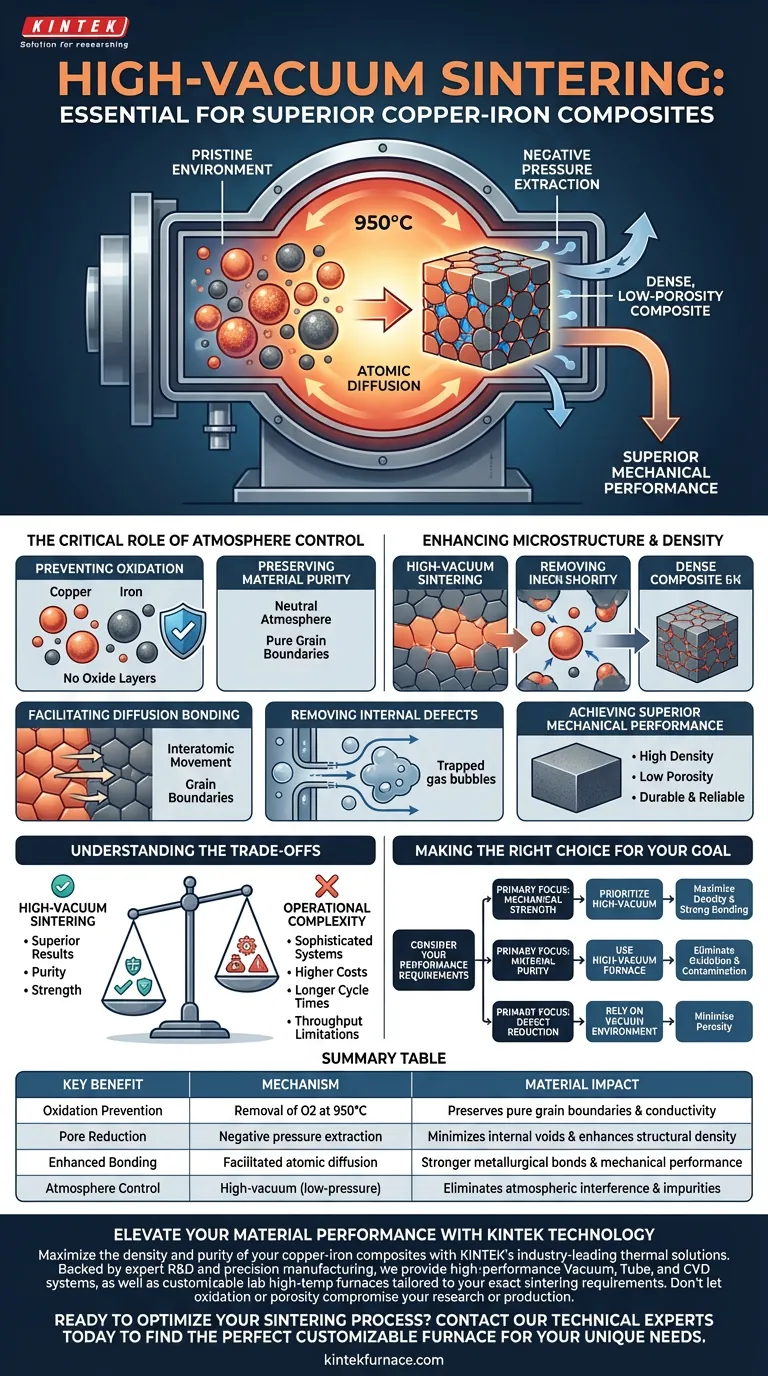

High-vacuum sintering creates a pristine, low-pressure environment critical for processing copper-iron composites. By operating at high temperatures (approximately 950°C) within a vacuum, the furnace prevents the oxidation of the metal matrix. Simultaneously, the negative pressure actively extracts internal gases and promotes atomic diffusion, ensuring a dense, low-porosity, and mechanically superior final product.

The essential value of a high-vacuum furnace lies in its ability to eliminate atmospheric interference. By removing oxygen and residual gases, it enables metal particles to bond at an atomic level, transforming loose powder into a solid, high-density composite without structural defects.

The Critical Role of Atmosphere Control

Preventing Matrix Oxidation

The primary challenge in sintering copper-iron composites is the reactivity of the metals. At the required processing temperature of 950°C, the copper matrix is highly susceptible to oxidation if exposed to air.

Preserving Material Purity

A high-vacuum environment acts as a neutral atmosphere. By eliminating oxygen from the chamber, the furnace prevents the formation of oxide layers on the copper and iron particles. This ensures that the grain boundaries remain pure, which is a prerequisite for strong metallurgical bonding.

Enhancing Microstructure and Density

Facilitating Diffusion Bonding

Solid-phase sintering relies on the movement of atoms between particles to create strength. The vacuum environment utilizes negative pressure to facilitate this diffusion bonding and wetting between the powder particles.

Removing Internal Defects

During the sintering process, trapped gases can create voids that weaken the material. The vacuum environment actively draws out these residual internal gases.

Achieving Superior Mechanical Performance

The removal of gases and the promotion of wetting result in a finished composite with high density and low porosity. This structural integrity directly translates to improved mechanical performance, making the material more durable and reliable.

Understanding the Trade-offs

Process Complexity and Cost

While high-vacuum sintering yields superior results, it introduces higher operational complexity compared to standard atmosphere sintering. Achieving and maintaining high vacuum levels requires sophisticated pumping systems and meticulous seal maintenance, which increases both initial capital investment and operational costs.

Throughput Limitations

Vacuum cycles often require significant time to pump down the chamber before heating begins and to cool down under vacuum to prevent re-oxidation. This can result in longer cycle times compared to continuous belt furnaces used in protective atmosphere sintering, potentially limiting throughput for high-volume production.

Making the Right Choice for Your Goal

To determine if high-vacuum sintering is the correct approach for your specific copper-iron application, consider your performance requirements.

- If your primary focus is mechanical strength: Prioritize high-vacuum sintering to maximize density and ensure strong diffusion bonding between the copper and iron phases.

- If your primary focus is material purity: Use a high-vacuum furnace to eliminate the risk of oxidation and grain boundary contamination, which degrades conductivity and strength.

- If your primary focus is defect reduction: Rely on the vacuum environment to extract residual gases, thereby minimizing porosity in the final component.

High-vacuum sintering is not merely a heating process; it is a purification and densification tool essential for high-performance composites.

Summary Table:

| Key Sintering Benefit | Mechanism | Material Impact |

|---|---|---|

| Oxidation Prevention | Removal of O2 at 950°C | Preserves pure grain boundaries and conductivity |

| Pore Reduction | Negative pressure extraction | Minimizes internal voids and enhances structural density |

| Enhanced Bonding | Facilitated atomic diffusion | Stronger metallurgical bonds and mechanical performance |

| Atmosphere Control | High-vacuum (low-pressure) | Eliminates atmospheric interference and impurities |

Elevate Your Material Performance with KINTEK Technology

Maximize the density and purity of your copper-iron composites with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and precision manufacturing, we provide high-performance Vacuum, Tube, and CVD systems, as well as customizable lab high-temp furnaces tailored to your exact sintering requirements. Don't let oxidation or porosity compromise your research or production.

Ready to optimize your sintering process? Contact our technical experts today to find the perfect customizable furnace for your unique needs.

Visual Guide

References

- Studying the Effect of Different Lubricant Materials on the Tribological Properties & Hardness of Cu-Fe Composite Prepared By PM. DOI: 10.47485/2832-9384.1048

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How do vacuum furnaces ensure clean and bright surfaces on materials? Achieve Purity and Precision in Thermal Processing

- What role does carbonization in a high-temperature furnace play for 2D COF membranes? Enhance Stability & Conductivity

- What role does a floating zone furnace play in high-purity superconducting growth? Achieve Crucible-Free Excellence

- What is the purpose of a vacuum sintering furnace? Create High-Performance Parts with Superior Purity

- Why is a high-vacuum environment necessary in copper slag impoverishment? Maximize Your Matte Separation Efficiency

- What is a gas heated vacuum furnace? Economical High-Temp Processing Solutions

- How can manufacturers select the appropriate sintering furnace for their needs? Optimize Your Production with the Right Equipment

- How does quenching work in a vacuum furnace and what is its purpose? Achieve Superior Material Properties