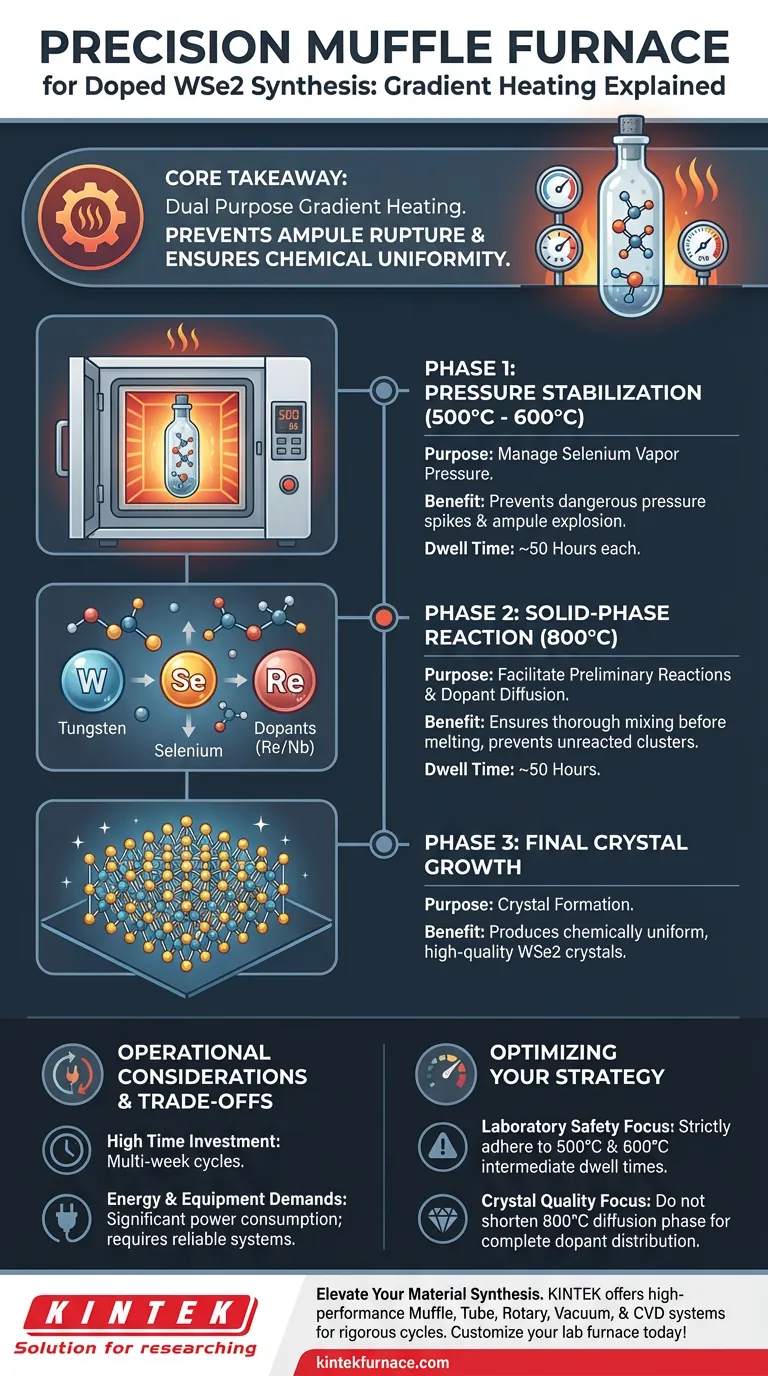

A precision muffle furnace is the critical control mechanism used to manage the volatile thermodynamics involved in synthesizing doped Tungsten Diselenide (WSe2). It executes a rigorous multi-stage heating program—typically holding at 500°C, 600°C, and 800°C—to prevent dangerous pressure spikes in sealed vessels and to ensure the chemical ingredients mix uniformly.

Core Takeaway: The gradient heating process serves a dual purpose: it prevents the physical rupture of sealed ampules by managing vapor pressure, and it drives slow solid-phase reactions to ensure dopants are evenly distributed before the final high-temperature growth phase.

Managing Thermodynamics and Safety

Preventing Ampule Rupture

The synthesis of WSe2 typically occurs within a sealed quartz ampule. If the temperature is raised too quickly, the volatile components (specifically Selenium) vaporize rapidly, causing a massive internal pressure spike.

A precision muffle furnace mitigates this risk by regulating the rate of thermal energy increase. By slowly ramping up the temperature, the furnace ensures the internal pressure remains within the mechanical limits of the quartz container.

The Role of Staged Heating

The primary reference highlights a specific protocol involving holding times at 500°C and 600°C.

These dwell times act as pressure release valves in a chemical sense. They allow the reactants to interact and stabilize at intermediate energy levels, preventing the runaway pressure buildup that leads to explosion.

Ensuring Chemical Uniformity

Promoting Solid-Phase Reactions

Beyond safety, the gradient heating method is essential for material quality. The extended holding periods—often 50 hours at each stage—facilitate preliminary solid-phase reactions.

This creates a controlled environment where Tungsten, Selenium, and dopants (such as Rhenium or Niobium) can begin to bond chemically without melting.

Achieving Homogeneity Before Growth

Rapid heating often leads to clusters of unreacted material or uneven doping.

By maintaining the mixture at 800°C for a prolonged period, the furnace ensures that dopants diffuse thoroughly into the WSe2 matrix. This establishes a chemically uniform precursor state, which is a strict requirement for high-quality crystal growth in the final stages.

Operational Considerations and Trade-offs

High Time Investment

The most significant trade-off of using a precision gradient approach is the process duration. With multiple stages requiring 50-hour holds, a single synthesis cycle can take over a week to complete.

Energy and Equipment Demands

Running a furnace at high temperatures for hundreds of hours consumes significant energy.

Furthermore, this method requires highly reliable equipment; a power failure or element burnout during the week-long cycle can ruin the batch or cause the thermal shock the process was designed to avoid.

Optimizing Your Synthesis Strategy

To apply this to your specific project needs:

- If your primary focus is laboratory safety: strictly adhere to the intermediate dwell times (500°C and 600°C) to manage the high vapor pressure of Selenium and preventing ampule explosions.

- If your primary focus is crystal quality: Do not shorten the 800°C insulation phase, as this timeframe is critical for the complete diffusion of dopants like Rhenium or Niobium.

Precision in heating is not just about temperature; it is the difference between a high-quality crystal and a shattered ampule.

Summary Table:

| Heating Stage | Temperature | Purpose | Benefit |

|---|---|---|---|

| Phase 1 | 500°C - 600°C | Pressure Stabilization | Prevents ampule rupture from Selenium vaporization |

| Phase 2 | 800°C | Solid-Phase Reaction | Ensures thorough diffusion of dopants like Re or Nb |

| Phase 3 | Final Growth | Crystal Formation | Produces high-quality, chemically uniform WSe2 crystals |

Elevate Your Material Synthesis with KINTEK

Precision is the thin line between a high-quality crystal and a failed batch. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to handle the rigorous 100+ hour cycles required for doped WSe2 synthesis.

Our customizable lab furnaces provide the thermal stability and programmable accuracy needed to manage volatile thermodynamics and ensure perfect dopant diffusion. Contact us today to optimize your laboratory's high-temperature capabilities!

Visual Guide

References

- Monaam Benali, Zdeněk Sofer. 2D Rhenium- and Niobium-Doped WSe<sub>2</sub> Photoactive Cathodes in Photo-Enhanced Hybrid Zn-Ion Capacitors. DOI: 10.1021/acsanm.4c01405

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the disadvantages of a muffle furnace? Understanding Key Limitations for Your Lab

- What are the disadvantages of muffle furnace? Understanding the Trade-offs of Indirect Heating

- What is a muffle furnace and how does it relate to laboratory furnaces? Discover Its Key Benefits for Your Lab

- How is a muffle furnace applied in the food industry? Essential for Ash and Moisture Analysis

- What is the primary role of high-precision muffle furnaces in the sintering process of high-entropy alloys?

- Why must ceramic shells undergo high-temperature sintering? Ensure Integrity for High-Melting-Point Alloys

- What is the significance of the heating and holding curves in a muffle furnace? Sinter High-Quality PTFE Composites

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance