While highly precise, a muffle furnace is not a universally ideal heating solution. Its primary disadvantages are rooted in its design, leading to potentially lower heating efficiency and higher energy consumption compared to direct-heating methods. Crucially, its fundamental structure makes it entirely unsuitable for any application that requires a vacuum environment.

A muffle furnace excels at providing a clean, uniform, and precisely controlled heating environment. However, this is achieved by sacrificing speed, energy efficiency, and the ability to control the atmospheric pressure, making it the wrong choice for vacuum-dependent or high-throughput processes.

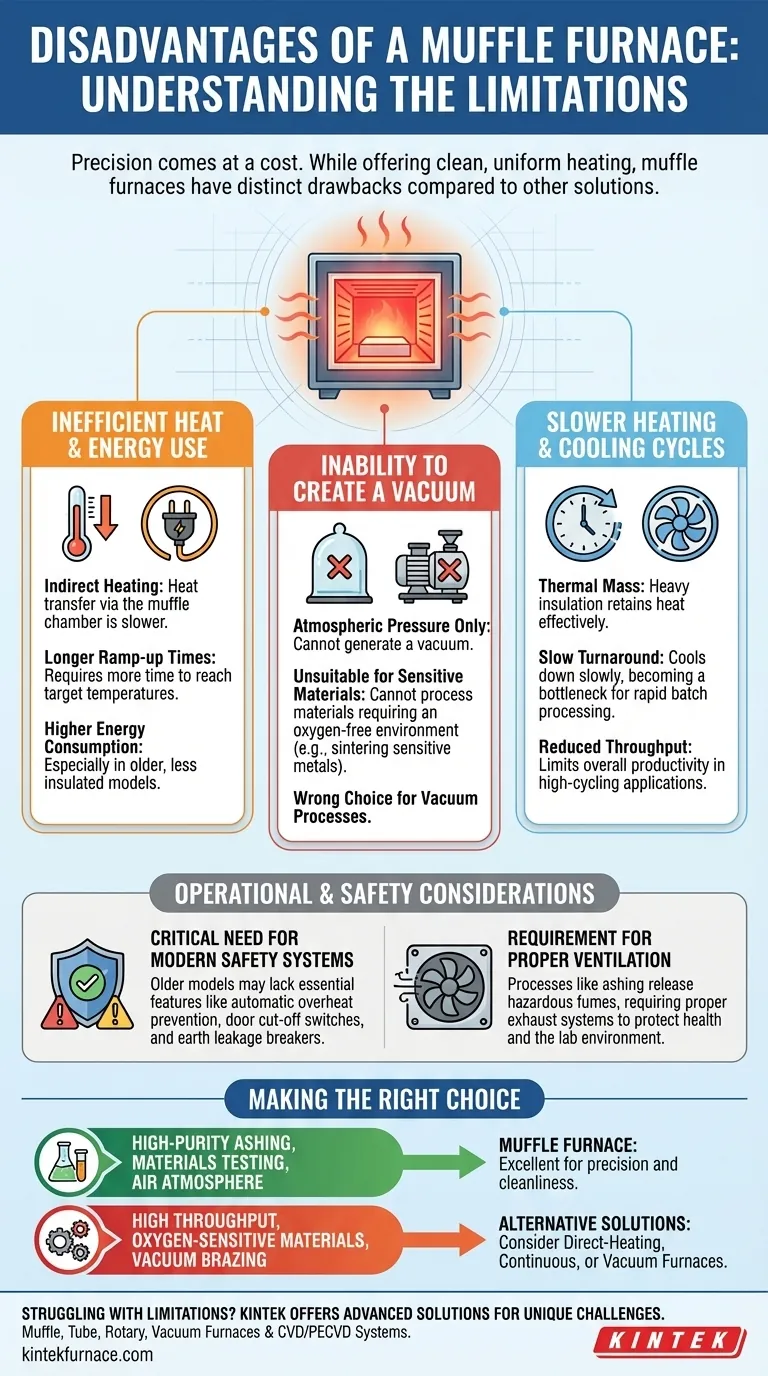

Analyzing the Core Limitations

The defining feature of a muffle furnace—an inner chamber (the "muffle") that isolates the sample from the heating elements—is the source of both its strengths and its weaknesses.

Inefficient Heat Transfer and Energy Use

A significant drawback is the indirect nature of the heating process. The elements heat the chamber, which then radiates heat to the sample.

This indirect transfer can be less efficient than direct heating, potentially leading to longer ramp-up times to reach the target temperature. In some models, particularly older or less-insulated ones, this inefficiency results in higher overall energy consumption to maintain a set temperature.

Inability to Create a Vacuum

This is the most critical operational limitation. Muffle furnaces are designed to operate at ambient atmospheric pressure.

Their construction does not allow for the creation of a vacuum. For processes like sintering sensitive metals or certain advanced material treatments that require an oxygen-free environment, a muffle furnace is unsuitable. In these cases, a dedicated vacuum furnace is the only appropriate choice.

Slower Heating and Cooling Cycles

The same heavy insulation that provides excellent temperature stability and uniformity also retains heat very effectively.

While great for steady-state operation, this thermal mass means the furnace cools down slowly. For labs or production facilities that require rapid cycling between batches, this slow turnaround time can become a significant bottleneck, reducing overall throughput.

Operational and Safety Considerations

Beyond inherent design limitations, practical operational factors must be considered. A poorly specified furnace can introduce significant risks.

The Critical Need for Modern Safety Systems

A muffle furnace operates at extreme temperatures, making safety non-negotiable. A disadvantage of older or cheaper models is the absence of modern, automated safety features.

A reliable furnace must include systems like automatic overheat prevention, a door switch that cuts power when opened, and an earth leakage breaker. Advanced units also feature self-diagnostic functions to detect sensor errors or heater failures, preventing catastrophic incidents. A furnace lacking these is a serious liability.

Requirement for Proper Ventilation

Many heat treatment processes, such as ashing or debinding, release fumes, smoke, or volatile compounds.

If the furnace is not equipped with a proper ventilation or exhaust system, these gases can pose a health hazard and potentially damage the lab environment. This makes proper siting and installation critical, adding a layer of complexity and cost.

Understanding the Trade-offs

Choosing a muffle furnace involves balancing its distinct advantages against its clear limitations.

Precision vs. Speed

The muffle design provides exceptional temperature uniformity and isolates the workload from contamination from the heating elements.

The trade-off for this precision is speed. Processes will almost always take longer than in a direct-heating furnace due to the thermal lag created by the intermediate chamber.

Contamination Control vs. Atmospheric Control

The furnace provides excellent control over particulate contamination from heating elements.

However, it provides zero control over atmospheric contamination. The sample is fully exposed to ambient air (oxygen and nitrogen), which can be detrimental for materials prone to oxidation at high temperatures.

Making the Right Choice for Your Application

To select the correct equipment, you must align the furnace's capabilities with your specific process goals.

- If your primary focus is high-purity ashing, materials testing, or heat treatment in an air atmosphere: A muffle furnace is an excellent choice, valued for its precision and cleanliness.

- If your primary focus is high throughput and rapid processing cycles: The slower heating and cooling times of a muffle furnace may be a critical bottleneck, warranting investigation into direct-heating or continuous furnace types.

- If your primary focus is processing oxygen-sensitive materials or performing vacuum brazing: A muffle furnace is fundamentally the wrong tool; you must use a vacuum or inert gas furnace.

Ultimately, an informed decision comes from clearly understanding your material's requirements and your operational priorities.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Inefficient Heat Transfer | Longer ramp-up times & higher energy consumption |

| Inability to Create a Vacuum | Unsuitable for oxygen-sensitive materials or vacuum processes |

| Slow Heating/Cooling Cycles | Reduced throughput for rapid batch processing |

| Requires Modern Safety Systems | Critical for preventing overheating & ensuring operator safety |

| Needs Proper Ventilation | Essential to handle fumes from processes like ashing or debinding |

Struggling with the limitations of your current furnace? KINTEK understands that every lab has unique thermal processing challenges. Our team leverages exceptional R&D and in-house manufacturing to provide advanced solutions that overcome common drawbacks. Whether you need faster cycle times, vacuum capabilities, or a custom-designed system, we can help.

Our product line includes:

- Muffle Furnaces

- Tube Furnaces

- Rotary Furnaces

- Vacuum & Atmosphere Furnaces

- CVD/PECVD Systems

Let us design a furnace that precisely meets your experimental requirements. Contact our experts today to discuss your application and get a tailored solution!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization