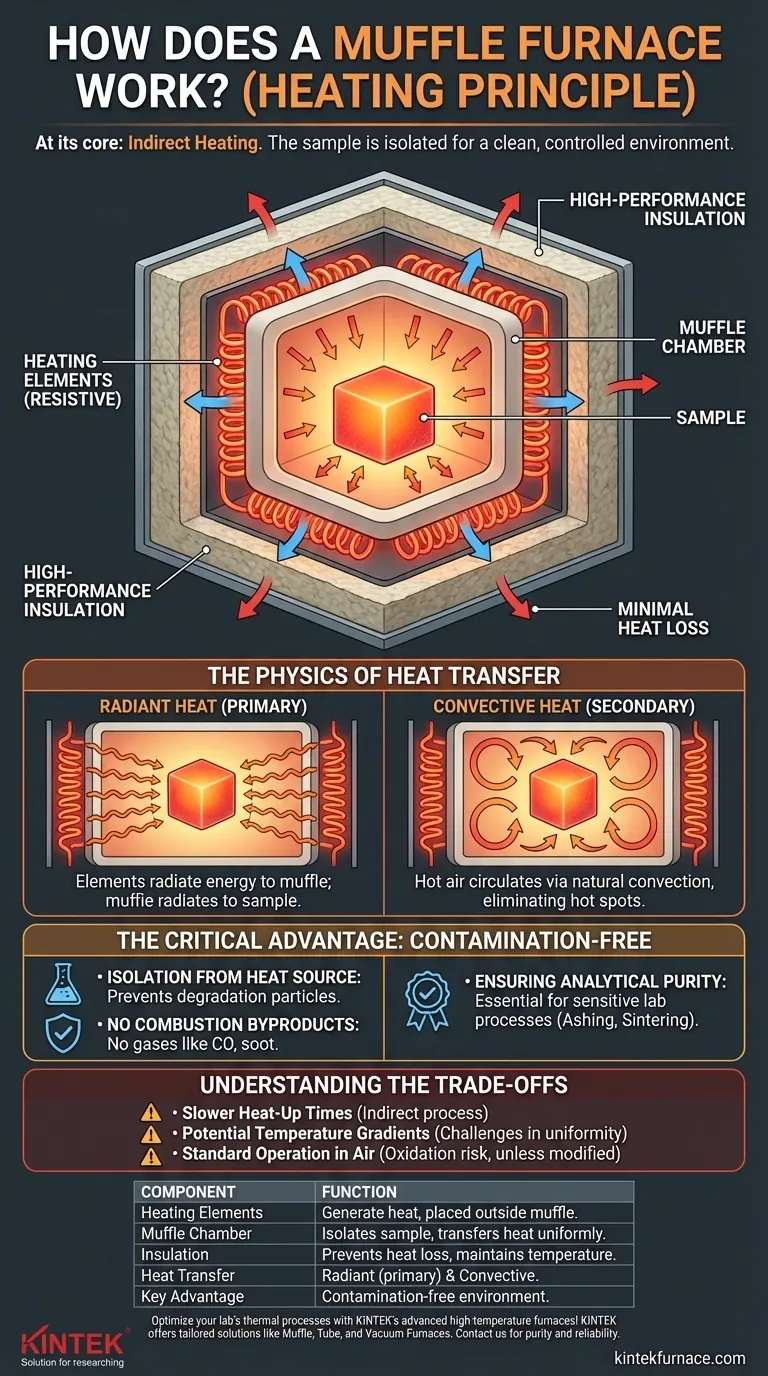

At its core, a muffle furnace operates on the principle of indirect heating. The sample is placed inside a separate, isolated chamber (the "muffle"), which is then heated from the outside. This design intentionally separates the material being heated from the heating elements and any potential contaminants, ensuring a clean and highly controlled environment.

The fundamental purpose of a muffle furnace is not just to generate heat, but to create an exceptionally pure and uniform heating environment. It achieves this by using an inner chamber, or muffle, as a barrier that isolates the sample from the direct heat source.

The Anatomy of Indirect Heating

To understand the working principle, it's essential to look at the key components and how they interact to transfer energy to your sample.

The Heating Elements

The process begins with resistive heating elements, typically made of materials like Kanthal (iron-chromium-aluminum alloy), Nichrome, or silicon carbide. When a strong electrical current passes through these elements, their natural resistance causes them to become extremely hot.

These elements are strategically placed around the outside of the central chamber.

The Muffle Chamber

The "muffle" is the heart of the furnace. It is a box-like chamber made from high-temperature, thermally conductive ceramic materials like alumina.

This chamber contains the sample but is sealed off from the heating elements. Its job is to absorb the heat generated by the elements and then transfer that heat uniformly to the sample inside.

The Insulation

Surrounding the entire assembly is a thick layer of high-performance insulation. This insulation is critical for preventing heat from escaping into the room.

This ensures the furnace can reach and maintain very high temperatures (often over 1000°C) efficiently and with high stability.

The Physics of Heat Transfer

The muffle furnace employs two primary mechanisms to heat the sample evenly. This dual-mode transfer is key to its performance.

Radiant Heat

The primary method of heat transfer is thermal radiation. The scorching hot heating elements radiate thermal energy, which is absorbed by the outer walls of the muffle chamber.

The inner walls of the muffle then become hot and radiate this energy inward, heating the sample from all sides without any physical contact.

Convective Heat

Simultaneously, the air trapped inside the sealed muffle chamber becomes hot. This heated air begins to circulate via natural convection, transferring heat and helping to eliminate hot spots.

This combination of radiation and convection is what allows the furnace to achieve a highly uniform temperature distribution throughout the sample chamber.

The Critical Advantage: A Contamination-Free Environment

The principle of indirect heating is not just a design choice; it is the furnace's defining feature, enabling applications where purity is paramount.

Isolation from the Heat Source

Over time, heating elements can degrade and shed microscopic particles. The muffle acts as a physical barrier, ensuring these particles do not fall onto and contaminate the sample.

Protection from Combustion Byproducts

Unlike fuel-fired furnaces, which produce combustion gases like carbon monoxide and soot, an electric muffle furnace has no such byproducts. This guarantees that the sample does not undergo unintended chemical reactions.

Ensuring Analytical Purity

This clean environment is essential for sensitive laboratory processes like ashing, sintering, or gravimetric analysis, where any foreign material would corrupt the results.

Understanding the Trade-offs

While highly effective, the muffle furnace design comes with inherent trade-offs that are important to recognize for proper application.

Slower Heat-Up Times

Because the heat must first transfer to the muffle and then to the sample, the overall process is less direct. This can result in slower temperature ramp rates compared to direct-fired or induction furnaces.

Potential for Temperature Gradients

While designed for uniformity, achieving perfect heat distribution is a challenge. The quality of the muffle material and furnace design determines how evenly heat is transferred, and minor temperature gradients can still exist.

Standard Operation in Air

A standard muffle furnace heats a sample in a static air atmosphere. While this prevents contamination from the furnace, it does not protect the sample from oxidation. For processes requiring an inert atmosphere (like nitrogen or argon), a specially modified furnace with gas ports is necessary.

Making the Right Choice for Your Goal

Understanding this principle allows you to determine if a muffle furnace is the correct instrument for your specific task.

- If your primary focus is analytical purity: A muffle furnace is non-negotiable for applications like ashing or trace metal analysis, as it prevents sample contamination.

- If your primary focus is uniform heating of sensitive materials: The combination of radiant and convective heat within an isolated chamber provides a stable and gentle heating environment ideal for ceramics, glass, or heat treatment.

- If your primary focus is speed and high throughput: You must evaluate if the slower heating cycles of a muffle furnace are an acceptable trade-off for your process compared to direct heating methods.

By isolating the sample, the muffle furnace provides unparalleled control over the purity of your thermal processing.

Summary Table:

| Component | Function |

|---|---|

| Heating Elements | Generate heat via electrical resistance, placed outside muffle. |

| Muffle Chamber | Isolates sample, absorbs and transfers heat uniformly. |

| Insulation | Prevents heat loss, maintains high temperatures efficiently. |

| Heat Transfer | Combines radiant (primary) and convective methods for even heating. |

| Key Advantage | Ensures contamination-free environment for sensitive processes. |

Optimize your lab's thermal processes with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, delivering purity, uniformity, and reliability. Contact us today to discuss how we can enhance your research and production efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?