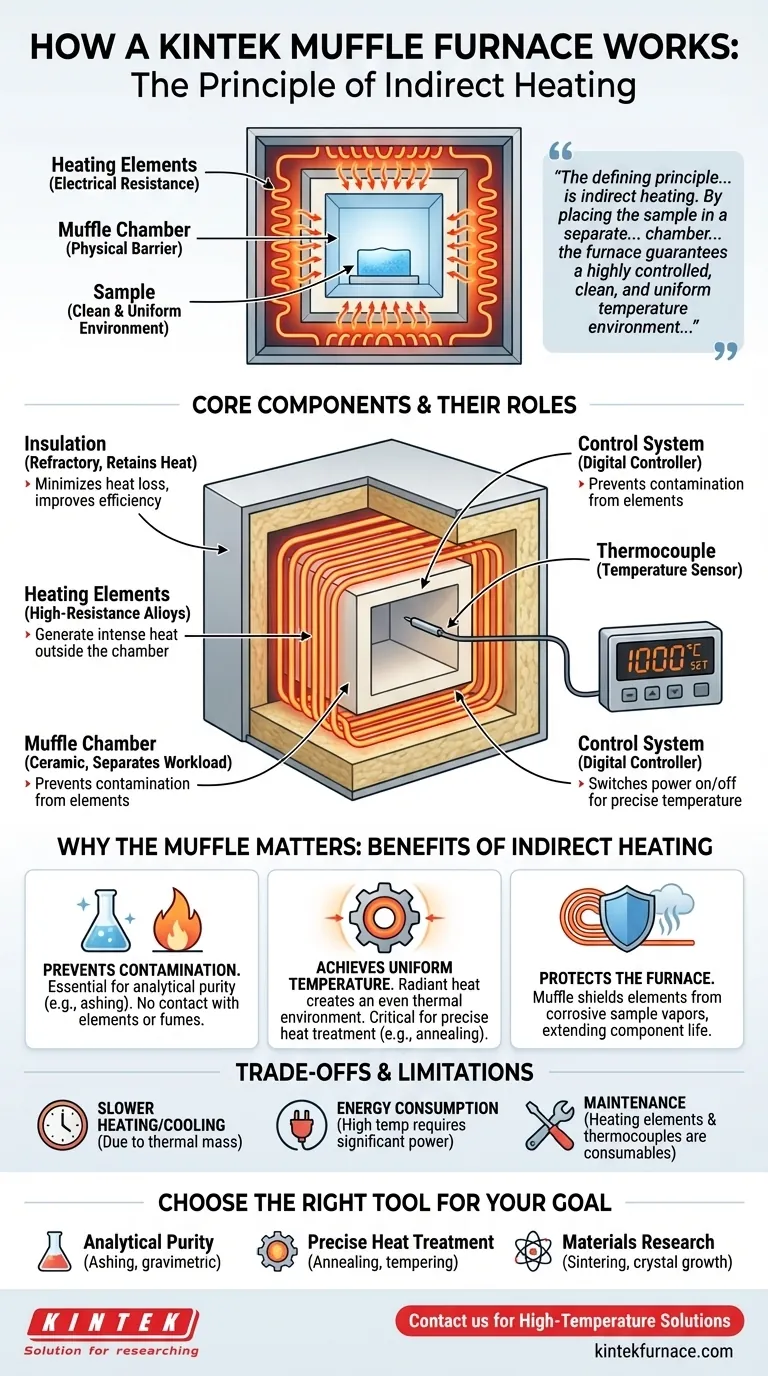

At its core, a muffle furnace operates by using electrical heating elements to heat an insulated chamber from the outside. The "muffle" is this internal chamber, which separates the material being heated from the raw heating elements. This design ensures the sample is heated indirectly and uniformly, without any risk of contamination from the heat source itself.

The defining principle of a muffle furnace is indirect heating. By placing the sample in a separate, enclosed chamber (the muffle), the furnace guarantees a highly controlled, clean, and uniform temperature environment, which is essential for sensitive scientific and industrial processes.

Deconstructing the Furnace: Core Components and Their Roles

To truly understand how a muffle furnace works, you must understand its four critical components and how they interact to achieve high, stable temperatures.

The Heating Elements: The Engine of Heat

The heat is generated through electrical resistance. Electricity is passed through specialized heating coils, typically made of high-resistance alloys like Kanthal (iron-chromium-aluminum) or Nichrome (nickel-chromium). As electricity struggles to pass through these materials, it generates intense heat.

These elements are strategically placed around the outside of the central chamber.

The Muffle Chamber: The Heart of the Process

The muffle is the enclosed, box-like chamber where you place your sample or workpiece. It is made from high-temperature, heat-resistant ceramic materials.

Its primary purpose is to act as a physical barrier. It separates the workload from the heating elements, creating a clean environment free from any potential contaminants that might be shed from the coils at extreme temperatures.

The Insulation: Retaining the Heat

To reach and maintain temperatures that can exceed 1000°C (1800°F), a muffle furnace must be exceptionally well-insulated.

The muffle and heating elements are encased in layers of refractory insulation, such as ceramic fiber blankets or dense refractory bricks. This insulation minimizes heat loss, which improves temperature stability and energy efficiency.

The Control System: Ensuring Precision

A muffle furnace is useless without precise control. A thermocouple (a temperature sensor) is placed inside the chamber to constantly measure the internal temperature.

This sensor feeds data to a digital controller. The controller then switches the power to the heating elements on and off to maintain the exact temperature setpoint you have programmed, ensuring the process is both accurate and repeatable.

The Principle of Indirect Heating: Why the Muffle Matters

The use of a separate muffle chamber is not an arbitrary design choice; it is the key to the furnace's unique capabilities and is essential for high-stakes applications.

Preventing Sample Contamination

For analytical work like ashing (burning off organic material to measure inorganic content) or materials analysis, sample purity is paramount. The muffle ensures that no part of the heating element or external atmosphere can contaminate the sample, guaranteeing accurate results.

In older or specialized fuel-fired models, the muffle was even more critical, as it protected the sample from the direct flame and byproducts of combustion.

Achieving Uniform Temperature

Because the heating elements warm the walls of the muffle chamber, the heat then radiates inward evenly from all sides. This creates a highly uniform thermal environment with minimal hot or cold spots.

This even heating is critical for processes like annealing or tempering metals, where precise temperature control across the entire part is necessary to achieve the desired material properties.

Protecting the Furnace Itself

The barrier works both ways. The muffle also protects the delicate heating elements from any corrosive fumes, vapors, or spatters that might be released from the sample during heating. This separation extends the life of the heating elements.

Understanding the Trade-offs and Limitations

While powerful, the muffle furnace design comes with inherent trade-offs that are important to recognize.

Heating and Cooling Speed

Because heat must first saturate the muffle chamber walls before radiating to the sample, these furnaces generally have slower heating rates compared to direct heating methods (like an induction furnace). They also retain heat for a long time, leading to slow cooling cycles.

Energy Consumption

Achieving and maintaining very high temperatures is an energy-intensive process. The excellent insulation retains heat well, but the initial ramp-up to temperature and long soak times can result in significant electrical consumption.

Maintenance and Component Lifespan

The components that operate at extreme temperatures, primarily the heating elements and the thermocouple, are consumables. Over hundreds or thousands of hours of use, they will degrade and eventually require replacement.

Making the Right Choice for Your Goal

Understanding the principle of indirect heating allows you to determine when a muffle furnace is the correct tool for the job.

- If your primary focus is analytical purity (e.g., ashing, gravimetric analysis): The muffle's separation is non-negotiable to prevent sample contamination and ensure accurate measurements.

- If your primary focus is precise heat treatment (e.g., annealing, tempering): The uniform, controlled heating of a muffle furnace ensures consistent and repeatable material properties across the entire workpiece.

- If your primary focus is materials research (e.g., sintering ceramics, crystal growth): The furnace provides the stable, clean, and repeatable high-temperature environment that is critical for developing and testing new materials.

Ultimately, the muffle furnace's design prioritizes a controlled, clean, and uniform heating environment over raw speed, making it an indispensable tool for precision work.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Heating Elements | Generate heat via electrical resistance | Provides the energy source for high temperatures |

| Muffle Chamber | Encloses the sample, separating it from heating elements | Prevents contamination and ensures clean heating |

| Insulation | Encases the chamber to minimize heat loss | Improves temperature stability and energy efficiency |

| Control System | Uses a thermocouple and digital controller | Maintains precise, repeatable temperature setpoints |

Need a High-Temperature Furnace for Your Precision Work?

KINTEK's advanced muffle furnaces are engineered to deliver the clean, uniform, and controlled heating environment your sensitive processes demand. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust solutions, including Muffle, Tube, and Vacuum Furnaces.

Our strong deep customization capability allows us to precisely tailor a furnace to your unique experimental requirements.

Contact us today to discuss how we can enhance your lab's capabilities with a reliable high-temperature solution!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating