Selecting a sintering furnace is a foundational investment that directly impacts product quality, production capacity, and operational cost. The right choice is made by systematically evaluating your specific material properties and production requirements against key furnace capabilities such as temperature range, atmosphere control, processing capacity, and automation. This ensures the equipment is not just a capital expense, but a strategic asset aligned with your manufacturing goals.

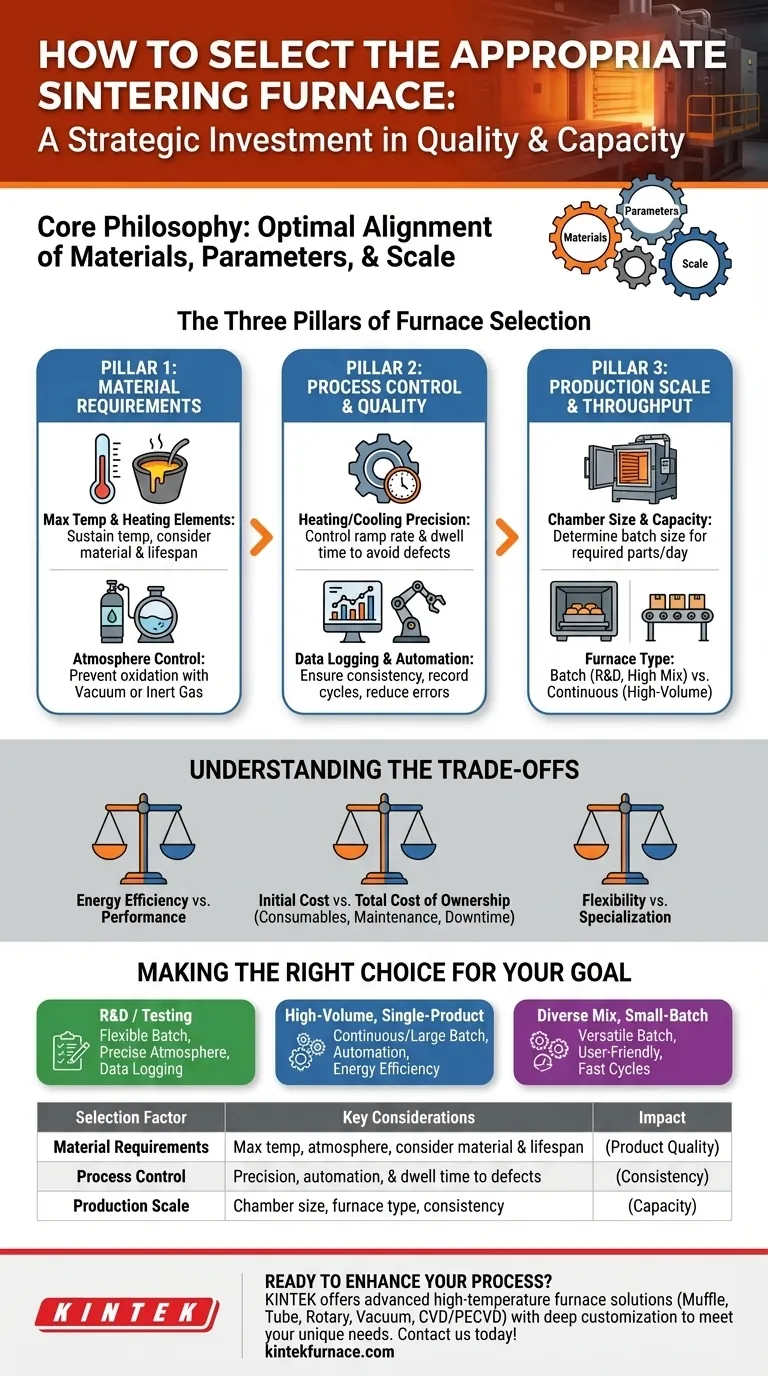

Your goal is not to find the single "best" furnace on the market. It is to identify the furnace that represents the optimal alignment between three critical factors: the materials you process, the parameters of your process, and the scale of your production.

The Three Pillars of Furnace Selection

A thorough evaluation process is built on three core pillars. Each one represents a set of non-negotiable requirements that will narrow your search and clarify your decision.

Pillar 1: Material Requirements

The material you are sintering dictates the fundamental performance specifications of the furnace.

Maximum Temperature and Heating Elements

Every material has a specific sintering temperature range. Your furnace must be able to comfortably reach and sustain this temperature, with a buffer for future material development. The heating element material (e.g., Kanthal, SiC, MoSi2) determines the furnace's maximum temperature, lifespan, and ramp rate.

Atmosphere Control

Many advanced materials, especially metals, will oxidize or react undesirably if heated in ambient air. Atmosphere control is essential for preventing these defects. Determine if your process requires a vacuum, an inert gas (like Argon or Nitrogen), or a specific reactive gas environment.

Pillar 2: Process Control and Quality

Repeatability and precision are the cornerstones of quality manufacturing. The furnace's control system is central to achieving this.

Heating and Cooling Precision

The ability to precisely control the rate of temperature change (ramp rate) and hold it at specific temperatures (dwell time) is critical. Poor control can lead to thermal shock, cracking, or incomplete sintering. Look for furnaces with multi-stage programming to build complex and repeatable heating profiles.

Data Logging and Automation

For quality assurance and process optimization, data logging is invaluable. It provides a verifiable record of every production cycle. Automation capabilities reduce the potential for human error, improve consistency, and lower labor costs, especially in multi-shift operations.

Pillar 3: Production Scale and Throughput

Your furnace must match your business's production demands, both now and in the future.

Chamber Size and Capacity

The internal workspace or chamber size dictates your batch size. Calculate your required throughput in terms of parts per day or week to determine the necessary processing capacity. Always consider future growth in your calculations.

Furnace Type: Batch vs. Continuous

Batch furnaces process one load at a time and are ideal for R&D, small-series production, or a high mix of different parts. Continuous furnaces (like rotary tube or walking beam furnaces) move parts through heating zones on a conveyor, offering higher throughput for standardized, high-volume production.

Understanding the Trade-offs

Every furnace design involves compromises. Being aware of them allows you to make an informed decision based on your priorities.

Energy Efficiency vs. Performance

High-performance furnaces that reach extreme temperatures or have very fast ramp rates are often less energy-efficient. Evaluate the quality of the insulation and the power consumption ratings to understand the long-term operational costs.

Initial Cost vs. Total Cost of Ownership

The sticker price is only one part of the equation. Consider the cost and lifespan of consumables like heating elements and thermocouples. Factor in the recommended maintenance schedule, service availability, and the potential cost of downtime.

Flexibility vs. Specialization

A general-purpose batch furnace offers great flexibility for processing different materials and part geometries. However, a highly specialized continuous furnace will almost always be more efficient and cost-effective for mass-producing a single product.

Making the Right Choice for Your Goal

Use your primary objective to guide your final decision.

- If your primary focus is R&D or material testing: Prioritize a flexible batch furnace with advanced programming, precise atmosphere control, and comprehensive data logging.

- If your primary focus is high-volume, single-product manufacturing: Prioritize a continuous or large-batch furnace with high automation, robust construction, and excellent energy efficiency.

- If your primary focus is producing a diverse mix of small-batch parts: Prioritize a versatile batch furnace with user-friendly programming and fast cooling cycles to minimize changeover time.

Choosing the right sintering furnace is an investment in your process capability and product quality for years to come.

Summary Table:

| Selection Factor | Key Considerations |

|---|---|

| Material Requirements | Max temperature, heating elements, atmosphere control (vacuum, inert gas) |

| Process Control | Heating/cooling precision, data logging, automation for repeatability |

| Production Scale | Chamber size, throughput, batch vs. continuous furnace type |

| Trade-offs | Energy efficiency vs. performance, initial vs. total cost, flexibility vs. specialization |

Ready to enhance your manufacturing process with a tailored sintering furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs, boosting efficiency and quality. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents