At its core, a vacuum furnace creates a clean surface by fundamentally altering the processing environment to remove the very elements that cause contamination. By evacuating the chamber of reactive gases like oxygen and carbon-bearing molecules, it prevents chemical reactions such as oxidation from occurring at high temperatures. This ensures the material retains its inherent brightness and chemical purity throughout the entire heating cycle.

A vacuum is not merely a tool for achieving a bright finish; it is a prerequisite for process control. It eliminates unwanted chemical reactions at elevated temperatures, protecting both the surface integrity and the underlying metallurgical properties of the material being treated.

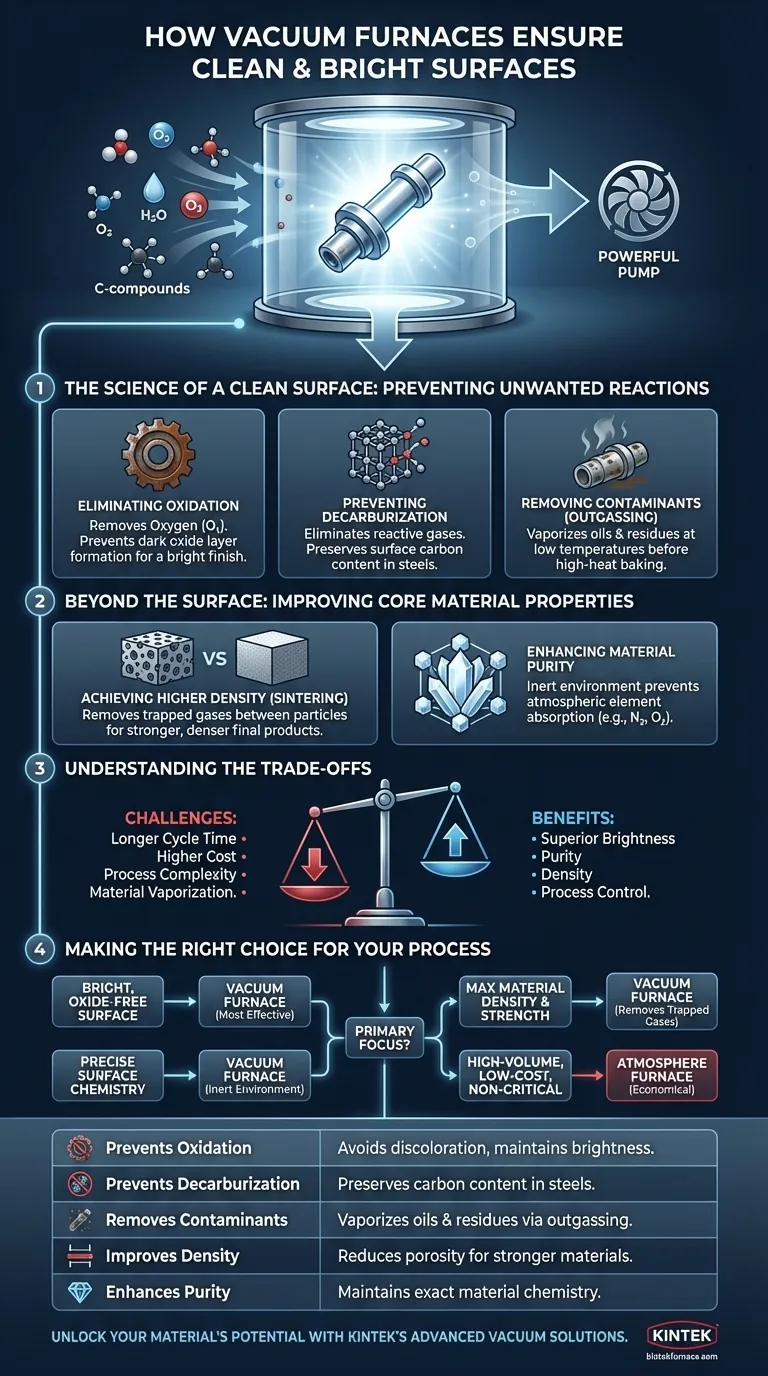

The Science of a Clean Surface: Preventing Unwanted Reactions

To understand why a vacuum is so effective, we must first recognize that a standard atmosphere is chemically reactive, especially when heated. A vacuum furnace works by removing these reactive elements.

Eliminating Oxidation

The most common cause of discoloration on metals is oxidation—the formation of a thin, often dark, layer of metal oxide when the material reacts with oxygen.

In a traditional furnace, the ambient air provides an abundant supply of oxygen. A vacuum furnace pumps this oxygen out, reducing the pressure to a point where there are too few oxygen molecules present to create a visible oxide layer, leaving the part’s surface bright and clean.

Preventing Decarburization

For high-carbon steels, another risk is decarburization, where carbon atoms migrate from the surface of the steel. This softens the material and degrades its wear resistance.

This reaction is often driven by trace amounts of oxygen or water vapor in the atmosphere. By creating a high-purity vacuum, these reactive gases are eliminated, preserving the precise carbon content of the material's surface.

Removing Surface Contaminants

The vacuum environment also actively cleans parts through a process known as outgassing.

As the furnace begins to heat under vacuum, volatile residues on the material's surface—such as oils, lubricants, or other contaminants from prior manufacturing steps—vaporize and are pumped away. This happens at low temperatures, long before they can bake onto or react with the part during the high-heat cycle.

Beyond the Surface: Improving Core Material Properties

The benefits of a vacuum environment extend deep into the material itself, enabling the creation of components with superior mechanical and structural properties.

Achieving Higher Density

In processes like sintering, where powdered materials are fused into a solid mass, trapped gases are a primary cause of porosity. Porosity weakens the final part.

A vacuum removes the atmospheric gases between the powder particles before they are heated. This allows the particles to bond more completely, resulting in a denser, stronger final product with near-theoretical density, which is critical for advanced ceramics and powdered metals.

Enhancing Material Purity

For industries like aerospace, medical, and electronics, material purity is non-negotiable. Even minuscule impurities can lead to component failure.

A vacuum furnace provides an inert environment that prevents atmospheric elements like oxygen and nitrogen from being absorbed into the material. This ensures the finished part maintains the exact, high-purity chemistry specified by its design.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all thermal processing. Understanding its limitations is key to using it effectively.

Cycle Time and Cost

Achieving a deep vacuum requires time for the pumps to evacuate the chamber, making cycle times longer than in a conventional atmosphere furnace. The equipment is also more complex and carries a higher initial investment and maintenance cost.

Process Complexity

Operating a vacuum furnace requires a higher level of technical control. Factors like the pump-down rate, vacuum level, and leak rate must be carefully managed to ensure repeatable, high-quality results. Improper operation can lead to subpar outcomes.

Material-Specific Behavior

Not all materials react to a vacuum in the same way. Certain alloying elements with a high vapor pressure can "outgas" from the base material at high temperatures, slightly altering the alloy's composition. This phenomenon, known as "vaporization," must be accounted for in the process parameters.

Making the Right Choice for Your Process

The decision to use a vacuum furnace should be driven by the specific requirements of your material and final application.

- If your primary focus is a bright, oxide-free surface finish: A vacuum furnace is the most effective method, as it directly removes the oxygen that causes discoloration.

- If your primary focus is maintaining precise surface chemistry: A vacuum provides an inert environment essential for preventing decarburization in steels or contamination in reactive metals.

- If your primary focus is maximizing material density and strength: For processes like sintering ceramics or brazing complex assemblies, a vacuum is critical for removing trapped gases and ensuring void-free results.

- If your primary focus is high-volume, low-cost heat treating of non-critical parts: A traditional atmosphere furnace may offer a more economical and higher-throughput solution.

Ultimately, a vacuum furnace transforms the processing atmosphere from a potential contaminant into a strategic tool for material perfection.

Summary Table:

| Key Benefit | Description |

|---|---|

| Prevents Oxidation | Removes oxygen to avoid discoloration and maintain surface brightness. |

| Prevents Decarburization | Eliminates reactive gases to preserve carbon content in steels. |

| Removes Contaminants | Uses outgassing to vaporize and pump away oils and residues. |

| Improves Density | Reduces porosity in sintering for stronger, denser materials. |

| Enhances Purity | Provides inert environment to maintain exact material chemistry. |

Unlock the full potential of your materials with KINTEK's advanced vacuum furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering clean, bright surfaces and superior material properties for industries like aerospace, medical, and electronics. Contact us today to discuss how we can enhance your thermal processing and achieve material perfection!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity