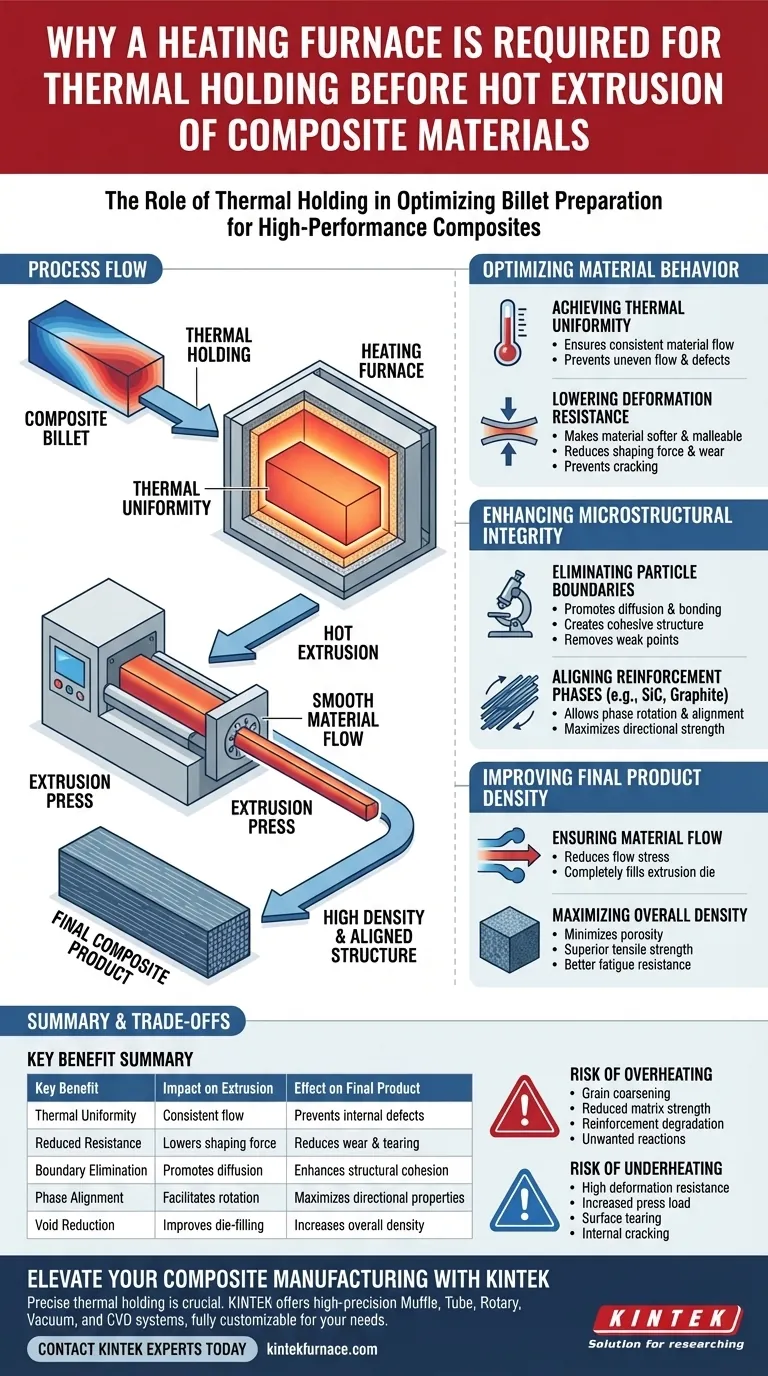

Thermal holding plays a pivotal role in preparing composite billets for the intense physical stress of hot extrusion. By utilizing a heating furnace to maintain a specific temperature, you ensure the material achieves thermal uniformity, which significantly lowers its resistance to deformation and guarantees smooth flow during the extrusion process.

The primary purpose of thermal holding is to homogenize the material's temperature, thereby reducing deformation resistance and optimizing microstructural alignment. This pre-processing step is essential for achieving high density and eliminating particle boundaries in the final composite product.

Optimizing Material Behavior

Achieving Thermal Uniformity

The core function of the heating furnace is to bring the entire billet to a consistent, specific temperature.

Without this uniformity, temperature gradients within the material would lead to uneven flow, causing defects in the final product.

Lowering Deformation Resistance

When the composite is held at the correct elevated temperature, the material becomes softer and more malleable.

This lowers the force required to shape the material, reducing wear on the extrusion equipment and preventing the billet from cracking under pressure.

Enhancing Microstructural Integrity

Eliminating Particle Boundaries

Thermal holding promotes diffusion and bonding between the constituent particles of the composite.

This process helps eliminate distinct particle boundaries, which are often the weakest points in a composite material. Removing these boundaries creates a more cohesive and continuous structure.

Aligning Reinforcement Phases

The combination of heat and the subsequent extrusion flow has a specific effect on reinforcements, such as Silicon Carbide (SiC) and graphite.

Proper thermal holding allows these phases to rotate and align along the extrusion direction. This directional alignment is critical for maximizing the mechanical strength of the composite along the axis of use.

Improving Final Product Density

Ensuring Material Flow

The reduction in flow stress allows the material to fill the extrusion die completely.

This ensures that internal voids are closed and that the material consolidates effectively during the process.

Maximizing Overall Density

By combining uniform heat with the pressure of extrusion, the porosity of the material is minimized.

A higher overall density directly correlates to superior mechanical properties, such as tensile strength and fatigue resistance.

Understanding the Trade-offs

The Risk of Overheating

While heating is essential, exceeding the optimal temperature or holding the material for too long can be detrimental.

Excessive heat may cause grain coarsening, which reduces the strength of the matrix material. It can also degrade certain reinforcement phases or cause unwanted chemical reactions at the interface between the matrix and the reinforcement.

The Risk of Underheating

Conversely, failing to reach the target temperature results in high deformation resistance.

This increases the load on the extrusion press and raises the likelihood of surface tearing or internal cracking due to poor material flow.

Ensuring Extrusion Success

To maximize the quality of your composite materials, you must tailor the thermal holding parameters to your specific performance targets.

- If your primary focus is Structural Integrity: Prioritize a holding time that ensures complete thermal saturation to fully eliminate particle boundaries.

- If your primary focus is Directional Strength: precise temperature control is vital to facilitate the flow required to align reinforcements like SiC and graphite without degrading them.

By strictly controlling the thermal holding environment, you transform a raw billet into a high-performance composite ready for demanding applications.

Summary Table:

| Key Benefit | Impact on Extrusion Process | Effect on Final Product |

|---|---|---|

| Thermal Uniformity | Ensures consistent material flow | Prevents internal defects and cracks |

| Reduced Resistance | Lowers the force required for shaping | Reduces equipment wear and surface tearing |

| Boundary Elimination | Promotes particle diffusion/bonding | Enhances structural cohesion and strength |

| Phase Alignment | Facilitates rotation of reinforcements | Maximizes directional mechanical properties |

| Void Reduction | Improves die-filling capability | Increases overall density and fatigue resistance |

Elevate Your Composite Manufacturing with KINTEK

Precise thermal holding is the difference between a failed extrusion and a high-performance composite. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all fully customizable to meet your unique material parameters.

Don't let temperature gradients compromise your material's integrity. Ensure perfect thermal saturation and microstructural alignment with our industry-leading heating solutions.

Contact KINTEK Experts Today to Discuss Your Custom Furnace Needs

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a double-chamber device preferred over a standard electric furnace for sintering? Achieve Oxidation-Free Results

- Why is a muffle furnace utilized for primary heat treatment at 250 °C? Optimize Your Perovskite Catalyst Structure

- Why is a high-precision muffle furnace required for TiCo1-xCrxSb? Achieve Perfect Phase Purity

- What core roles does a muffle furnace play in the crystal growth of NaNbO3:Pr3+? Enhance Your Material Synthesis

- What are the primary applications of a laboratory muffle furnace? Achieve Precise, Contaminant-Free High-Temperature Processing

- What restrictions apply to materials placed in the muffle furnace? Ensure Safe, High-Temperature Processing

- What role does a high-temperature sintering furnace play in TiO2 layers? Achieve Superior Solar Cell Performance

- Why is the muffle furnace heat treatment necessary for NiCo2O4/ZnO-CuO/NF electrodes? Unlock High-Performance Activity