The primary role of a muffle furnace in biochar studies is to provide the controlled high-temperature environment necessary for thermal regeneration. Specifically, it is used to heat spent biochar to approximately 450°C for short durations, such as 20 minutes. This process thermally decomposes or desorbs organic pollutants (like Metronidazole) trapped within the biochar's pores, effectively restoring its adsorption capacity.

Core Takeaway A muffle furnace does more than just heat samples; it acts as a validation tool for the economic viability of biochar. By proving that biochar can be successfully regenerated and reused rather than discarded, researchers demonstrate its potential for sustainable, industrial-scale water treatment.

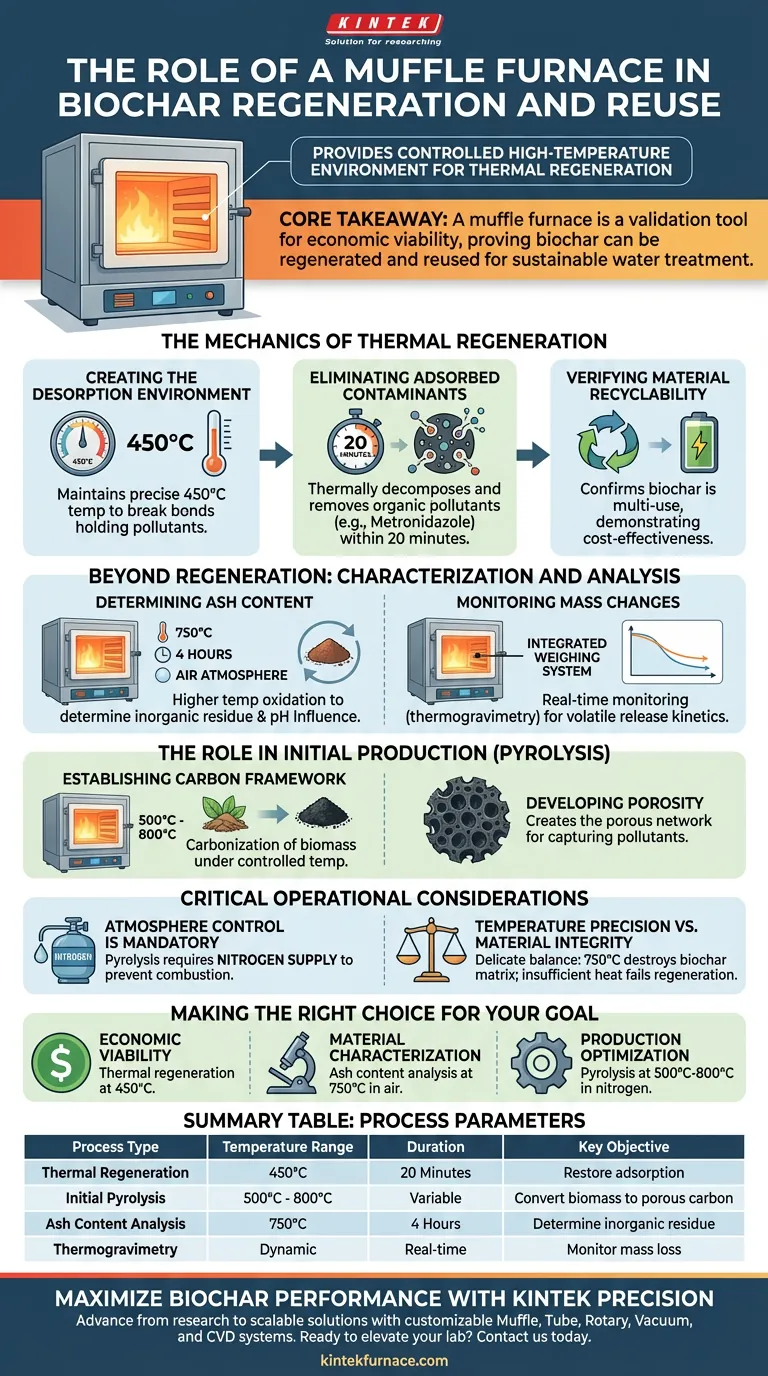

The Mechanics of Thermal Regeneration

Creating the Desorption Environment

The muffle furnace allows researchers to maintain a precise temperature, typically around 450°C, which is critical for regeneration.

At this specific thermal range, the bonds holding organic pollutants to the biochar are broken.

Eliminating Adsorbed Contaminants

During a standard 20-minute heat treatment, the furnace ensures the complete thermal decomposition of contaminants.

For example, organic pollutants like Metronidazole that have been adsorbed into the biochar's porous structure are effectively removed.

Verifying Material Recyclability

The ultimate goal of this process is to confirm that the biochar can be used for multiple cycles.

Successful regeneration in the furnace proves that the material does not need to be single-use, which is a major factor in assessing its cost-effectiveness for industry.

Beyond Regeneration: Characterization and Analysis

While regeneration is the primary focus for reuse studies, the muffle furnace is also utilized to characterize the material's fundamental properties.

Determining Ash Content

To understand the composition of the biochar, researchers heat samples to much higher temperatures, typically 750°C, for extended periods (e.g., 4 hours).

This process occurs in an air atmosphere to completely oxidize and volatilize all organic components.

The remaining inorganic residue represents the ash content, a critical indicator that influences the biochar's pH levels and how it interacts electrostatically with water.

Monitoring Mass Changes

When equipped with an integrated weighing system, a muffle furnace can perform thermogravimetric analysis.

This allows for real-time monitoring of sample mass as it is heated.

Researchers use this data to characterize volatile release kinetics, helping them identify the optimal holding times required to ensure consistent biochar quality.

The Role in Initial Production (Pyrolysis)

Before biochar can be regenerated, it must be synthesized correctly, a process often performed in the same furnace equipment.

Establishing the Carbon Framework

The furnace provides temperatures ranging from 500°C to 800°C to facilitate the carbonization of biomass, such as cotton waste or pulse-based residues.

This thermal decomposition removes volatile components and constructs the fixed carbon skeleton.

Developing Porosity

By maintaining these temperatures, the furnace transforms raw biomass into a structure rich in pores.

This porous network is the foundation of the biochar's ability to capture pollutants in the first place.

Critical Operational Considerations

Atmosphere Control is Mandatory

When producing or regenerating biochar, the atmosphere inside the furnace determines the outcome.

For pyrolysis (production), a nitrogen supply is critical to purge oxygen and create an anaerobic environment.

Without this oxygen exclusion, the biomass would simply undergo combustion (burn away) rather than converting into porous carbon.

Temperature Precision vs. Material Integrity

There is a delicate trade-off between removing impurities and destroying the material.

Heating too aggressively (e.g., reaching ash-content analysis temperatures of 750°C during a regeneration attempt) will destroy the biochar matrix.

Conversely, insufficient heat will fail to decompose the adsorbed pollutants, rendering the "regeneration" cycle ineffective.

Making the Right Choice for Your Goal

Using a muffle furnace in biochar research requires aligning your thermal protocol with your specific objective.

- If your primary focus is Economic Viability: Prioritize testing thermal regeneration at 450°C to prove the material can be recycled for multiple water treatment cycles.

- If your primary focus is Material Characterization: Use high-temperature oxidation (750°C in air) to determine ash content and inorganic residue composition.

- If your primary focus is Production Optimization: Ensure your furnace supports controlled atmospheric conditions (nitrogen purging) to prevent combustion during the 500°C–800°C pyrolysis phase.

Mastering the use of the muffle furnace allows you to bridge the gap between theoretical material synthesis and practical, scalable environmental solutions.

Summary Table:

| Process Type | Temperature Range | Duration | Key Objective |

|---|---|---|---|

| Thermal Regeneration | 450°C | 20 Minutes | Restore adsorption by removing organic pollutants |

| Initial Pyrolysis | 500°C - 800°C | Variable | Convert biomass into porous carbon framework |

| Ash Content Analysis | 750°C | 4 Hours | Determine inorganic residue and pH influence |

| Thermogravimetry | Dynamic | Real-time | Monitor mass loss and volatile release kinetics |

Maximize Biochar Performance with KINTEK Precision

Transition from theoretical research to scalable environmental solutions with KINTEK’s advanced thermal technology. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of biochar pyrolysis and regeneration.

Whether you are verifying economic viability at 450°C or conducting high-temperature ash analysis at 750°C, our furnaces provide the atmospheric control and temperature precision necessary to protect your carbon framework.

Ready to elevate your lab’s efficiency? Contact us today to find your custom heating solution.

Visual Guide

References

- Caio Henrique da Silva, Wardleison Martins Moreira. Synthesis of Activated Biochar from the Bark of Moringa oleifera for Adsorption of the Drug Metronidazole Present in Aqueous Medium. DOI: 10.3390/pr12030560

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What types of controllers are used in muffle furnaces? Choose the Right One for Precise Thermal Control

- What are the key components of a muffle furnace? Uncover the Core Parts for Precise High-Temperature Control

- How does a muffle furnace work? A Guide to Clean, Uniform Heat Treatment

- Why is precise temperature control in a muffle furnace essential during the secondary calcination of acid-etched catalysts?

- Why is a heating furnace required for thermal holding before hot extrusion? Optimize Material Flow & Density

- What is the function of a laboratory programmable furnace in biomass proximate analysis? Optimize Your Fuel Characterization

- What is the mechanism of a box muffle furnace in the preparation of active magnesium oxide powder? Expert Guide

- What is a box type furnace? A Versatile Tool for High-Temperature Batch Processing