A vacuum heat treatment furnace is a critical requirement for the post-processing of IN718-CuCrZr bimetallic interfaces because it enables necessary high-temperature structural changes without compromising the material's integrity.

It specifically addresses the extreme oxygen sensitivity of the CuCrZr alloy while simultaneously providing the thermal energy needed to relieve residual stresses and strengthen the atomic bond between the two distinct metals.

By creating an oxygen-free environment, this process transforms a physical interface into a robust metallurgical bond through precipitation strengthening and atomic diffusion, all while preventing the oxidation that would otherwise ruin the copper alloy.

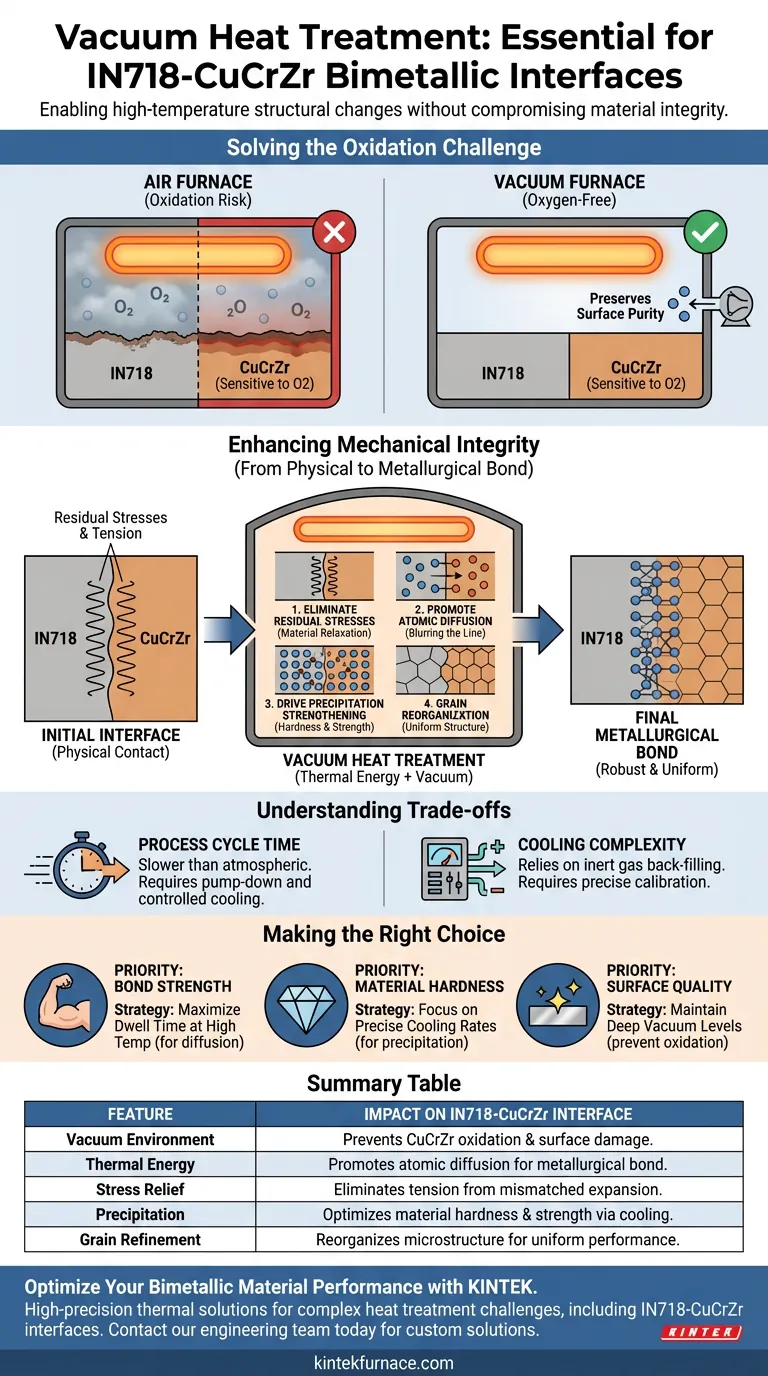

Solving the Oxidation Challenge

The Sensitivity of CuCrZr

The primary driver for using a vacuum environment is the chemical nature of the copper alloy (CuCrZr).

This alloy is extremely sensitive to oxygen at elevated temperatures. If treated in a standard air furnace, the copper components would suffer from severe oxidation damage, compromising the component's surface and structural integrity.

Preserving Surface Purity

A vacuum furnace eliminates oxygen from the heating chamber.

This ensures that while the material undergoes high-temperature processing to improve its internal structure, the exterior and the delicate interface remain free of oxides and impurities.

Enhancing Mechanical Integrity

Eliminating Residual Stresses

Joining two different materials like Inconel 718 (IN718) and CuCrZr creates significant internal tension due to mismatched thermal properties.

The high-temperature environment of the furnace allows the material to relax. This effectively eliminates residual stresses that could otherwise lead to warping or premature failure of the joint.

Promoting Elemental Diffusion

For a bimetallic interface to be strong, atoms from both metals must migrate across the boundary to create a solid metallurgical bond.

The furnace provides the thermal energy required to promote the diffusion of interfacial elements. This blurs the distinct line between the two metals, significantly enhancing the connection strength.

Driving Precipitation Strengthening

Both IN718 and CuCrZr rely on the formation of specific internal precipitates to achieve their target hardness and strength.

Through precise temperature holding and specific cooling rates (such as furnace cooling or gas cooling), the vacuum furnace induces precipitation strengthening. This process optimizes the hardness of both materials simultaneously.

Grain Reorganization

The microstructure of the metal often needs to be "reset" after the joining process.

Heat treatment enables grain reorganization, refining the crystalline structure of the alloys to ensure uniform mechanical properties throughout the component.

Understanding the Trade-offs

Process Cycle Time

Vacuum heat treatment is inherently slower than atmospheric processing.

The need to pump down the chamber to a high vacuum before heating, and the reliance on radiation or gas convection for cooling, can extend cycle times significantly compared to conventional methods.

Complexity of Cooling Control

Achieving specific cooling rates to "lock in" material properties is more complex in a vacuum.

Because there is no air to convey heat away naturally, the furnace must rely on sophisticated back-filling of inert gases to control the cooling rate, which requires precise equipment calibration.

Making the Right Choice for Your Goal

When configuring your post-processing strategy for IN718-CuCrZr interfaces, consider these priorities:

- If your primary focus is Bond Strength: Prioritize longer dwell times at high temperatures to maximize elemental diffusion across the interface.

- If your primary focus is Material Hardness: Focus on the cooling phase, ensuring your furnace can achieve the specific cooling rates required to trigger precipitation strengthening.

- If your primary focus is Surface Quality: Ensure your vacuum system is capable of maintaining deep vacuum levels throughout the entire cycle to prevent even trace oxidation of the CuCrZr.

Ultimately, the vacuum heat treatment furnace is not just a tool for heating; it is a precision instrument for engineering the atomic landscape of your bimetallic interface.

Summary Table:

| Feature | Impact on IN718-CuCrZr Bimetallic Interface |

|---|---|

| Vacuum Environment | Eliminates oxygen to prevent CuCrZr oxidation and surface damage. |

| Thermal Energy | Promotes atomic diffusion to transform physical contact into a metallurgical bond. |

| Stress Relief | Eliminates residual tension caused by mismatched thermal expansion. |

| Precipitation | Optimizes material hardness and strength through controlled cooling cycles. |

| Grain Refinement | Reorganizes microstructure for uniform mechanical performance. |

Optimize Your Bimetallic Material Performance with KINTEK

Ensure the integrity of your sensitive alloys with KINTEK’s high-precision thermal solutions. Backed by expert R&D and world-class manufacturing, we provide customizable Vacuum, Muffle, Tube, and CVD systems designed to solve your most complex heat treatment challenges.

Whether you are processing IN718-CuCrZr interfaces or advanced aerospace components, our systems offer the precise cooling control and deep vacuum levels required for high-performance bonding and precipitation strengthening.

Ready to upgrade your lab’s capabilities? Contact our engineering team today to discuss a custom furnace solution tailored to your unique research and production needs.

Visual Guide

References

- Hamidreza Javidrad, Bahattin Koç. Study of the Effect of Process Parameters and Heat Treatment on the Formation and Evolution of Directed Energy Deposition of IN718‐CuCrZr Interface. DOI: 10.1002/adem.202500773

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What is the purpose of vacuum sintering furnaces? Achieve High-Purity, Dense Materials

- What is the role of a high-temperature sintering furnace? Achieve Full Densification for Metal Components

- Why is a Spark Plasma Sintering (SPS) system superior to traditional furnaces? Speed and Density for Ceramics

- What is the function of a high-temperature sintering furnace in 4D printed ceramics? Transform Designs into Reality

- How are vacuum annealing furnaces used in solar cell manufacturing? Boost Efficiency with Precision Heat Treatment

- How does a vacuum annealing furnace work? Unlock Pristine Material Processing

- What types of materials are compatible with low vacuum versus high vacuum furnaces? Choose the Right Furnace for Your Materials