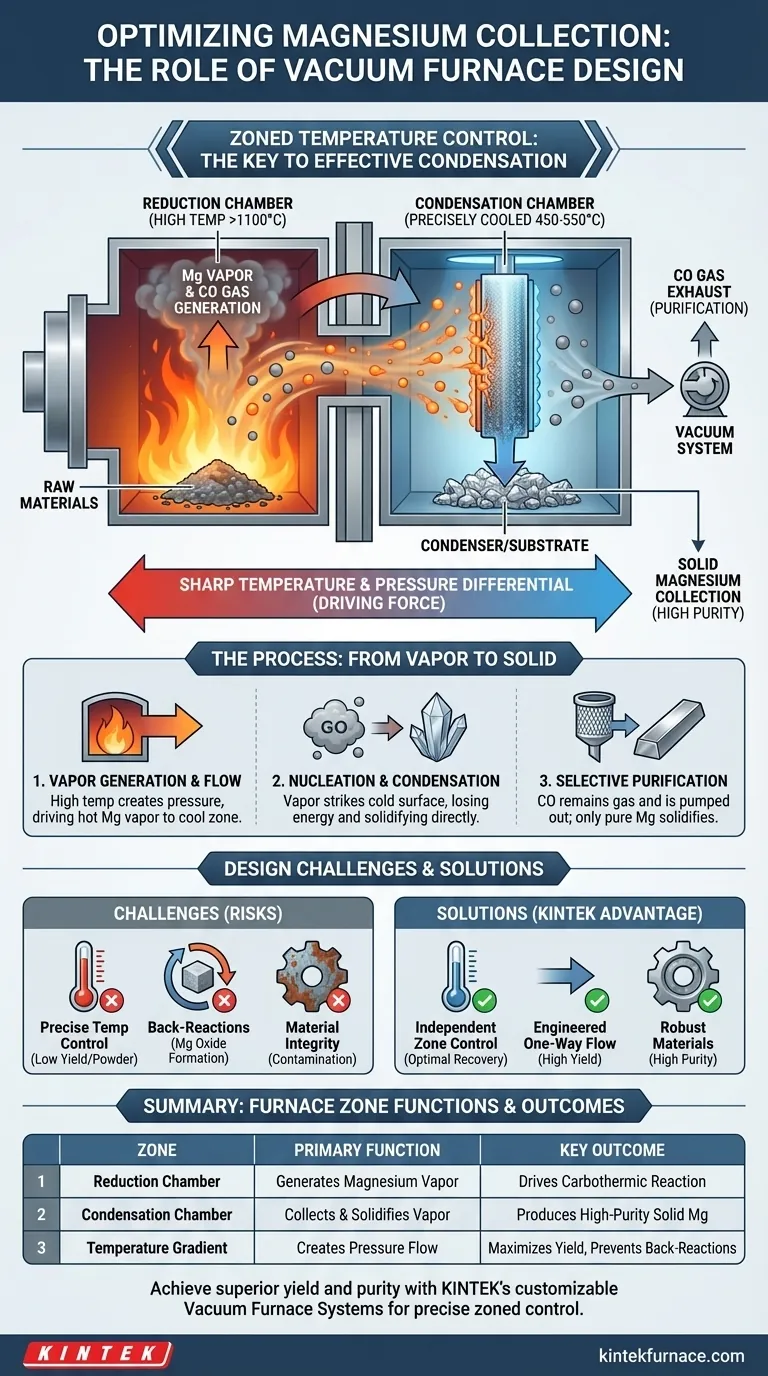

A well-designed vacuum furnace enables effective magnesium collection by creating a sharp, controlled temperature difference between two distinct areas. It uses a high-temperature reduction chamber to produce magnesium vapor and a separate, much cooler condensation chamber that acts as a target, forcing the vapor to solidify into pure metal.

The entire process hinges on a fundamental design principle: physically separating the high-temperature reaction that creates the vapor from a precisely cooled surface designed for its collection. This engineered temperature gradient is the key to maximizing both the yield and purity of the final magnesium product.

The Core Principle: Zoned Temperature Control

The furnace's effectiveness is not based on a single heated chamber but on a system of carefully managed thermal zones. This separation is the most critical aspect of the design.

The Reduction Chamber: Generating the Vapor

The process begins in the reduction chamber, which is heated to extremely high temperatures. This heat provides the energy needed for the carbothermic reduction reaction, converting solid raw materials into hot magnesium vapor and carbon monoxide gas.

The Condensation Chamber: The Collection Point

Connected to the reduction chamber is the condensation chamber. This zone is actively cooled and maintained at a specific, much lower temperature. It serves as the designated endpoint for the magnesium vapor's journey.

The Driving Force: Pressure and Temperature Differentials

The high temperature in the reduction chamber creates a higher vapor pressure. Driven by this pressure differential and the overall vacuum, the hot magnesium vapor naturally flows from the hot zone toward the cooler, lower-pressure condensation chamber.

How Condensation is Optimized

Simply cooling the vapor is not enough; the process must be controlled to ensure the magnesium is collected in a useful, pure form.

Nucleation on the Substrate

Inside the cooler condensation chamber is a specially designed condenser or substrate. When the hot magnesium gas molecules strike this cold surface, they rapidly lose energy, causing them to nucleate—transitioning directly from a gas to a solid state and forming initial crystals.

Separation from Byproducts

This phase change is highly selective. The magnesium condenses into a solid, while the primary byproduct, carbon monoxide (CO), remains a gas at these temperatures. The furnace's vacuum system continuously pumps out the CO gas, effectively purifying the collected magnesium.

Ensuring High Product Quality

By carefully controlling the condenser's temperature, engineers can influence the crystal structure and density of the solid magnesium. This prevents the formation of undesirable powder and ensures a high-quality metallic product is recovered.

Understanding the Design Challenges

Achieving this process efficiently presents several engineering challenges. A poor design will lead to low yield, low purity, or both.

Temperature Control is Non-Negotiable

If the condensation zone is too hot, the magnesium vapor will not condense effectively, leading to poor recovery rates. If it's too cold, it can cause rapid, uncontrolled nucleation that results in a fine powder instead of a solid mass. Precise, independent temperature control of each zone is essential.

Preventing Back-Reactions

The design must ensure a clear, one-way flow of vapor. If the temperature gradient is not properly established, magnesium vapor can mix with the outgoing carbon monoxide, potentially leading to back-reactions that re-form magnesium oxide and drastically reduce the process yield.

Material Integrity

The materials used for both chambers and the condenser must withstand extreme temperatures and the corrosive environment created by the magnesium vapor. Any degradation or outgassing from these components could contaminate the final product.

Key Design Goals for Effective Magnesium Collection

To apply this understanding, consider your primary objective.

- If your primary focus is maximizing yield: Your design must create the steepest and most stable temperature gradient possible to drive nearly all the vapor to the condenser.

- If your primary focus is achieving high purity: You must prioritize extremely precise temperature control in the condensation zone to selectively solidify magnesium while allowing all other gases to be pumped away.

- If your primary focus is process reliability: The design must feature robust and completely independent heating and cooling systems for each zone, ensuring consistent and repeatable results.

Ultimately, mastering the flow of heat is how a simple furnace is transformed into a highly efficient metallurgical refinery.

Summary Table:

| Furnace Zone | Temperature | Primary Function | Key Outcome |

|---|---|---|---|

| Reduction Chamber | Very High (e.g., >1100°C) | Generates Magnesium Vapor | Drives the carbothermic reaction |

| Condensation Chamber | Precisely Cooled (e.g., 450-550°C) | Collects and Solidifies Vapor | Produces high-purity, solid magnesium |

| Temperature Gradient | Sharp Difference | Creates a pressure/vapor flow | Maximizes yield and prevents back-reactions |

Ready to achieve superior yield and purity in your metallurgical processes?

Backed by expert R&D and manufacturing, KINTEK offers a range of high-performance Vacuum Furnace Systems designed for precise zoned temperature control, ensuring effective condensation and collection of volatile metals like magnesium. Our furnaces are customizable to meet your unique process requirements, whether your focus is on maximizing yield, achieving the highest purity, or ensuring long-term reliability.

Contact our experts today to discuss how a KINTEK vacuum furnace can optimize your lab's efficiency and results.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production