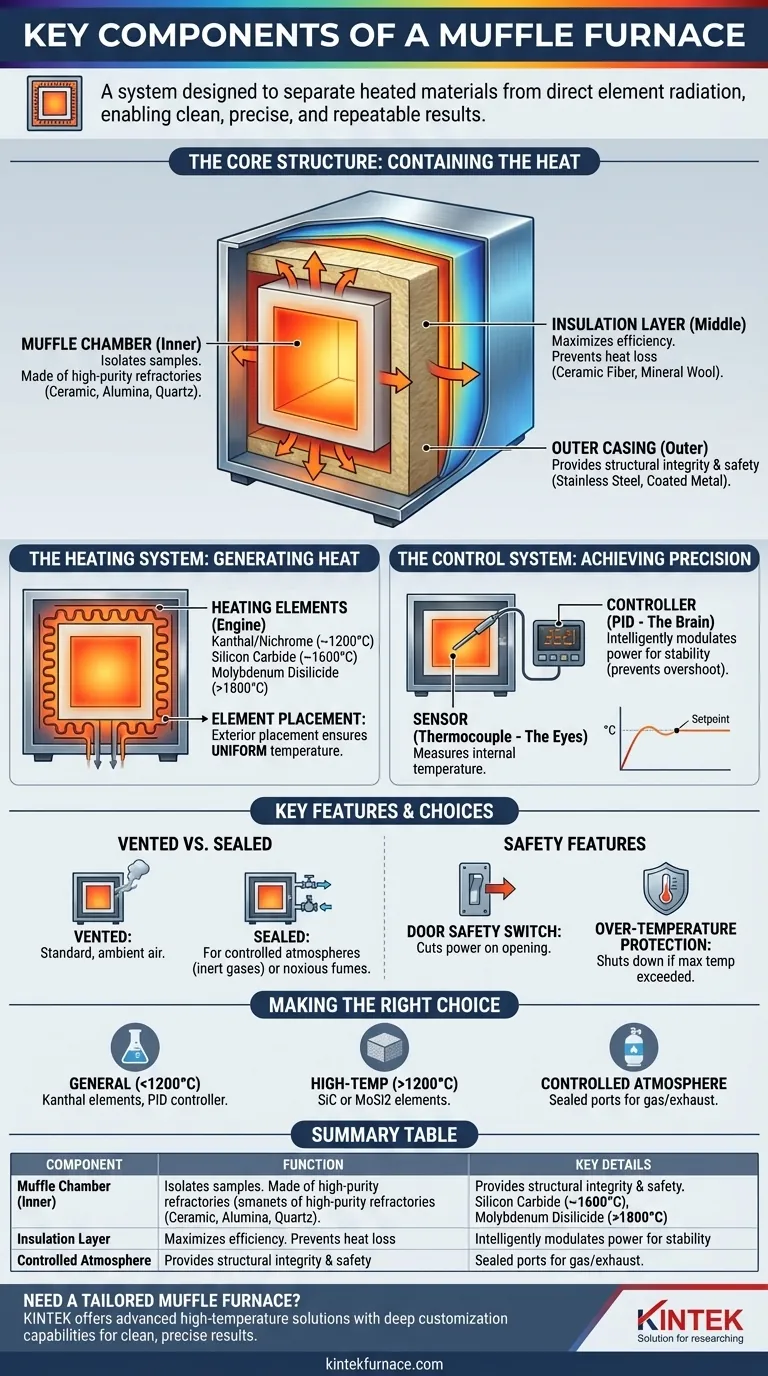

At its core, a muffle furnace is a system built from five key components: an insulated inner chamber (the muffle), heating elements, a temperature control system, a layer of thermal insulation, and a protective outer casing. These parts work in unison to provide a highly controlled, uniform, and isolated high-temperature environment for laboratory and industrial processes.

The critical insight is not just knowing the parts, but understanding that a muffle furnace is designed to separate the material being heated from the direct radiation and potential contamination of the heating elements themselves. This separation, or "muffling," is what enables clean, precise, and repeatable results.

The Core Structure: Containing the Heat

The physical body of the furnace is a layered system designed for thermal containment, efficiency, and structural integrity. Each layer serves a distinct purpose.

The Muffle Chamber: The Heart of the Furnace

This is the inner chamber where samples are placed. It is made from high-purity, chemically inert refractory materials like dense ceramic, alumina, or quartz.

Its primary job is to isolate the sample from the heating elements. This prevents any gases or particles shed by the elements at extreme temperatures from contaminating the sample, which is crucial for applications like ash testing or elemental analysis.

The Insulation Layer: Maximizing Thermal Efficiency

Surrounding the muffle chamber is a thick layer of insulation, typically made from ceramic fiber or mineral wool.

This layer is critical for preventing heat from escaping into the lab. It dramatically improves the furnace's energy efficiency, allows for faster heat-up times, and ensures the outer surface remains at a safe temperature for operators.

The Outer Casing: Providing Structural Integrity

The outermost layer is a rigid shell, usually constructed from stainless steel or powder-coated metal. It provides structural support for all the internal components and protects them from the external environment.

The Heating System: Generating and Delivering Heat

The furnace's ability to reach and maintain high temperatures is governed by its heating elements and how they are controlled.

Heating Elements: The Engine of the Furnace

These are high-resistance components that generate intense heat when a strong electric current is passed through them.

The material used for the heating element determines the furnace's maximum operating temperature. Common materials include:

- Kanthal (FeCrAl) or Nichrome (NiCr): For temperatures up to ~1200°C.

- Silicon Carbide (SiC): For temperatures up to ~1600°C.

- Molybdenum Disilicide (MoSi2): For the highest temperatures, often exceeding 1800°C.

Element Placement: The Key to Uniformity

Crucially, the heating elements are placed around the exterior of the muffle chamber, not inside it. This arrangement ensures that heat radiates inward evenly from multiple sides, providing uniform temperature throughout the entire chamber.

The Control System: Achieving Precision

A muffle furnace is useless without a system to precisely regulate its temperature. This is the job of the sensor and the controller.

The Sensor (Thermocouple): The Eyes of the System

A thermocouple is a sensor placed inside the heating chamber (often near the back) to get an accurate reading of the internal temperature. It continuously measures the heat and sends this data back to the controller as an electrical signal.

The Controller (PID): The Brain of the Operation

The temperature controller is the furnace's brain. Modern furnaces use a PID (Proportional-Integral-Derivative) controller, which is far more sophisticated than a simple thermostat.

Instead of just turning the heat on or off, a PID controller intelligently modulates the power sent to the heating elements. It anticipates temperature changes, preventing overshoot and maintaining the setpoint with exceptional stability, often within a single degree.

Understanding the Trade-offs and Key Features

Not all muffle furnaces are the same. Understanding the differences is key to choosing the right tool for your specific task.

Vented vs. Sealed Chambers

Most standard furnaces are vented to the ambient air. However, some processes release noxious fumes or require a specific atmosphere. For this, furnaces can include exhaust ports to safely vent fumes or air intake ports to introduce inert gases like nitrogen or argon.

Critical Safety Features

Safety mechanisms are non-negotiable components. A door safety switch immediately cuts power to the heating elements when the door is opened, protecting the user from extreme heat and electrical hazards. Over-temperature protection is a separate circuit that shuts the furnace down if it exceeds a maximum safe temperature, preventing catastrophic failure.

Material Limitations

The choice of muffle and heating element material dictates the furnace's limits. Using a furnace above its rated temperature can cause permanent damage to the elements, while certain chemical vapors can degrade the muffle material over time.

Making the Right Choice for Your Goal

Selecting the correct furnace configuration depends entirely on your intended application.

- If your primary focus is general ashing, moisture determination, or heat-treating below 1200°C: A standard furnace with Kanthal elements and a reliable PID controller is the ideal workhorse.

- If your primary focus is high-temperature materials science or ceramics work (above 1200°C): You must invest in a furnace with specialized Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2) heating elements.

- If your primary focus is working with reactive materials or requiring controlled atmospheres: A furnace equipped with sealed gas intake and exhaust ports is essential for procedural integrity and safety.

Understanding how these components function as a system empowers you to select and operate the right tool for precise and repeatable high-temperature work.

Summary Table:

| Component | Function | Key Details |

|---|---|---|

| Muffle Chamber | Isolates samples from contamination | Made from refractory materials like alumina or quartz |

| Heating Elements | Generates heat for high temperatures | Materials: Kanthal (up to 1200°C), SiC (up to 1600°C), MoSi2 (over 1800°C) |

| Temperature Control System | Regulates temperature precisely | Uses PID controller and thermocouple for stability |

| Insulation Layer | Prevents heat loss and improves efficiency | Made from ceramic fiber or mineral wool |

| Outer Casing | Provides structural support and safety | Constructed from stainless steel or coated metal |

Need a muffle furnace tailored to your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your experimental requirements. Whether you're in materials science, ceramics, or general lab work, we ensure clean, precise, and repeatable results. Contact us today to discuss how we can enhance your high-temperature processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization