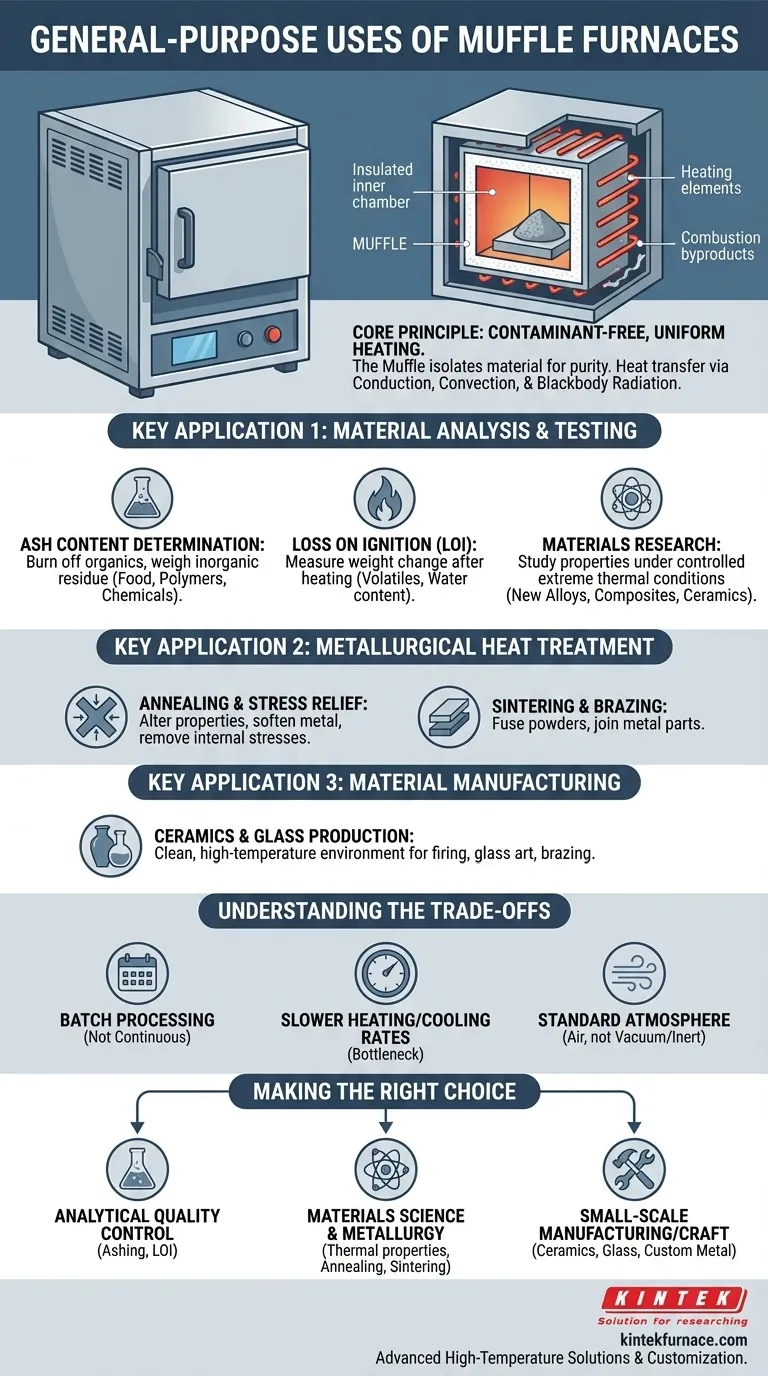

In essence, a muffle furnace is a high-temperature oven used for general-purpose applications that require clean, uniform heating. Its most common uses across laboratories and industries fall into three main categories: performing material analysis like ashing, executing heat treatments to alter metallurgical properties, and manufacturing materials like ceramics and glass.

The core value of a muffle furnace is its ability to heat a sample to very high temperatures without contamination. The "muffle" isolates the material from the heating elements and any combustion byproducts, ensuring the process atmosphere is pure and controlled.

The Core Principle: Contaminant-Free Heating

A muffle furnace's versatility stems from one simple but critical design feature that separates it from a standard oven or kiln.

What is a "Muffle"?

The term "muffle" refers to the insulated inner chamber that contains the sample. This chamber separates, or "muffles," the material being heated from the actual heat source (electric coils or gas flames).

This design eliminates contamination from combustion byproducts like soot or gases that would otherwise alter the sample's chemistry. This makes it an ideal tool for precise analytical work and sensitive material processing.

How It Achieves Uniform Heat

Modern electrical muffle furnaces do not rely on a single, direct heat source. Instead, they heat the chamber's interior walls to a uniform temperature.

The heat is then transferred to the sample through a combination of conduction, convection, and blackbody radiation. This multi-faceted approach ensures a highly consistent temperature throughout the chamber, critical for reliable and repeatable results.

Key Application 1: Material Analysis and Testing

The muffle furnace is a workhorse in analytical chemistry and quality control labs, primarily for preparing and testing samples at high temperatures.

Ash Content Determination

This is one of the most common applications. The furnace is used for ashing, a process that involves heating a sample to burn off all organic substances.

The inorganic residue that remains, known as ash, can then be weighed and analyzed to determine its percentage in the original sample. This is a standard quality test in the food, polymer, and chemical industries.

Loss on Ignition (LOI)

Closely related to ashing, Loss on Ignition analysis measures the change in a sample's weight after it has been heated to a high temperature. This is used to determine the content of volatile materials or water.

Materials Research

Researchers use muffle furnaces to subject materials to controlled, extreme thermal conditions. This allows them to study how properties like strength, conductivity, or crystal structure change with heat, advancing the development of new alloys, composites, and ceramics.

Key Application 2: Metallurgical Heat Treatment

In metallurgy and material science, heat is used to intentionally change a metal's physical and mechanical properties.

Annealing, Drawing, and Stress Relief

These processes involve heating a metal to a specific temperature and then cooling it slowly. Annealing makes a metal softer and more ductile, making it easier to work with. Stress relief removes internal stresses created during manufacturing processes like welding or machining.

Sintering and Brazing

Sintering is a process where powdered materials (metal or ceramic) are heated to just below their melting point, causing the particles to fuse together into a solid piece.

Brazing is a metal-joining process where a filler metal is melted to flow into the gap between two closely fitted parts, bonding them upon cooling.

Understanding the Trade-offs

While extremely versatile, a muffle furnace is not always the optimal tool. Understanding its limitations is key to using it effectively.

Batch Processing vs. Continuous Flow

Muffle furnaces are batch processors. You load a sample, run a heating cycle, and then unload it. This is ideal for lab-scale work or unique parts but is inefficient for high-volume, continuous manufacturing.

Heating and Cooling Rates

Due to their heavy insulation, muffle furnaces can take a significant amount of time to heat up and cool down. This can be a bottleneck in a high-throughput environment. Specialized furnaces may offer faster thermal cycling when required.

Atmosphere Control

A standard muffle furnace operates in air. While this is suitable for many applications, processes requiring a specific atmosphere (like a vacuum or an inert gas like argon) necessitate a more specialized and expensive type of furnace.

Making the Right Choice for Your Goal

To determine if a general-purpose muffle furnace fits your needs, consider your primary objective.

- If your primary focus is analytical quality control: Its ability to perform clean and complete ashing or Loss on Ignition makes it an indispensable tool for sample preparation.

- If your primary focus is materials science or metallurgy: It is the standard apparatus for testing thermal properties and performing fundamental heat treatments like annealing and sintering.

- If your primary focus is small-scale manufacturing or craft: The furnace provides the precise, high-temperature environment needed for firing ceramics, creating glass art, or brazing custom metal components.

Ultimately, the muffle furnace is a foundational piece of equipment that provides clean, high, and uniform heat for an exceptionally wide range of applications.

Summary Table:

| Application Category | Key Uses | Benefits |

|---|---|---|

| Material Analysis | Ashing, Loss on Ignition, Materials Research | Contaminant-free heating, precise temperature control |

| Metallurgical Heat Treatment | Annealing, Sintering, Brazing | Alters material properties, uniform heating |

| Material Manufacturing | Ceramics, Glass Production | Clean, high-temperature environment for fabrication |

Ready to enhance your lab's capabilities with a custom muffle furnace? KINTEK specializes in advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring precise, contaminant-free heating for applications like ashing, heat treatment, and material production. Contact us today to discuss how we can optimize your processes and deliver reliable performance tailored to your goals!

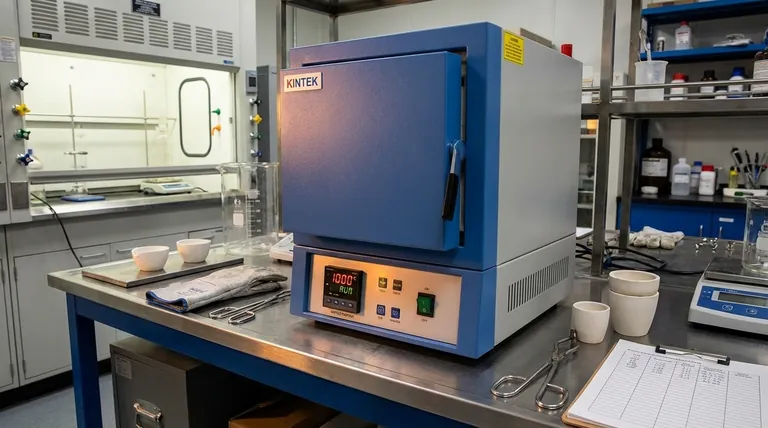

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency