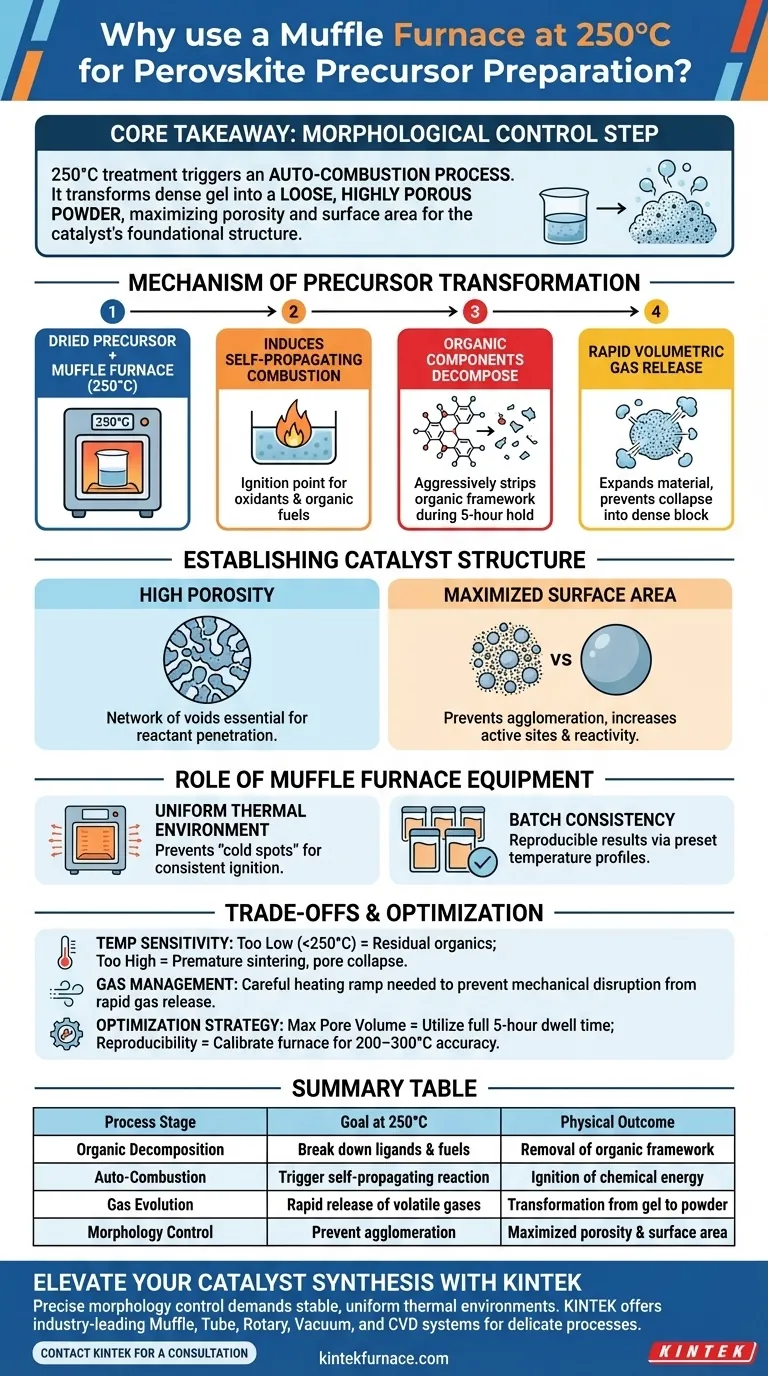

A muffle furnace is utilized at 250 °C primarily to induce a self-propagating combustion reaction within the dried precursor gel. This specific thermal treatment decomposes organic components, resulting in the rapid release of a large volume of gas. The expanding gas transforms the dense gel into a loose, highly porous powder, which is the foundational structure required for an effective perovskite catalyst.

Core Takeaway: The 250 °C treatment is not merely for drying; it is a morphological control step. It triggers an auto-combustion process that maximizes porosity and surface area, defining the catalyst's potential reactivity before final sintering.

The Mechanism of Precursor Transformation

Inducing Self-Propagating Combustion

The primary function of the muffle furnace at this stage is to provide a stable medium-temperature environment (250 °C). This temperature acts as the ignition point for the oxidants and organic fuels within the dried gel.

Once the threshold is reached, the reaction becomes self-propagating. It moves through the material on its own energy, requiring the furnace only to maintain the ambient condition rather than driving the reaction kinetics directly.

Decomposition of Organic Components

During the five-hour hold time at 250 °C, the organic ligands and components inside the gel break down thermally. This decomposition is aggressive and effectively strips the organic framework away from the metal ions.

Volumetric Gas Release

As the organics decompose, they convert into gases. Because this happens rapidly within the gel structure, the escaping gas forces the material to expand. This expansion prevents the material from collapsing into a dense block.

Establishing Catalyst Structure

Creation of High Porosity

The most critical outcome of this process is the physical texture of the resulting powder. The "explosive" release of gas leaves behind a network of voids and pores.

This porous network is essential for the catalyst's function. It ensures that reactant gases or liquids can penetrate deep into the material rather than just interacting with the outer shell.

Maximizing Reaction Surface Area

The transition from a gel to a loose precursor powder drastically increases the specific surface area. By preventing agglomeration at this early stage, the process ensures that more active sites are exposed.

A higher surface area directly correlates to higher catalytic efficiency in the final application.

The Role of the Muffle Furnace Equipment

Uniform Thermal Environment

While the chemical reaction drives the porosity, the muffle furnace ensures the trigger temperature is applied evenly. Its enclosed design prevents thermal gradients that could lead to "cold spots" where the reaction fails to ignite.

Batch Consistency

The stability of the laboratory muffle furnace allows for reproducible results. By adhering to a preset temperature curve, the furnace ensures that every batch of precursor undergoes the exact same decomposition profile.

Understanding the Trade-offs

Temperature Sensitivity

While 250 °C is the target for this specific precursor, deviation can be detrimental. If the temperature is too low, the auto-combustion will not trigger, leaving residual organics that contaminate the final product. Conversely, excessive temperatures (e.g., uncontrolled spikes) could induce premature sintering, collapsing the pores you are trying to create.

Management of Gas Evolution

The rapid release of gas is beneficial for porosity but requires careful management. The sudden expansion can mechanically disrupt the container or scatter the powder if the heating ramp is too aggressive before the 250 °C dwell time.

Optimizing Your Heat Treatment Strategy

To ensure the highest quality perovskite catalyst, tailor your approach based on your specific structural goals:

- If your primary focus is maximizing pore volume: Ensure the temperature dwell time is fully utilized (5 hours) to allow complete gas evolution throughout the entire bulk of the gel.

- If your primary focus is batch-to-batch reproducibility: Calibrate the muffle furnace specifically for the 200–300 °C range, as some high-temp furnaces may fluctuate more at these lower "medium" settings.

The success of your catalyst relies not just on the chemistry of the gel, but on the precision of the thermal environment that creates its skeleton.

Summary Table:

| Process Stage | Goal at 250 °C | Physical Outcome |

|---|---|---|

| Organic Decomposition | Break down ligands & fuels | Removal of organic framework |

| Auto-Combustion | Trigger self-propagating reaction | Ignition of chemical energy |

| Gas Evolution | Rapid release of volatile gases | Transformation from gel to powder |

| Morphology Control | Prevent agglomeration | Maximized porosity & surface area |

Elevate Your Catalyst Synthesis with KINTEK

Precise morphology control in perovskite preparation demands a uniform thermal environment and absolute temperature stability. KINTEK provides industry-leading heating solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—specifically engineered to handle delicate processes like auto-combustion and organic decomposition.

Backed by expert R&D and precision manufacturing, our lab high-temp furnaces are fully customizable to meet your unique research or production needs. Ensure batch-to-batch consistency and maximize your catalyst's reactive surface area today.

Contact KINTEK for a Professional Consultation

Visual Guide

References

- Li Yang, Zongping Shao. Rational Design of a Perovskite‐Type Catalyst for Toluene Oxidation Via Simultaneous Phosphorus Doping and Post‐Synthesis Acidic Etching. DOI: 10.1002/eem2.70115

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the primary uses of a box furnace? Unlock Precise Heat Treatment for Your Materials

- What are the specific applications of box type electric furnaces in metallurgy? Essential for Heat Treatment and Material Synthesis

- What are some general-purpose uses of muffle furnaces? Essential for Clean, High-Temperature Processing

- How does a muffle furnace work in terms of heating principle? Discover Indirect Heating for Pure, Uniform Results

- What is the primary function of an electric muffle furnace? Ensure Purity and Uniform Heating

- How can the front panel of the box furnace be configured? Optimize Temperature Control for Your Lab

- Why is a precision muffle furnace used for gradient heating during the synthesis of doped Tungsten Diselenide (WSe2)?

- What role does a muffle furnace play in Fe-TiO2 catalyst activation? Achieve Precise Phase Transformation