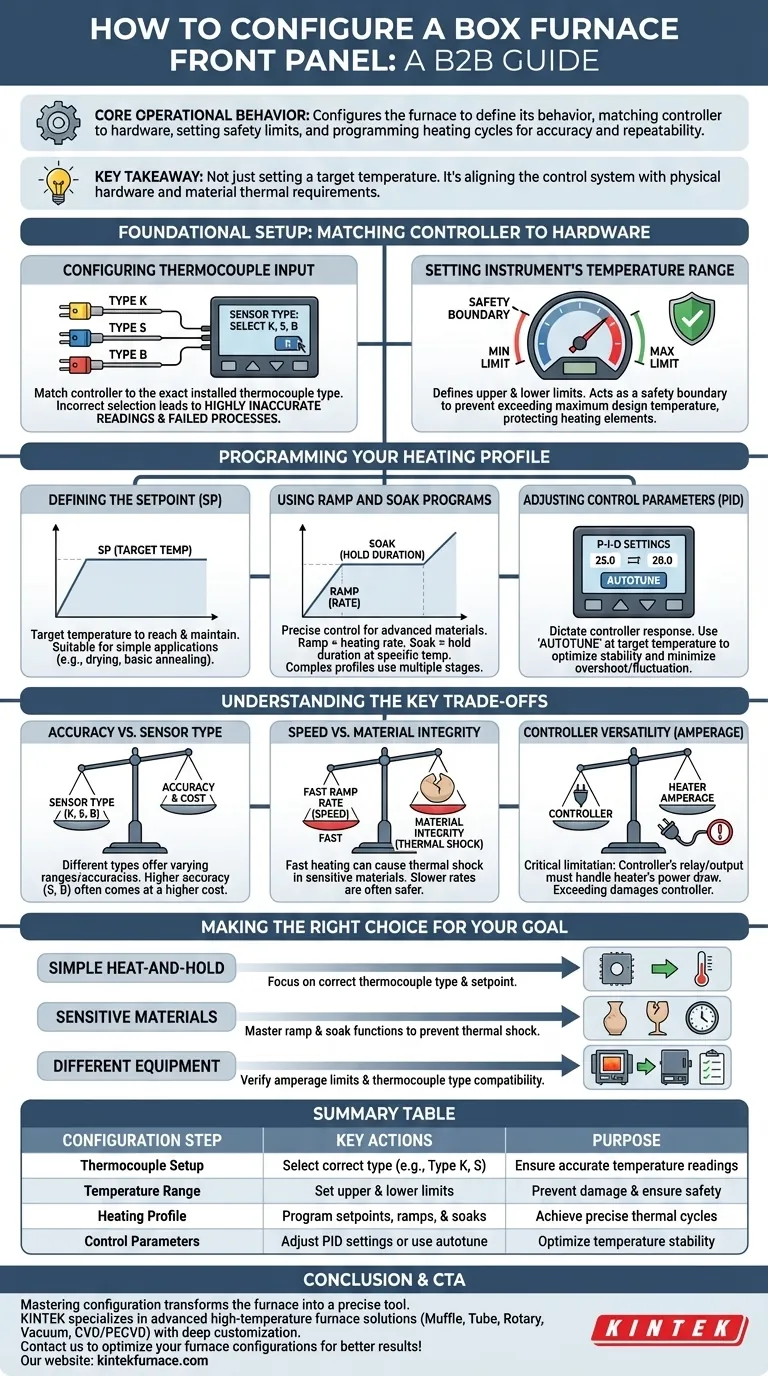

In short, the front panel of a box furnace is configured to define its core operational behavior. This involves setting the type of temperature sensor (thermocouple) being used, defining the allowable temperature range for the instrument, and programming the specific heating cycles required for your process. These settings ensure the furnace operates accurately, safely, and is matched to the needs of your application.

Configuring the furnace's front panel is not just about setting a target temperature. It is a critical process of aligning the control system with both the physical hardware (like the thermocouple) and the specific thermal requirements of your material to ensure accurate and repeatable results.

Foundational Setup: Matching Controller to Hardware

Before you can program a heating cycle, you must first tell the controller about the physical system it is managing. This foundational setup ensures the temperature it thinks it is reading is the actual temperature inside the furnace.

Configuring the Thermocouple Input

A thermocouple is the sensor that measures the furnace's internal temperature. Different types of thermocouples (e.g., Type K, Type S, Type B) produce different voltage signals at the same temperature.

You must configure the controller to match the exact type of thermocouple installed. Selecting the wrong type will cause the controller to misinterpret the voltage signal, leading to highly inaccurate temperature readings and failed processes.

Setting the Instrument's Temperature Range

This configuration defines the upper and lower temperature limits for the controller itself. It acts as a safety and operational boundary.

Setting this range prevents users from accidentally programming a setpoint that exceeds the furnace's maximum design temperature, protecting both the heating elements and the furnace structure.

Programming Your Heating Profile

Once the foundational setup is complete, you can program the specific thermal cycle your material requires. This can range from a simple heat-and-hold to a complex multi-stage process.

Defining the Setpoint (SP)

The setpoint is the target temperature you want the furnace to reach and maintain. For simple applications like drying or basic annealing, you may only need to program a single setpoint.

Using Ramp and Soak Programs

Many advanced materials require precise control over the rate of heating and cooling. This is achieved with ramp and soak programming.

A ramp is the rate at which the temperature changes, often set in degrees per minute or hour. A soak is a period where the furnace holds a specific temperature for a set duration. Complex profiles may involve multiple ramp and soak stages.

Adjusting Other Control Parameters

Modern controllers have "other control parameters," which typically refers to the PID (Proportional-Integral-Derivative) settings. These values dictate how aggressively the controller responds to temperature deviations.

While often pre-set, these can be fine-tuned via an "autotune" function. Running an autotune at your target temperature helps the furnace learn how to maintain that setpoint with minimal overshoot or fluctuation.

Understanding the Key Trade-offs

Configuring a furnace involves balancing speed, precision, and material safety. Misunderstanding these trade-offs is a common source of error.

Accuracy vs. Sensor Type

Different thermocouple types offer different ranges and accuracies. A Type K thermocouple is common and versatile, but a Type S or B may be required for higher temperatures or greater accuracy, at a higher cost. Your choice must be reflected in the controller settings.

Speed vs. Material Integrity

Using a very fast ramp rate heats the furnace quickly but can induce thermal shock in sensitive materials, especially ceramics or large components. This can cause cracking or structural failure. A slower, more controlled ramp rate is often safer and yields better results.

Controller Versatility

As noted, these controllers can often be used for other heating equipment. The critical limitation is the amperage range. The controller's internal relay or external output must be rated to handle the power draw of the attached heater. Exceeding this can damage the controller.

Making the Right Choice for Your Goal

Your configuration strategy should be dictated entirely by your process objective.

- If your primary focus is a simple heat-and-hold: Ensure the thermocouple type is correct and set your desired temperature setpoint.

- If your primary focus is processing sensitive materials (e.g., ceramics, composites): Invest time in learning to program the ramp and soak functions to prevent thermal shock and ensure process consistency.

- If your primary focus is using the controller for different equipment: Always verify that the new heater's amperage is within the controller's rated limits and that you have correctly set the corresponding thermocouple type.

Ultimately, mastering the front panel configuration transforms the furnace from a simple oven into a precise materials processing tool.

Summary Table:

| Configuration Step | Key Actions | Purpose |

|---|---|---|

| Thermocouple Setup | Select correct type (e.g., Type K, S) | Ensure accurate temperature readings |

| Temperature Range | Set upper and lower limits | Prevent damage and ensure safety |

| Heating Profile | Program setpoints, ramps, and soaks | Achieve precise thermal cycles |

| Control Parameters | Adjust PID settings or use autotune | Optimize temperature stability |

Ready to enhance your lab's precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong deep customization capabilities, we tailor solutions to meet your unique experimental needs. Contact us today to discuss how our expertise can optimize your furnace configurations and drive better results!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development