At their core, muffle furnace controllers are distinguished by their level of automation and precision. Muffle furnaces use controllers that range from simple manual dials to highly sophisticated digital systems. The most common modern types are digital setpoint controllers, which maintain a single temperature, and programmable controllers, which can execute complex, multi-stage heating and cooling profiles using PID regulation for high accuracy.

The choice of a controller is not about features, but about process requirements. A simple setpoint controller is sufficient for basic heating, but a programmable controller is essential for automating the precise thermal ramps and soaks demanded by advanced materials science and complex heat-treating protocols.

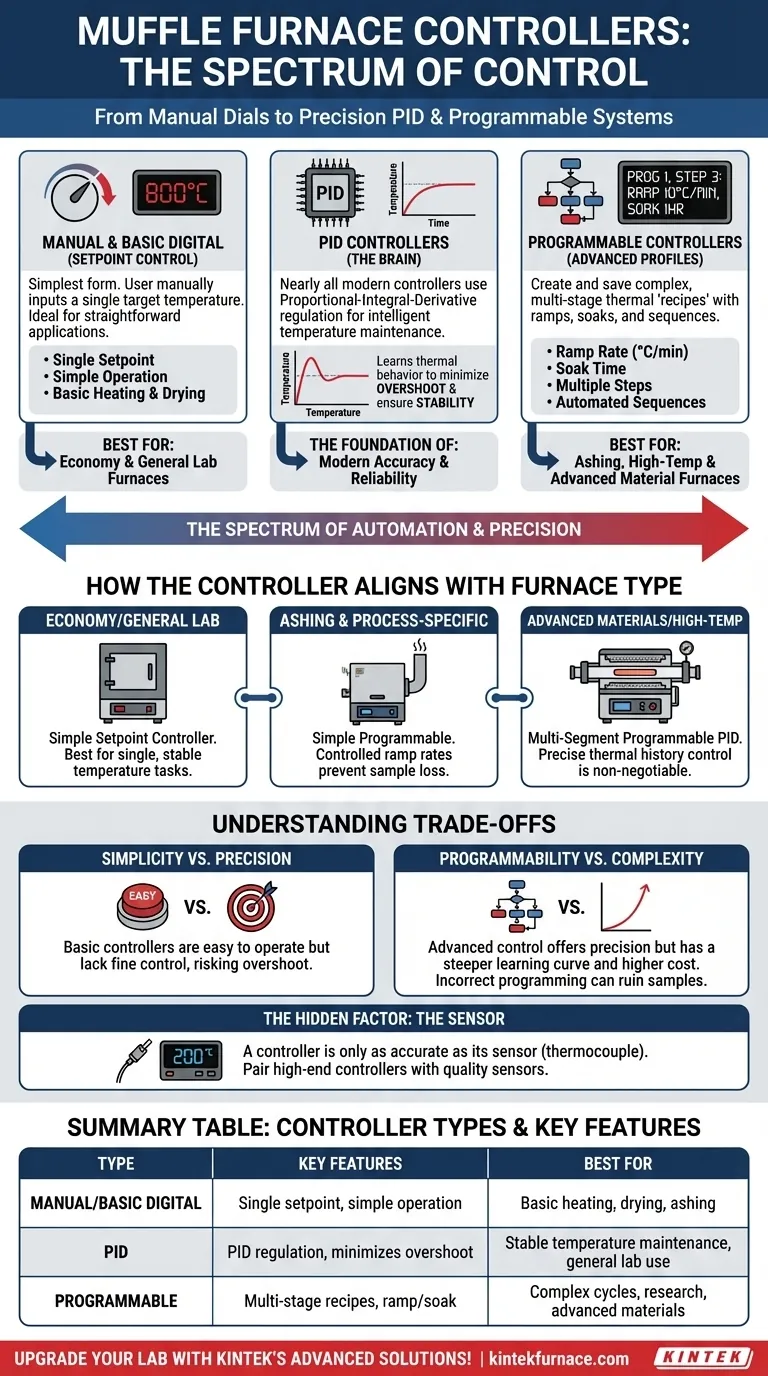

The Spectrum of Control: From Manual to Automated

Understanding the different controller types is about understanding the level of control you need over your thermal process. They exist on a spectrum from basic manual input to fully automated, multi-step recipes.

Manual and Basic Digital Controllers (Setpoint Control)

The simplest controllers, sometimes found on older or very basic economy models, include pointer tables or simple digital displays. These are setpoint controllers.

You manually input a single target temperature (the setpoint), and the controller works to reach and maintain it. These are ideal for straightforward applications where one stable temperature is all that is required.

PID Controllers: The Brains of Modern Furnaces

Nearly all modern digital controllers use PID (Proportional-Integral-Derivative) regulation. This is not a type of display, but the underlying intelligent method the controller uses to maintain temperature.

Think of it as an advanced cruise control system. It doesn't just turn the heat on and off around your setpoint; it learns the furnace's thermal behavior to minimize temperature overshoot and maintain exceptional stability.

PID logic is what gives modern furnaces their accuracy and reliability, whether they are simple setpoint models or fully programmable ones.

Programmable Controllers: Automating Complex Profiles

Programmable controllers are the most advanced option. They allow you to create and save multi-stage "recipes" or thermal profiles.

These controllers manage not just the final temperature, but also:

- Ramp Rate: How quickly the furnace heats up or cools down (°C/minute).

- Soak Time: How long the furnace holds at a specific temperature.

- Multiple Steps: The ability to string together multiple ramps and soaks into an automated sequence.

This level of control is critical for processes where the rate of temperature change is as important as the final temperature itself.

How the Controller Aligns with Furnace Type

The type of controller installed in a furnace is a direct reflection of its intended application and cost.

Economy and General Lab Furnaces

These units, designed for general-purpose heating, melting, or simple heat treatments, most often use a basic digital setpoint controller. The operator needs to achieve a single, stable temperature, and the simplicity and low cost of a setpoint controller are a perfect match.

Ashing and Process-Specific Furnaces

Ashing furnaces, which are used to determine the inorganic content of a sample, may benefit from simple programmable control. A slow, controlled ramp rate can prevent the sample from sputtering or being lost due to turbulent air exchange. A single-program, multi-step controller is common here.

High-Temperature and Advanced Material Furnaces

Furnaces designed for research, industrial production, or advanced materials (like Carbolite models reaching 3000°C) almost exclusively use multi-segment programmable PID controllers. In these applications, the thermal history of the material dictates its final properties. The ability to precisely and repeatably control every stage of the heating and cooling cycle is non-negotiable.

Understanding the Trade-offs

Choosing or using a furnace requires acknowledging the trade-offs inherent in its control system.

Simplicity vs. Precision

A basic setpoint controller is incredibly easy to operate but lacks the fine control needed for sensitive processes. It may overshoot the target temperature before settling, which could be detrimental to some materials.

Programmability vs. Complexity

Programmable controllers offer unparalleled precision and automation, enabling "set it and forget it" operation for complex cycles. However, this capability introduces a steeper learning curve and a higher initial cost. Incorrectly programming a cycle can also lead to ruined samples.

The Hidden Factor: The Sensor

A controller is only as accurate as the information it receives. Its decisions are based on data from a thermocouple (the temperature sensor). A high-end programmable controller paired with a low-grade or aging thermocouple will never deliver precise results.

Making the Right Choice for Your Goal

Your ideal controller depends entirely on the thermal process you need to execute.

- If your primary focus is simple, single-temperature applications: A basic digital setpoint controller offers the best balance of ease of use and sufficient accuracy for tasks like drying, ashing, or basic tempering.

- If your primary focus is complex, multi-stage thermal cycles: A multi-segment programmable PID controller is essential for the repeatability and precision required in research, materials development, or advanced manufacturing.

Understanding your controller empowers you to move from simply heating a sample to precisely engineering a thermal outcome.

Summary Table:

| Controller Type | Key Features | Best For |

|---|---|---|

| Manual/Basic Digital | Single setpoint, simple operation | Basic heating, drying, ashing |

| PID | Proportional-Integral-Derivative regulation, minimizes overshoot | Stable temperature maintenance, general lab use |

| Programmable | Multi-stage recipes, ramp rates, soak times | Complex cycles, research, advanced materials |

Upgrade your lab's thermal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs. Contact us today to discuss how our controllers can enhance your precision and efficiency!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a high-temperature muffle furnace in silver nanoparticle circuits? Optimize Conductivity