A vacuum drying oven is strictly required to ensure the complete removal of solvents and trace moisture that would otherwise compromise the battery's chemistry. Specifically, treating electrode plates at 60 °C under vacuum ensures that N-Methyl-2-pyrrolidone (NMP) and gases trapped within micropores are fully extracted without damaging the electrode structure.

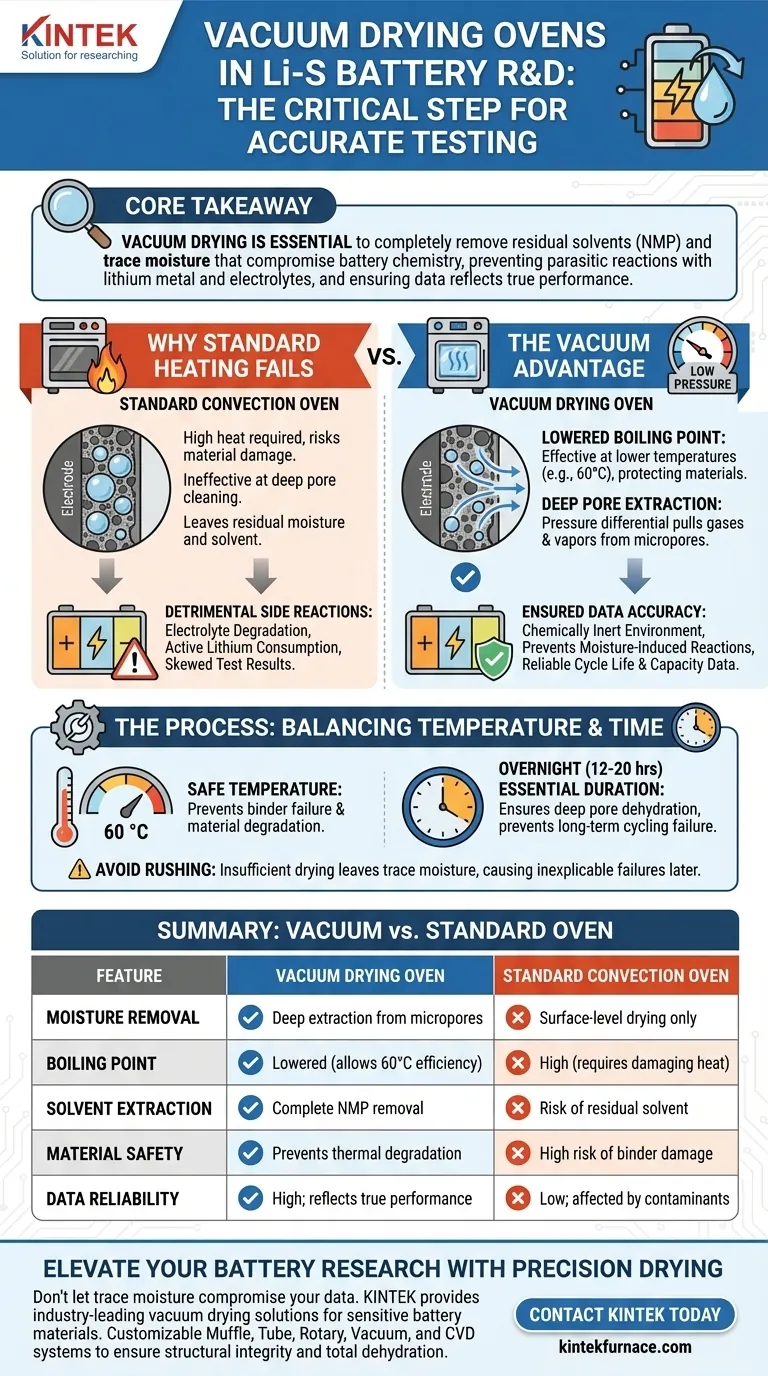

Core Takeaway The presence of even microscopic amounts of water or residual solvent causes parasitic side reactions with lithium metal and organic electrolytes. Vacuum drying is the only reliable method to deeply dehydrate the electrode's porous structure, ensuring that your electrochemical test data reflects the true performance of the material rather than artifacts caused by contamination.

The Critical Role of Dehydration and Solvent Removal

Eliminating Residual Solvents and Moisture

The primary function of the vacuum oven is the thorough removal of volatile components used during the manufacturing process.

Coated electrode plates retain residual solvents, such as N-Methyl-2-pyrrolidone (NMP), and physically adsorbed moisture. Because electrodes are porous, these contaminants often become trapped deep within the micropores, making them impossible to remove through simple air drying.

Preventing Detrimental Side Reactions

If moisture remains in the electrode, it becomes a distinct chemical hazard once the battery is assembled.

Water molecules react aggressively with lithium metal anodes and organic electrolytes. This leads to the degradation of the electrolyte and the consumption of active lithium, creating unstable byproducts that skew test results.

Ensuring Data Accuracy

For electrochemical testing to be valid, the environment must be chemically inert regarding contaminants.

Vacuum drying prevents these moisture-induced side reactions. By ensuring the electrode is chemically dry, you guarantee that the data collected regarding cycle life, capacity, and efficiency is a result of the battery design, not an error in preparation.

Why Vacuum is Superior to Standard Heating

Lowering the Boiling Point

Standard convection ovens rely on high heat to evaporate liquids, which can be damaging to sensitive battery components.

The vacuum environment significantly lowers the boiling point of solvents and water. This allows for rapid, effective drying at lower temperatures (such as 60 °C), protecting the electrode materials from thermal degradation or oxidation that might occur at higher temperatures.

Deep Pore Extraction

Heat alone often fails to clear the complex internal architecture of a battery electrode.

The pressure differential created by the vacuum pump physically pulls gases and vapors out of the micropores. This mechanical action is essential for clearing the deep internal structure of the electrode, ensuring no pockets of gas or moisture remain to disrupt ion transport.

Understanding the Trade-offs

Temperature vs. Structural Integrity

While heat accelerates drying, excessive temperatures can cause the active material to peel from the current collector or damage the polymeric binders.

You must balance the need for dryness with the thermal stability of your specific materials. The primary guideline suggests 60 °C, which is generally safe for preventing binder failure while still effectively removing NMP under vacuum.

Drying Time vs. Process Efficiency

Deep vacuum drying is not a rapid process; it typically requires overnight treatment (or 12-20 hours depending on the protocol).

Cutting this time short to speed up workflow is a common pitfall. Insufficient drying time leaves trace moisture in the deepest pores, which will inevitably surface during long-term cycling tests, causing inexplicable failure later in the research.

Making the Right Choice for Your Goal

To ensure your electrochemical testing yields publication-quality data, apply the following principles:

- If your primary focus is Initial Performance Data: Ensure you use a vacuum to lower the boiling point of solvents like NMP, preventing thermal damage that could skew initial capacity readings.

- If your primary focus is Long-Term Cycling Stability: Prioritize the duration of the drying process (overnight) to ensure deep pore dehydration, as trace moisture is the primary cause of electrolyte degradation over time.

Ultimate success in battery testing relies not just on the materials you choose, but on the rigorous elimination of the contaminants that destroy them.

Summary Table:

| Feature | Vacuum Drying Oven | Standard Convection Oven |

|---|---|---|

| Moisture Removal | Deep extraction from micropores | Surface-level drying only |

| Boiling Point | Lowered (allows 60°C efficiency) | High (requires damaging heat) |

| Solvent Extraction | Complete NMP removal | Risk of residual solvent |

| Material Safety | Prevents thermal degradation | High risk of binder damage |

| Data Reliability | High; reflects true performance | Low; affected by contaminants |

Elevate Your Battery Research with Precision Drying

Don't let trace moisture and residual solvents compromise your electrochemical data. KINTEK provides industry-leading vacuum drying solutions designed specifically for sensitive battery materials.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique laboratory needs. Whether you are scaling up production or conducting fundamental research, our high-temp furnaces ensure the structural integrity of your electrodes while achieving total dehydration.

Ready to optimize your testing preparation? Contact KINTEK today to find the perfect customizable furnace solution for your lab.

Visual Guide

References

- Ka Chun Li, Xijun Hu. Fe<sub>3</sub>O<sub>4</sub>@Fe Core–Shell Okara-Derived Activated Carbon for Superior Polysulfide Control in Lithium–Sulfur Batteries. DOI: 10.1021/acs.jpcc.5c02606

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is a high-vacuum sintering furnace essential for copper-iron composites? Achieve Pure, High-Density Results

- How do the drying conditions in a vacuum drying oven affect NiS2 electrode quality? Optimize Your Battery Performance

- What is the purpose of using industrial heating during non-productive vacuum degassing phases? Protect Your Assets

- What technical advantages do vacuum high-temperature furnaces provide for sandwich panel brazing? Achieve Stronger Bonds

- What are the disadvantages of using a vacuum furnace? High Costs, Material Limits, and More

- How is furnace brazing utilized in the medical and pharmaceutical industries? Ensure Sterile, Biocompatible Joints for Medical Devices

- How does high-temperature vacuum processing improve phosphor ceramics? Boost Thermal Stability in High-Power Lasers

- What is the purpose of utilizing a high vacuum system and vacuum sealing? Ensure Purity in Alloy Synthesis