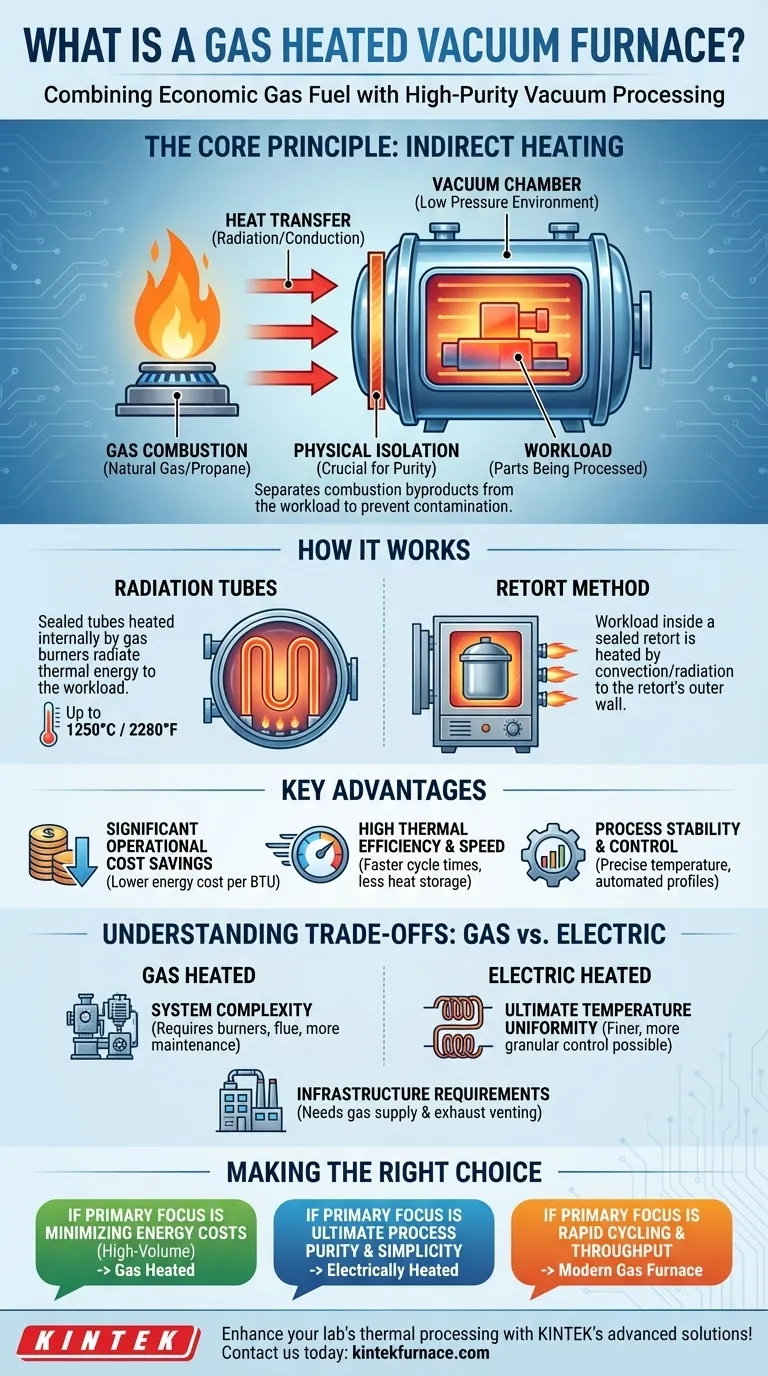

In essence, a gas heated vacuum furnace is a specialized thermal processing system that uses the combustion of gas (like natural gas or propane) to heat parts within a controlled, low-pressure (vacuum) environment. Crucially, this heating is always indirect—the flame and combustion byproducts are kept entirely separate from the workload, preserving the purity of the vacuum atmosphere.

The core concept is to combine the economic advantage of gas fuel with the high-purity processing environment of a vacuum. It achieves this by physically isolating the gas combustion from the main vacuum chamber, transferring heat through radiation or conduction.

The Core Principle: Indirect Heating

The defining characteristic of a gas heated vacuum furnace is that the combustion process never occurs inside the main chamber. This separation is fundamental to its function.

Why Indirect Heating is Crucial

A vacuum is used in heat treating to prevent oxidation, contamination, and unwanted chemical reactions on the surface of the parts being processed.

Introducing a direct flame would flood the chamber with oxygen, carbon dioxide, and water vapor—the very contaminants the vacuum is meant to eliminate. Therefore, the heat must be generated outside the vacuum and transferred inward.

How It Works: Radiation Tubes

A common method involves vacuum-tight radiation tubes. These are sealed metal tubes that pass through or surround the furnace's vacuum chamber.

Gas is burned inside these tubes, causing them to glow red-hot (up to 1250°C / 2280°F). The tubes then radiate their thermal energy inward, heating the workload inside the vacuum chamber without any physical contact or atmospheric mixing.

How It Works: The Retort Method

Another design uses a retort, which is a sealed, gas-tight container (often made of a high-temperature alloy) that holds the workload.

This entire sealed container is placed inside a larger, conventional gas-fired furnace. Heat from the burners transfers by convection and radiation to the outer wall of the retort and then conducts through the wall to heat the parts held in the vacuum inside.

Key Advantages of This Approach

Combining gas fuel with a vacuum process offers a unique set of operational benefits, especially when compared to traditional electrically heated vacuum furnaces.

Significant Operational Cost Savings

For many industrial facilities, natural gas is a less expensive energy source per BTU than electricity. This can lead to substantial cost reductions, particularly in large-scale or continuous production environments.

High Thermal Efficiency and Speed

Modern gas-fired systems feature low thermal mass designs, meaning they have less "heat storage" than older, heavily insulated refractory furnaces.

This allows for faster temperature rise and fall rates, which shortens cycle times, increases throughput, and reduces wasted energy during heat-up and cool-down.

Process Stability and Control

Contrary to older designs, modern gas burner technology offers highly stable and precise temperature control. Automated systems can reliably maintain setpoints and execute complex heating profiles, ensuring consistent and repeatable results.

Understanding the Trade-offs: Gas vs. Electric

While cost-effective, gas heated systems are not the universal solution. The choice between gas and electric heating involves clear trade-offs.

System Complexity and Maintenance

Gas heated furnaces involve a fuel delivery system, burners, ignition controls, and an exhaust/flue system. This adds a layer of mechanical complexity and potential maintenance points compared to the relative simplicity of electric resistance heating elements.

Ultimate Temperature Uniformity

While modern gas radiation tube designs offer excellent temperature uniformity, multi-zone electric furnaces can often provide finer, more granular control over the temperature distribution within the hot zone. For extremely sensitive or complex geometries, electric heating may have an edge.

Infrastructure and Facility Requirements

Operating a gas heated furnace requires a reliable, high-volume natural gas or propane supply and proper infrastructure for venting combustion exhaust gases safely. An all-electric furnace avoids these requirements, simplifying installation in certain facilities.

Making the Right Choice for Your Process

Selecting the right furnace technology depends entirely on your specific operational goals, facility logistics, and process requirements.

- If your primary focus is minimizing operational energy costs for high-volume production: A gas heated vacuum furnace is a powerful and economically compelling option.

- If your primary focus is ultimate process purity, simplicity, and granular temperature control: An electrically heated vacuum furnace often provides a simpler, more controlled environment.

- If your primary focus is rapid cycling and maximizing throughput: A modern, low-thermal-mass gas furnace can offer a significant advantage in cycle time over older, refractory-lined designs.

Ultimately, understanding how these systems transfer heat is the key to choosing the technology that best aligns with your technical and financial objectives.

Summary Table:

| Aspect | Details |

|---|---|

| Heating Method | Indirect via radiation tubes or retort, isolating combustion from vacuum chamber |

| Temperature Range | Up to 1250°C (2280°F) |

| Key Advantages | Cost savings, high thermal efficiency, fast cycling, stable control |

| Ideal For | High-volume production, rapid throughput, energy cost reduction |

| Limitations | Higher complexity, maintenance needs, infrastructure requirements |

Enhance your lab's thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our gas heated vacuum furnaces can optimize your operations and reduce costs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity