At its core, a vacuum annealing furnace is a specialized heat-treating chamber that first removes nearly all air and other gases before heating a material. This process is not about the heat treatment itself, but about creating a pristine, chemically non-reactive environment. By precisely controlling the temperature and atmosphere, the furnace modifies a material's internal microstructure to make it softer and more ductile, all without damaging or contaminating its surface.

The essential principle of a vacuum furnace is not the heating, but the vacuum. By creating an inert environment free from oxygen and other reactive gases, it prevents surface oxidation and decarburization, ensuring the material's properties are altered exactly as intended while preserving a bright, clean finish.

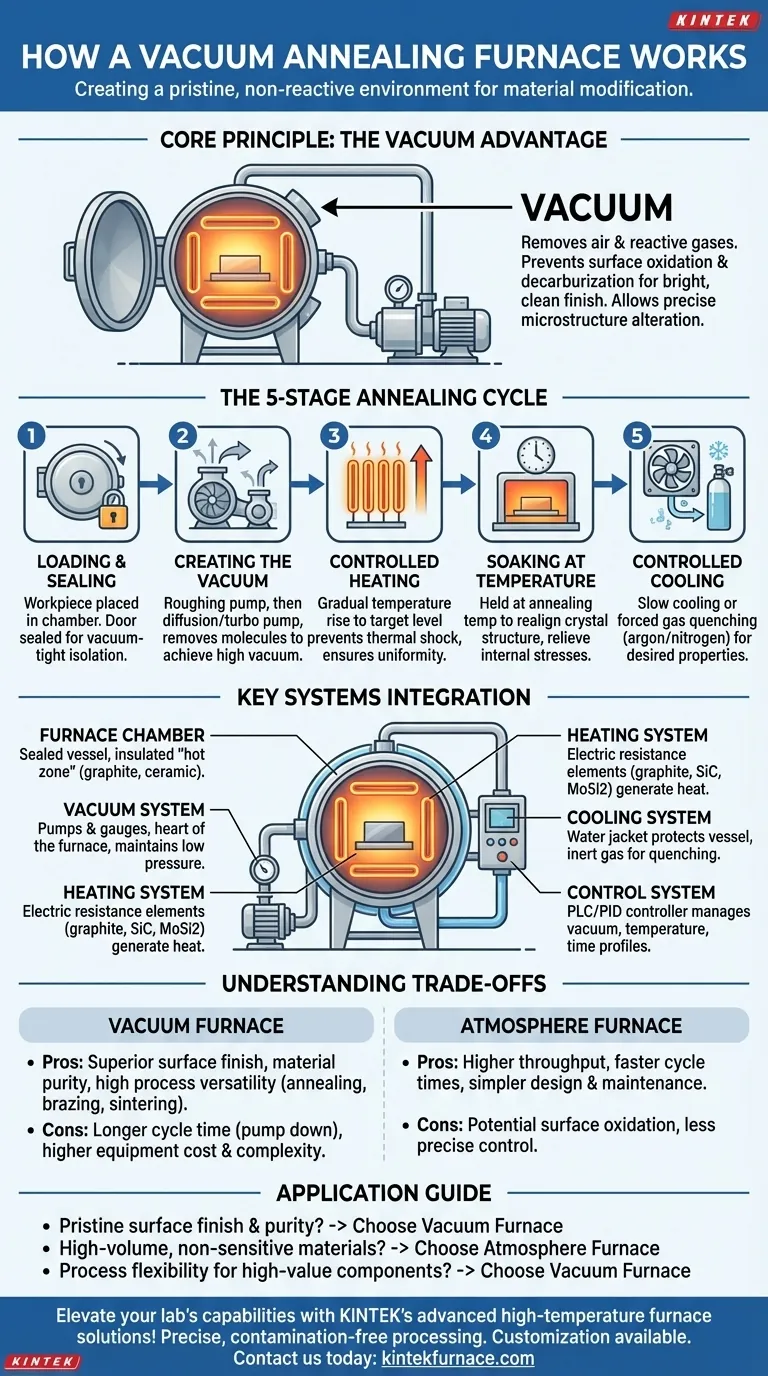

The Five Stages of the Vacuum Annealing Cycle

The operation of a vacuum annealing furnace is a precisely controlled, sequential process. Each stage serves a critical function in achieving the final desired material properties.

Stage 1: Loading and Sealing

The process begins by placing the workpiece or material inside the furnace chamber. The chamber door is then sealed to create a vacuum-tight enclosure, isolating the internal environment from the outside atmosphere.

Stage 2: Creating the Vacuum

The vacuum system activates. This is often a multi-step process where a mechanical "roughing" pump removes the bulk of the air. Then, a diffusion or turbomolecular pump takes over to achieve a high-level vacuum, removing the vast majority of remaining molecules.

Stage 3: Controlled Heating

Once the target vacuum level is reached, the heating system engages. Heating elements gradually raise the chamber temperature at a controlled rate. This slow, even heating prevents thermal shock and ensures the entire workpiece reaches the target temperature uniformly.

Stage 4: Soaking at Temperature

The furnace holds the material at the specified annealing temperature for a predetermined duration. This "soaking" period allows the material's internal crystal structure to realign, relieving internal stresses and increasing its ductility.

Stage 5: Controlled Cooling

After the soaking stage is complete, the heating elements are turned off. The material is cooled in a controlled manner, either by natural radiation within the vacuum, or more commonly, by introducing a high-purity inert gas like argon or nitrogen to accelerate the cooling rate in a process called forced gas quenching.

The Key Systems That Make It Work

A vacuum annealing furnace is an integrated system where several key components work in concert to manage the environment and thermal cycle.

The Furnace Chamber

This is the sealed vessel that contains the workpiece. It is often constructed with a "hot zone" made from materials like graphite, molybdenum, or ceramic fiber that can withstand extreme temperatures while remaining chemically stable.

The Vacuum System

This is the heart of the furnace. It consists of a series of pumps (mechanical, diffusion, molecular) and gauges that work together to evacuate the chamber and maintain the required low-pressure environment throughout the cycle.

The Heating System

Electric resistance elements are typically used to generate heat. These can be made of graphite, silicon carbide (SiC), or molybdenum disilicide (MoSi2), chosen based on the required operating temperature and chemical compatibility.

The Cooling System

This system manages heat dissipation. A water-cooling jacket on the exterior of the furnace chamber protects the vessel from overheating. For rapid cooling of the workpiece, an internal gas cooling system circulates inert gas over the material.

The Control System

Modern furnaces are automated using a Programmable Logic Controller (PLC) or PID controller. This system is the brain of the operation, precisely managing vacuum levels, heating rates, soak times, and cooling profiles to ensure repeatable and accurate results.

Understanding the Trade-offs

While vacuum furnaces offer superior results, it's important to understand their operational and economic trade-offs compared to conventional atmosphere furnaces.

Cycle Time vs. Process Purity

The time required to pump down the chamber to a deep vacuum adds to the overall cycle time. For applications where surface oxidation is not a concern, a traditional atmosphere furnace offers higher throughput.

Equipment Cost and Complexity

Vacuum furnaces are more complex and expensive to purchase and maintain. The high-performance vacuum pumps, seals, and advanced control systems represent a significant investment compared to simpler furnace designs.

Process Versatility as a Benefit

The highly controlled environment of a vacuum furnace makes it extremely versatile. The same piece of equipment can often be used for other thermal processes like vacuum brazing, sintering, and age hardening, providing more utility from a single capital investment.

How to Apply This to Your Goal

Your choice of furnace technology depends entirely on your material requirements and production goals.

- If your primary focus is a pristine surface finish and material purity: A vacuum furnace is the superior choice, as it is the only way to completely eliminate oxidation and surface contamination.

- If your primary focus is high-volume processing of non-sensitive materials: A conventional atmosphere furnace may be more economical due to its simpler design and faster cycle times.

- If your primary focus is process flexibility for high-value components: The ability of a vacuum furnace to perform multiple clean processes like annealing, brazing, and sintering in one unit offers significant value.

Ultimately, a vacuum annealing furnace provides unparalleled control over both the material's internal structure and its external surface.

Summary Table:

| Stage | Description |

|---|---|

| Loading and Sealing | Place workpiece in chamber and seal for vacuum-tight isolation. |

| Creating the Vacuum | Use pumps to remove air, achieving high vacuum levels. |

| Controlled Heating | Heat gradually to prevent thermal shock and ensure uniformity. |

| Soaking at Temperature | Hold at annealing temperature to realign microstructure and relieve stress. |

| Controlled Cooling | Cool via radiation or forced gas quenching for desired properties. |

Elevate your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise, contamination-free processing. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is enhanced by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can optimize your material annealing and other thermal processes for superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance