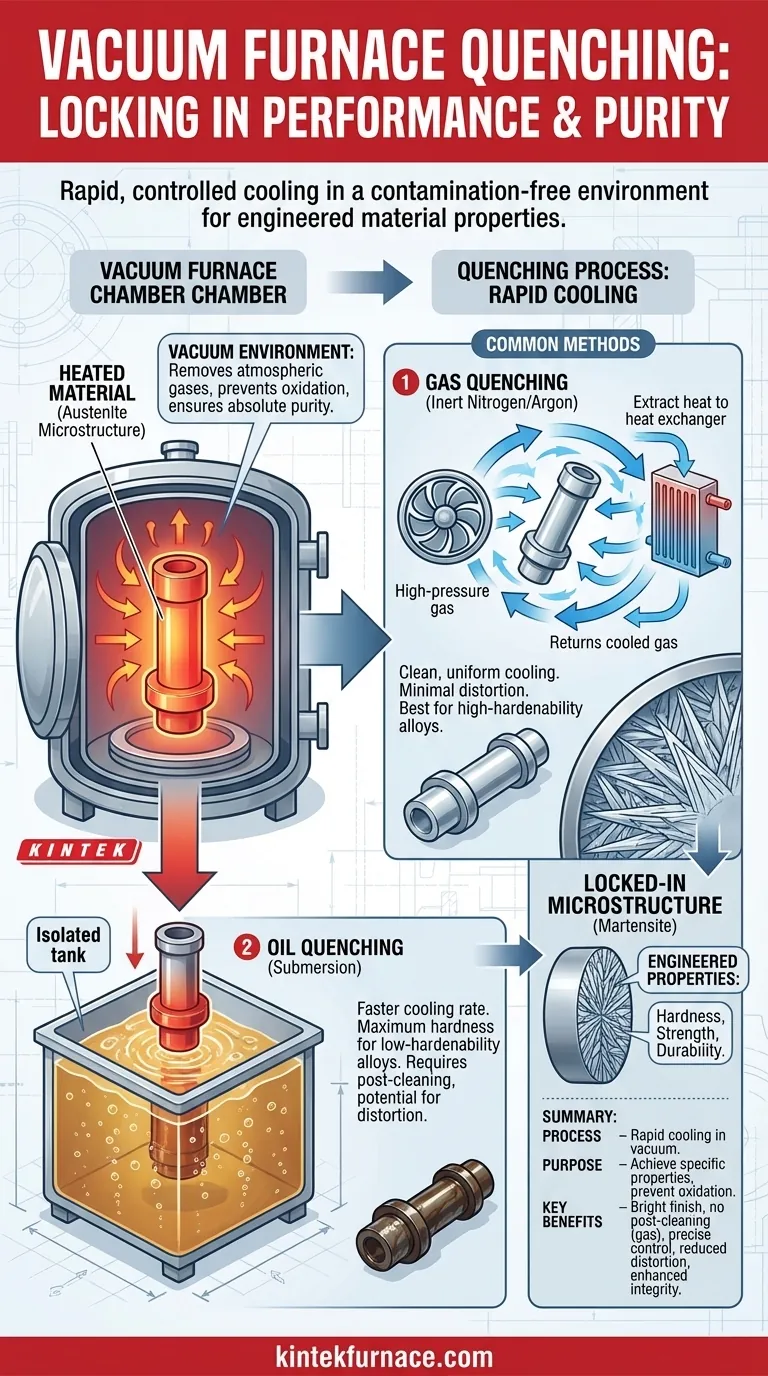

At its core, quenching in a vacuum furnace is the process of rapidly and uniformly cooling a heated material, typically a metal, within a controlled, contamination-free environment. This is most often achieved by introducing a high-pressure inert gas like nitrogen or argon. The purpose is to "lock in" a specific crystalline structure (microstructure) formed at high temperatures, which directly determines the material's final mechanical properties, such as hardness, strength, and durability.

The primary value of vacuum furnace quenching is not merely the rapid cooling, but the ability to achieve it in an ultraclean environment. This prevents surface oxidation and contamination, ensuring the final component has precisely the engineered properties intended, with a bright, clean finish.

Why a Vacuum Environment is the Foundation

To understand quenching, you must first understand the environment. A vacuum furnace removes atmospheric gases, creating a near-perfect space for heat treatment.

Eliminating Oxidation and Contamination

Heating metals in the presence of oxygen causes oxidation—the formation of a scale layer on the surface. A vacuum eliminates this entirely.

This ensures the finished part is bright and clean, requiring no subsequent cleaning operations. More importantly, it prevents surface defects and alterations to the alloy's chemistry, which can compromise performance.

Ensuring Absolute Process Purity

The vacuum environment is essential for processing reactive materials like titanium or superalloys, which would be ruined by exposure to air at high temperatures.

This purity guarantees that the properties achieved are a direct result of the thermal cycle, not a reaction with environmental contaminants.

The Mechanics of a Quench

Quenching is a carefully controlled thermal shock. Its goal is to manipulate the atomic structure of the metal before it has a chance to settle into its natural, slower-cooled state.

"Freezing" a High-Performance Microstructure

When a metal like steel is heated, its crystalline structure changes into a form called austenite. If cooled slowly, it reverts to softer, more ductile structures.

Rapid quenching forces the austenite to transform into a very hard, strong, but brittle structure called martensite. This is the fundamental goal for many hardening processes. The rate of cooling is the critical variable that determines the outcome.

The Role of Cooling Rate

Different alloys require different cooling speeds to achieve the desired transformation. This is known as an alloy's hardenability.

Too slow a quench will fail to produce the hardened structure. An unnecessarily fast quench can introduce internal stresses, leading to distortion or even cracking.

Common Quenching Methods in a Vacuum Furnace

The method of cooling is chosen based on the required quench rate for the specific alloy being treated.

Gas Quenching

This is the most common method in modern vacuum furnaces. After the part reaches its target temperature, the heating chamber is backfilled with a high-pressure inert gas (typically nitrogen or argon).

A powerful fan circulates this gas at high velocity through the workload, where it absorbs heat. The heated gas is then directed out of the chamber to a water-cooled heat exchanger before being recirculated back into the furnace. The pressure of the gas (from 2 to 20 bar or more) directly controls the cooling rate.

Oil Quenching

For alloys with lower hardenability that require a faster quench than gas can provide, oil quenching is used. These furnaces are designed with an isolated, sealed oil bath below or adjacent to the hot zone.

After heating, the material is mechanically transferred from the hot zone and submerged into the oil—all while maintaining the vacuum. This provides a much more severe and rapid quench.

Understanding the Trade-offs

Choosing a quenching method involves balancing speed, part quality, and process complexity.

Gas Quenching: Cleanliness and Control

The primary advantage of gas quenching is its cleanliness. Parts emerge bright and oil-free. It also provides more uniform cooling, which significantly reduces the risk of part distortion.

However, its cooling rate is slower than oil. It may not be sufficient to fully harden large cross-sections or certain types of tool steels.

Oil Quenching: Maximum Speed

Oil's key advantage is its speed and ability to achieve maximum hardness in less-hardenable alloys.

The downsides include the need for post-process part cleaning, the potential for greater thermal shock and distortion, and the added complexity and maintenance of the furnace's oil bath system.

Making the Right Choice for Your Goal

Your final decision depends on the material's requirements and your desired outcome.

- If your primary focus is a clean surface finish and minimal distortion on high-hardenability alloys: High-pressure gas quenching is the ideal choice.

- If your primary focus is achieving maximum hardness in low-hardenability alloys: Oil quenching is often the only viable method, despite the added process steps.

- If your primary focus is process repeatability and reliability: Any vacuum quench method offers superior control and consistency compared to atmospheric furnace treatments.

Ultimately, vacuum quenching transforms heat treatment from a bulk process into a precise engineering step for creating high-integrity, high-performance components.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | Rapid cooling of heated metal using inert gas or oil in a vacuum to lock in microstructure. |

| Purpose | Achieve specific mechanical properties like hardness and strength; prevent oxidation and contamination. |

| Common Methods | Gas quenching (clean, uniform cooling) and oil quenching (faster, for low-hardenability alloys). |

| Key Benefits | Bright finish, no post-cleaning, precise control, reduced distortion, and enhanced component integrity. |

Ready to elevate your material performance with precision quenching? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for diverse laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements. Contact us today to discuss how our expertise can optimize your heat treatment processes and deliver superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability