zone PLC controls and fully programmable heating and cooling ramps to eliminate the risk of thermal distortion.

- If your primary focus is maximum joint strength and purity: Ensure the furnace's vacuum system can achieve the low pressures required to fully dissociate oxides from your specific base metals.

- If your primary focus is high-volume production: Seek designs with efficient cooling systems to shorten cycle times, but verify through testing that these faster cycles do not compromise the integrity of your parts.

Ultimately, selecting the right furnace design is about precisely controlling the physics of the process to deliver consistently perfect results.

Summary Table:

| Challenge | Furnace Solution | Key Benefit |

|---|---|---|

| Temperature Non-Uniformity | Multi-Zone Heating with PLC Control | Ensures even filler metal flow, preventing voids and incomplete bonds |

| Thermal Distortion | Load-Sensitive Heating and Cooling Ramps | Minimizes warping and cracking by managing differential expansion |

| Surface Oxides | High-Vacuum Environment for Oxide Sublimation | Creates atomically clean surfaces for strong, flux-free metallurgical bonds |

| Gas Porosity | Vacuum Degassing | Removes trapped gases to improve joint density, strength, and hardness |

Ready to overcome your vacuum brazing challenges with precision-engineered solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces tailored for diverse laboratory needs. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can enhance your brazing processes and deliver consistent, high-quality results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling