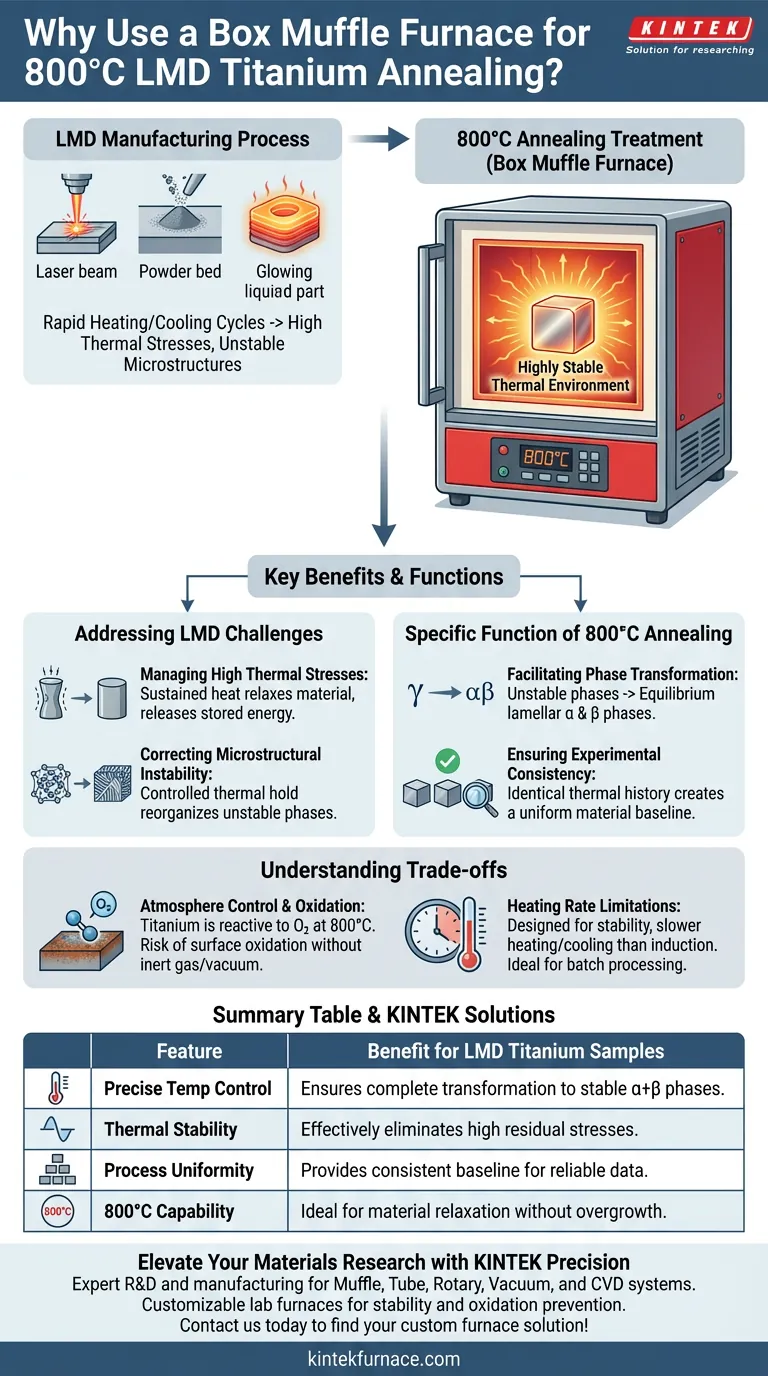

A box muffle furnace is primarily used to create a highly stable thermal environment essential for normalizing titanium alloy samples produced by Laser Melting Deposition (LMD). This specific equipment provides the precise temperature control needed to eliminate significant thermal stresses that naturally accumulate during the rapid heating and cooling cycles of the LMD manufacturing process.

The core purpose of this treatment is to transform unstable microstructures into stable lamellar alpha and beta phases. This creates a uniform material baseline, ensuring that data derived from subsequent hot compression experiments is reliable and comparable.

Addressing the Challenges of LMD Manufacturing

Managing High Thermal Stresses

Laser Melting Deposition creates components by melting metal powder layer by layer. This process generates intense thermal gradients, leaving the material with high levels of residual internal stress.

If left untreated, these stresses can lead to warping or unpredictable mechanical behavior. The muffle furnace provides the sustained heat required to relax the material and release these stored energies.

Correcting Microstructural Instability

The rapid solidification inherent to LMD freezes the titanium alloy in an unstable state. The microstructure is often non-uniform immediately after fabrication.

To achieve a predictable material, these unstable phases must be reorganized. This requires a controlled thermal hold that only a stable furnace environment can provide.

The Specific Function of 800°C Annealing

Facilitating Phase Transformation

Annealing at 800°C is a targeted heat treatment designed to alter the alloy's internal structure. Under these conditions, the unstable phases transform into equilibrium lamellar $\alpha$ and $\beta$ phases.

This transformation is critical for stabilizing the alloy. It ensures the metal achieves the specific mechanical properties required for high-performance applications.

Ensuring Experimental Consistency

For researchers conducting hot compression experiments, the initial state of the sample is paramount. Variations in the starting microstructure would render comparative data useless.

The box muffle furnace ensures every sample undergoes identical thermal history. This guarantees a consistent initial state, allowing for accurate analysis of the material's behavior under load.

Understanding the Trade-offs

Atmosphere Control and Oxidation

While muffle furnaces offer excellent temperature stability, standard models typically operate with an air atmosphere. Titanium is highly reactive to oxygen at 800°C.

Unless the furnace is equipped with a specific inert gas setup or a vacuum retort, surface oxidation may occur. This often requires subsequent machining or polishing to remove the oxide layer before testing.

Heating Rate Limitations

Muffle furnaces are designed for stability rather than rapid thermal cycling. They are excellent for soaking samples at a fixed temperature but are generally slower to heat up and cool down compared to induction heating systems.

This makes them ideal for batch processing where time is less critical than temperature uniformity. However, they may be a bottleneck in high-throughput manufacturing environments.

Making the Right Choice for Your Goal

To maximize the value of your annealing process, consider your primary objective:

- If your primary focus is Research Validity: Prioritize the muffle furnace for its ability to create a uniform, reproducible baseline microstructure, which is essential for publishing valid comparative data.

- If your primary focus is Material Integrity: Ensure the furnace maintains a strictly stable temperature at 800°C to fully resolve residual stresses and prevent warping during later machining.

By stabilizing the microstructure today, you ensure the reliability of your material performance data tomorrow.

Summary Table:

| Feature | Benefit for LMD Titanium Samples |

|---|---|

| Precise Temperature Control | Ensures complete transformation into stable $\alpha$ and $\beta$ phases. |

| Thermal Stability | Effectively eliminates high residual stresses from rapid laser melting cycles. |

| Process Uniformity | Provides a consistent baseline for reliable subsequent hot compression data. |

| 800°C Capability | Ideal temperature for relaxing material energy without grain overgrowth. |

Elevate Your Materials Research with KINTEK Precision

Don't let residual stress compromise your research results. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for the rigorous demands of titanium alloy heat treatment. Whether you need standard atmospheric control or advanced vacuum systems to prevent oxidation, our customizable lab furnaces provide the stability your process requires.

Ready to stabilize your microstructure? Contact us today to find your custom furnace solution!

Visual Guide

References

- Jianhua Sun, Zhonggang Sun. Ti6Al4V-0.72H on the Establishment of Flow Behavior and the Analysis of Hot Processing Maps. DOI: 10.3390/cryst14040345

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the significance of a high-temperature muffle furnace in CaO powder modification? Unlock Precise Crystallinity

- What makes uniform heating important in a muffle furnace? Ensure Precise, Reliable Results Every Time

- How does a muffle furnace ensure contamination-free heating? Discover Its Isolation Design for Purity

- What is the primary technical function of a Muffle Furnace in CoMn2O4 synthesis? Achieve Precise Nano-Spinel Calcination

- What temperature ranges do different types of muffle furnaces operate at? Find Your Perfect Heat Solution

- What are the temperature capabilities of muffle furnaces? Find Your Perfect High-Temp Solution

- Why are muffle furnaces considered indispensable in laboratory and industrial settings? Discover Their Key Benefits for Clean, Controlled Heating

- What is the primary function of a high-temperature muffle furnace in graphene oxide synthesis? Maximize Carbon Yield