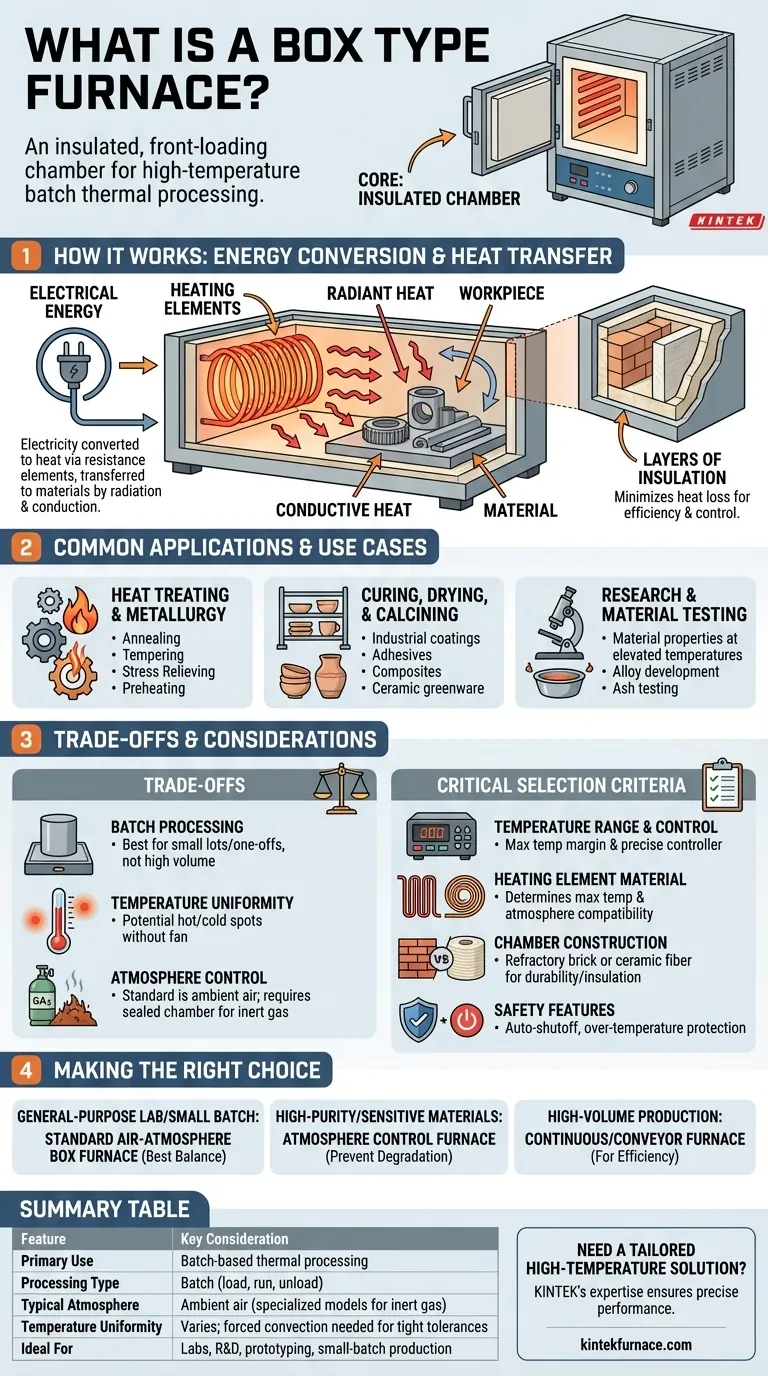

At its core, a box furnace is an insulated, front-loading chamber used for high-temperature thermal processing. Characterized by a simple box-like shape with either a swing-out or vertical-lift door, it functions by converting electrical energy into heat. This heat is then transferred to the materials inside through conduction and radiation to perform tasks like annealing, curing, or stress relieving.

A box furnace is a fundamental tool for batch-based thermal processing. Its value lies not in complexity, but in its versatility for a wide range of applications where a controlled, high-temperature environment is required for a single part or a group of parts at a time.

The Fundamental Operating Principle

A box furnace operates on simple, reliable principles of energy conversion and heat transfer. Understanding this foundation is key to using the equipment effectively.

From Electricity to Heat

The process begins with electrical heating elements, typically made of high-resistance alloys or ceramic composites, mounted along the furnace's interior walls. When a high electrical current is passed through them, their resistance causes them to heat up intensely, glowing red or white-hot and releasing thermal energy into the chamber.

Heat Transfer Within the Chamber

This thermal energy heats the materials placed inside the furnace through two primary methods. Radiation from the hot elements travels through the space and is absorbed by the material's surface, while conduction occurs as the ambient hot air and the furnace hearth transfer heat directly to the material upon contact.

The Role of the Insulated Box

The "box" itself is a critical component. It is constructed with layers of high-temperature insulation, such as refractory bricks or ceramic fiber, to minimize heat loss. This ensures thermal efficiency and allows the furnace to reach and maintain very high temperatures in a stable, controlled environment.

Common Applications and Use Cases

The versatility of the box furnace makes it a staple in laboratories, prototyping shops, and small-scale production facilities across many industries.

Heat Treating and Metallurgy

This is a primary application. Processes like annealing (softening metals), tempering (increasing toughness), stress relieving (removing internal stresses from welding or machining), and preheating parts for forging or welding are all common tasks for a box furnace.

Curing, Drying, and Calcining

Box furnaces are widely used for curing industrial coatings, adhesives, and composites. They are also essential for drying ceramic greenware before firing or calcining materials to induce a phase change through high heat.

Research and Material Testing

In R&D settings, box furnaces provide a controlled thermal environment for testing material properties at elevated temperatures, developing new alloys, or performing ash testing on samples.

Understanding the Trade-offs

While versatile, the box furnace design has inherent limitations. Objectively weighing these against your needs is critical for proper selection.

Batch Processing vs. Continuous Flow

The defining characteristic of a box furnace is its use for batch processing. You load a part or a group of parts, run the thermal cycle, and then unload them. This is ideal for one-off jobs or small lots but is inefficient for high-volume manufacturing, where a continuous conveyor furnace would be superior.

Temperature Uniformity

Achieving perfect temperature uniformity can be a challenge. Without a fan to circulate the air, static "hot spots" can develop near the heating elements, while "cold spots" may exist elsewhere. For processes requiring extremely tight temperature tolerances, a furnace with a forced convection fan is necessary.

Atmosphere Control

A standard box furnace operates in ambient air. This is unsuitable for materials that oxidize (rust) or react with air at high temperatures. While specialized box furnaces with sealed chambers and ports for inert gas (like Argon or Nitrogen) exist, they represent a significant increase in complexity and cost.

Critical Selection Criteria

Choosing the right furnace requires matching its specifications to your exact process requirements.

Temperature Range and Control

Ensure the furnace's maximum operating temperature provides a safe margin above your process needs. Equally important is the temperature controller, which dictates the precision and repeatability of your heating and cooling profiles.

Heating Element Material

The type of heating element determines the furnace's maximum temperature and its compatibility with different atmospheres. Common materials have different temperature ceilings and lifespans.

Chamber Construction

The furnace's internal lining—whether hard refractory brick or lightweight ceramic fiber—impacts its durability, heating/cooling rates, and resistance to chemical wear. The choice depends on the intended application and the materials being processed.

Safety Features

Look for critical safety systems like automatic shutoff for door opening, over-temperature protection to prevent runaway heating, and proper electrical certifications. These are non-negotiable for protecting both personnel and the equipment itself.

Making the Right Choice for Your Application

Use your core objective to guide your decision.

- If your primary focus is general-purpose lab work or varied, small-batch tasks: A standard air-atmosphere box furnace offers the best balance of versatility and cost.

- If your primary focus is high-purity metal processing or oxygen-sensitive materials: You must invest in a furnace with atmosphere control capabilities to prevent material degradation.

- If your primary focus is high-volume production of identical parts: The batch nature of a box furnace will be a bottleneck; a continuous or conveyor-style furnace is the correct tool.

Ultimately, selecting the right furnace is about clearly defining your thermal processing needs before evaluating the equipment.

Summary Table:

| Feature | Key Consideration |

|---|---|

| Primary Use | Batch-based thermal processing (annealing, curing, stress relieving) |

| Processing Type | Batch processing (load, run cycle, unload) |

| Typical Atmosphere | Ambient air (specialized models available for inert gas) |

| Temperature Uniformity | Can vary; forced convection models needed for tight tolerances |

| Ideal For | Labs, R&D, prototyping, and small-batch production |

Need a high-temperature furnace tailored to your specific process?

KINTEK's expertise in advanced thermal solutions ensures your lab gets the precise performance it needs. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust box furnaces, alongside Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, from material selection to chamber design.

Contact KINTEL today to discuss how we can engineer the ideal high-temperature solution for your application.

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- Why is a laboratory high-temperature box furnace essential for KNN ceramic powders? Mastering Solid-State Synthesis

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate