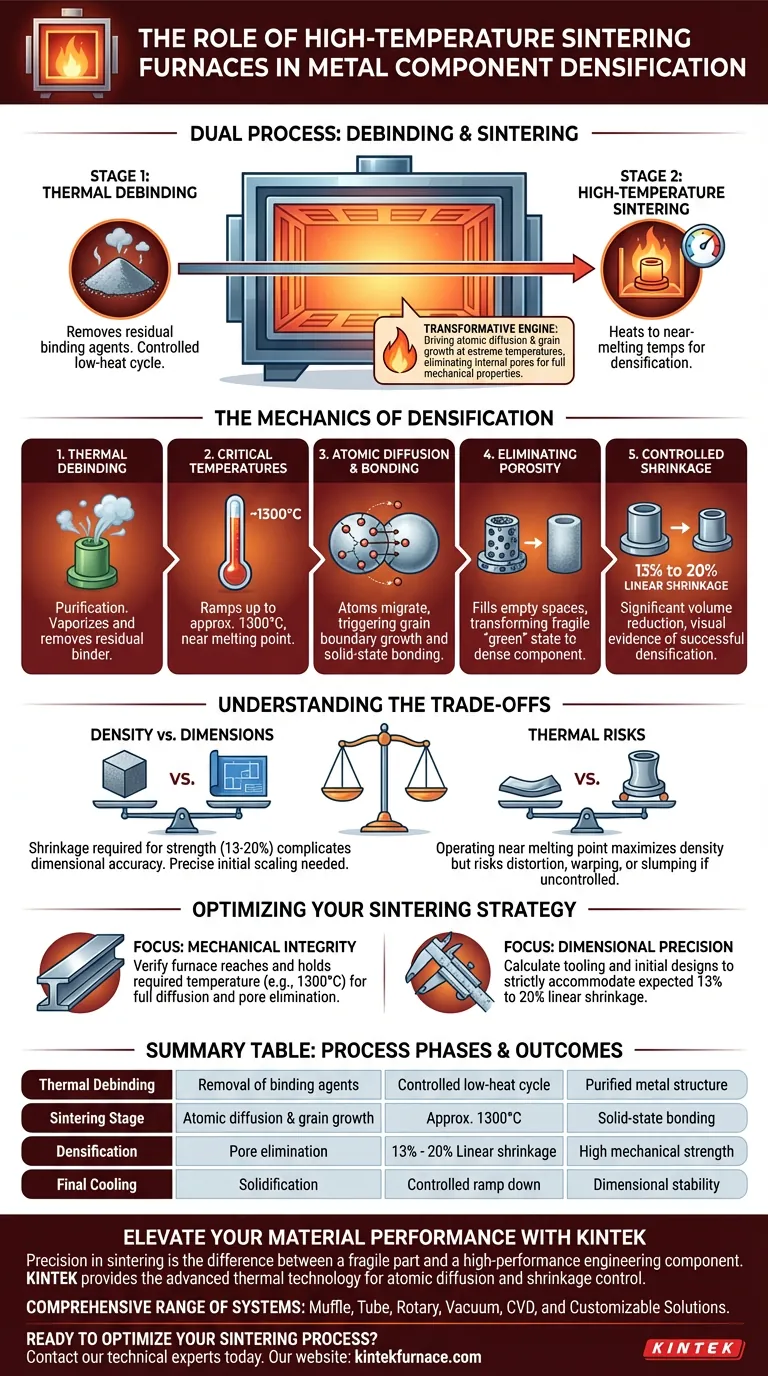

A high-temperature sintering furnace is the transformative engine responsible for converting loosely bound metal powder into a solid, high-performance component. It executes a dual process: first removing residual binding agents through thermal debinding, and subsequently heating the material to near-melting temperatures to fuse the particles into a dense, unified mass.

By driving atomic diffusion and grain growth at extreme temperatures, the sintering furnace forces the material to shrink by up to 20%, eliminating internal pores to establish the metal's full mechanical properties.

The Mechanics of Densification

Thermal Debinding

Before final densification can occur, the component must be purified. The furnace first initiates a thermal debinding cycle.

This stage applies controlled heat to vaporize and remove any residual binder materials that were previously used to hold the metal powder in its shape.

Reaching Critical Temperatures

Once the binder is removed, the furnace ramps the temperature up to extreme levels.

For many common alloys, temperatures are raised to approximately 1300°C. This specific heat level brings the metal particles close to their melting point without turning them into a liquid.

Atomic Diffusion and Bonding

At these elevated temperatures, the metal powder particles undergo a physical transformation.

The heat energy triggers diffusion, causing atoms to migrate across the boundaries of adjacent particles. This movement facilitates grain boundary growth, effectively welding the individual particles together at an atomic level.

Eliminating Porosity

As diffusion occurs, the empty spaces (pores) between the original powder particles are filled in.

The elimination of these pores is what transforms the part from a fragile "green" state into a dense metal component capable of withstanding structural loads.

Controlled Shrinkage

The removal of pore space results in a significant reduction in the component's physical volume.

Operators can expect a linear shrinkage of 13% to 20% during this process. This contraction is the visual evidence that the material has successfully densified.

Understanding the Trade-offs

Balancing Density and Dimensions

The primary trade-off in high-temperature sintering is between achieving full density and maintaining dimensional accuracy.

While the linear shrinkage of 13% to 20% is necessary for strength, it introduces complexity in manufacturing. The initial design must be scaled up precisely to account for this reduction, or the final part will be out of tolerance.

Thermal Risks

Operating near the melting point maximizes density but risks distortion.

If the temperature control is imprecise, or if the part is not supported correctly, the metal may soften too much. This can lead to warping or slumping under its own weight before the structure fully solidifies.

Optimizing Your Sintering Strategy

To ensure your components meet their performance criteria, consider the following regarding furnace operation:

- If your primary focus is mechanical integrity: Verify that the furnace reaches and holds the specific temperature required (e.g., 1300°C) to ensure full diffusion and the complete elimination of pores.

- If your primary focus is dimensional precision: Calculate your tooling and initial designs to strictly accommodate the expected 13% to 20% linear shrinkage.

The sintering furnace is not just a heater; it is the critical environment where powder becomes a true engineering material.

Summary Table:

| Process Phase | Primary Action | Key Temperature/Metric | Outcome |

|---|---|---|---|

| Thermal Debinding | Removal of binding agents | Controlled low-heat cycle | Purified metal structure |

| Sintering Stage | Atomic diffusion & grain growth | Approx. 1300°C | Solid-state bonding |

| Densification | Pore elimination | 13% - 20% Linear shrinkage | High mechanical strength |

| Final Cooling | Solidification | Controlled ramp down | Dimensional stability |

Elevate Your Material Performance with KINTEK

Precision in sintering is the difference between a fragile part and a high-performance engineering component. KINTEK provides the advanced thermal technology required to master atomic diffusion and shrinkage control.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab high-temp furnaces or fully customizable solutions tailored to your unique metallurgical requirements, KINTEK ensures your components achieve maximum density and structural integrity.

Ready to optimize your sintering process? Contact our technical experts today to find the perfect furnace for your application.

Visual Guide

References

- Tobias Rosnitschek, Stephan Tremmel. Dimensional Accuracy and Mechanical Characterization of Inconel 625 Components in Atomic Diffusion Additive Manufacturing. DOI: 10.3390/applmech5020022

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What are the advantages of using a vacuum oven for the drying treatment of cathode electrodes? Enhance Battery Performance

- What is the function of high-temperature sintering furnaces in the densification of Ga2O3:Er targets?

- What is the significance of vacuum sintering in metal processing, and how do continuous vacuum furnaces facilitate it? Unlock High-Purity Metal Parts

- What other applications do vacuum furnaces have? Unlock Advanced Material Processing Across Industries

- In which industries is vacuum brazing commonly applied? Essential for Aerospace, Medical, Automotive, and Electronics

- What are the core functions of dual-chamber vacuum heat treatment systems? Master Precision Gas Quenching

- Why is a vacuum drying oven required for lithium-sulfur battery electrodes? Ensure High-Purity Testing Results

- How does a vacuum furnace enable effective magnesium vapor collection? Master Zoned Temperature Control for High Purity