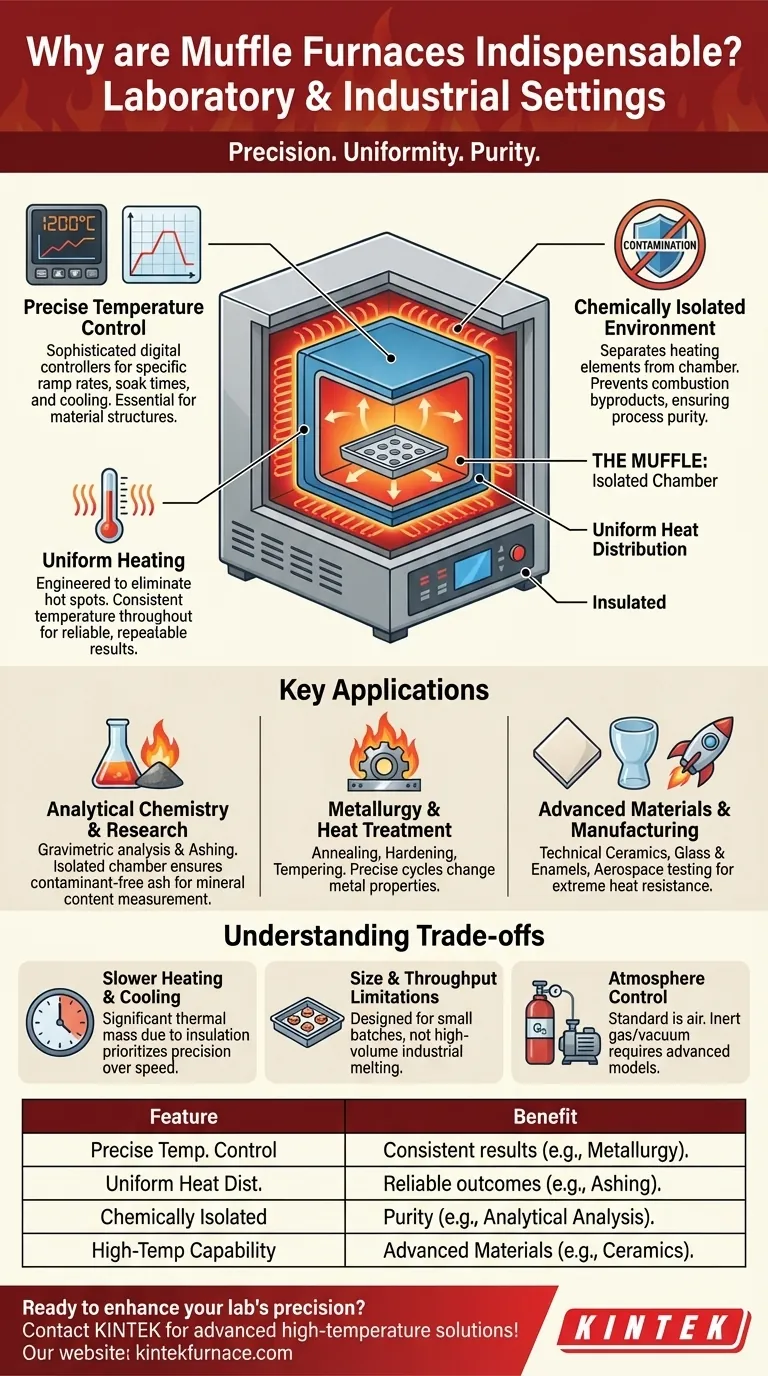

In any process requiring extreme heat, control is paramount. Muffle furnaces are considered indispensable in laboratory and industrial settings because they deliver three critical capabilities simultaneously: precise, high-temperature heating; uniform heat distribution throughout a chamber; and a chemically isolated environment that prevents contamination of the material being processed. This unique combination ensures that processes are not just hot, but also clean, consistent, and perfectly repeatable.

The core value of a muffle furnace lies not just in its ability to generate high heat, but in its design that separates the heating elements from the processing chamber. This "muffle" is the key, ensuring the material is altered only by temperature, not by byproducts of combustion or electrical interference.

The Core Principles of Operation

A muffle furnace's indispensability stems from its fundamental design, which solves common challenges in high-temperature work.

The 'Muffle': Isolating the Process from Contamination

The defining feature is the muffle—a sealed inner chamber that contains the sample. The heating elements are located on the outside of this chamber.

This design completely isolates the material from the heat source. It prevents any contaminants from the combustion process (in fuel-fired models) or the heating elements themselves from affecting the sample, ensuring process purity.

Achieving Precise Temperature Control

Modern muffle furnaces use sophisticated digital controllers. These allow operators to program precise temperature profiles, including specific ramp rates (how fast it heats up), soak times (how long it stays at a temperature), and cooling rates.

This level of control is essential for creating specific molecular or crystalline structures in materials science and metallurgy.

Ensuring Uniform Heating

The furnace is engineered to eliminate hot spots. The insulation and placement of heating elements ensure that the temperature is consistent throughout the entire chamber.

For applications like heat-treating multiple small parts or ashing a sample for analysis, this uniformity guarantees that every part of the sample experiences the exact same thermal conditions, leading to reliable and consistent results.

Key Applications Across Industries

The furnace's combination of heat, control, and cleanliness makes it a versatile tool across a wide range of fields.

Analytical Chemistry and Research

Muffle furnaces are a cornerstone of analytical labs for gravimetric analysis, specifically a process called ashing. A sample is heated to a high temperature to burn off all organic matter, leaving only the inorganic ash.

The isolated chamber is critical here, as it ensures the remaining ash is free from external contaminants, allowing for accurate measurement of the material's mineral content.

Metallurgy and Heat Treatment

In metallurgy, the physical properties of a metal are changed by carefully controlled heating and cooling cycles.

Processes like annealing (softening), hardening, and tempering rely on the furnace's ability to execute precise temperature programs to achieve desired changes in the metal's molecular structure.

Advanced Materials and Manufacturing

The applications extend deep into industrial production and R&D for creating specialized materials.

- Technical Ceramics: Firing ceramics at high temperatures to achieve specific densities and strengths.

- Glass and Enamels: Used for melting glass or fusing enamel coatings onto metal.

- Aerospace: Testing the flame retardancy and thermal resistance of components under extreme heat.

Understanding the Trade-offs

While indispensable for its specific strengths, the design of a muffle furnace presents practical trade-offs.

Slower Heating and Cooling Rates

The same heavy insulation and sealed chamber that provide temperature uniformity also create significant thermal mass.

This means muffle furnaces generally heat up and cool down more slowly than direct-fire kilns or induction furnaces. They prioritize precision over speed.

Size and Throughput Limitations

Most muffle furnaces, especially in laboratory settings, are relatively small, benchtop devices. They are designed for high-precision processing of small samples or batches.

They are not suited for large-scale industrial melting or continuous, high-volume production, which requires different types of industrial furnaces.

Atmosphere Control

A standard muffle furnace provides an air atmosphere and prevents contamination from the outside. Creating a specific internal atmosphere (such as inert gas like argon or a vacuum) requires more advanced and costly models equipped with gas ports and vacuum seals.

Making the Right Choice for Your Goal

The decision to use a muffle furnace should be based on the specific requirements of your process.

- If your primary focus is analytical purity: The isolated chamber is essential for applications like ashing, where preventing sample contamination is the top priority.

- If your primary focus is precise material transformation: The combination of uniform heat and programmable temperature control is critical for achieving specific outcomes in metallurgy, ceramics, and R&D.

- If your primary focus is high-volume, rapid heating: You may need to evaluate other options like induction or direct-fired furnaces, as the thermal mass of a muffle furnace makes it less suitable for speed.

Ultimately, a muffle furnace is the definitive choice whenever the integrity, purity, and repeatability of your high-temperature process are non-negotiable.

Summary Table:

| Feature | Benefit |

|---|---|

| Precise Temperature Control | Enables accurate heating profiles for consistent results in material science and metallurgy. |

| Uniform Heat Distribution | Eliminates hot spots, ensuring reliable outcomes in applications like ashing and heat treatment. |

| Chemically Isolated Chamber | Prevents contamination, crucial for analytical purity in processes such as gravimetric analysis. |

| High-Temperature Capability | Supports extreme heat requirements for advanced materials like ceramics and aerospace components. |

Ready to enhance your lab's precision and efficiency with a custom high-temperature furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for clean, controlled heating. Contact us today to discuss how our furnaces can deliver reliable, contamination-free results for your applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment