The primary function of a high-temperature muffle furnace in this context is to provide a strictly controlled thermochemical environment for converting organic biomass into carbon. specifically, it facilitates a two-step transformation: carbonizing biological material at 850°C under an inert atmosphere, and subsequently activating the resulting product at 350°C to create high-activity carbonaceous materials.

By isolating the biomass in a precise thermal environment, the muffle furnace drives the transition from complex organic waste to high-activity carbon, ensuring the structural stability and consistency necessary for high-quality graphene oxide.

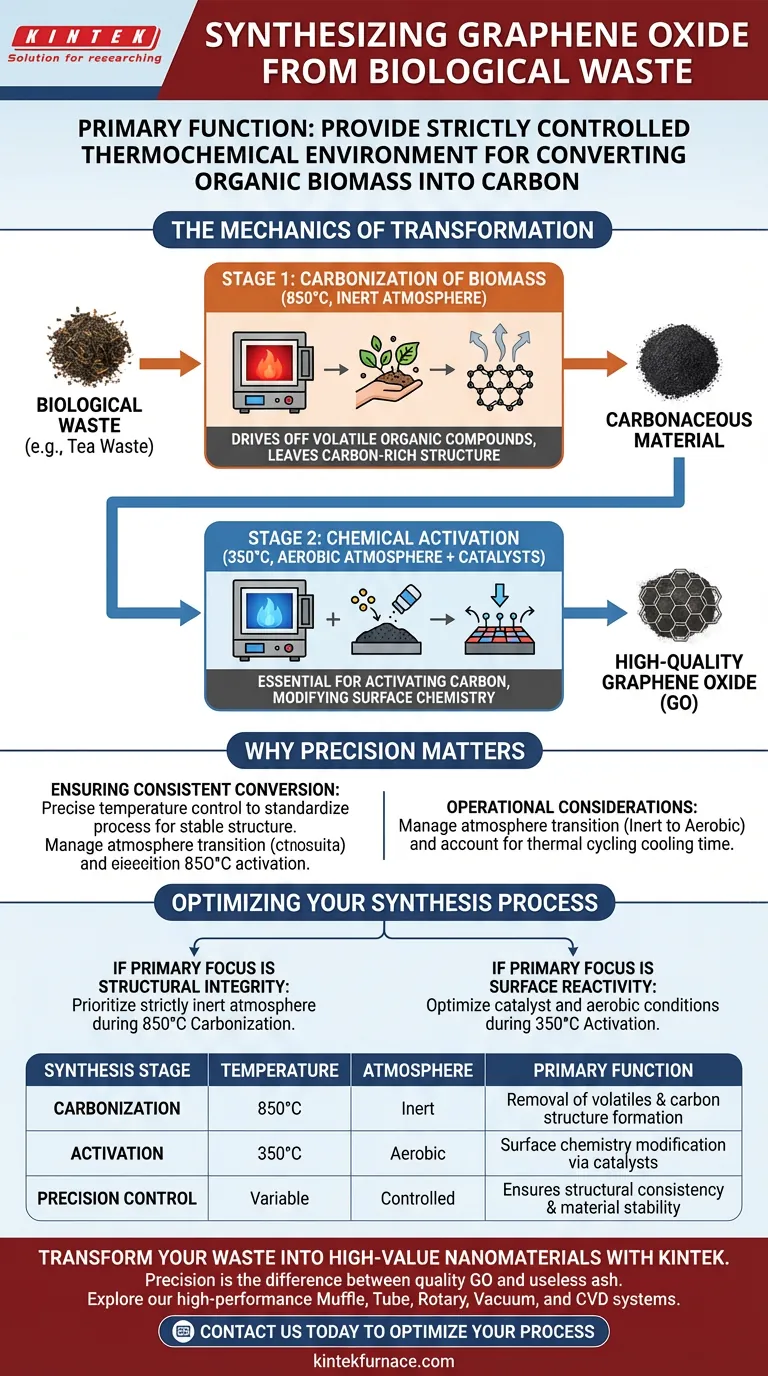

The Mechanics of Transformation

To understand the role of the furnace, you must look at the specific chemical changes it enables. The muffle furnace does not simply "burn" the waste; it engineers the material through specific temperature stages.

Carbonization of Biomass

The initial critical step involves heating the biological source, such as tea waste, to 850°C.

This process must occur within an inert atmosphere to prevent the material from turning into ash.

At this temperature, the furnace drives off volatile organic compounds, leaving behind a carbon-rich structure.

Chemical Activation

Following carbonization, the furnace is utilized for a secondary process at a significantly lower temperature of 350°C.

Unlike the first stage, this step occurs in an aerobic environment and involves the use of catalysts.

This phase is essential for activating the carbon, modifying its surface chemistry to eventually yield graphene oxide.

Why Precision Matters

The success of synthesizing graphene oxide from biological waste relies heavily on the stability of the equipment.

Ensuring Consistent Conversion

Biological waste is complex and variable.

The muffle furnace provides precise temperature control, which is necessary to standardize the conversion process.

Without this stability, the resulting carbonaceous material would lack the consistent structure required for high-quality graphene applications.

Operational Considerations and Trade-offs

While the muffle furnace is the engine of this synthesis, understanding its limitations is vital for reproducible results.

Atmosphere Management

A common pitfall is the mismanagement of the furnace atmosphere between stages.

The transition from an inert atmosphere (at 850°C) to an aerobic environment (at 350°C) requires careful handling.

Failing to maintain the inert atmosphere during the high-temperature stage will result in the complete combustion (oxidation) of your sample, leaving you with useless ash rather than carbon.

Thermal Cycling Considerations

Rapidly changing temperatures between the 850°C carbonization and 350°C activation stages can stress both the equipment and the material.

Process engineers must account for the cooling time required to shift between these distinct thermal regimes safely.

Optimizing Your Synthesis Process

To derive the best possible graphene oxide from biological waste, tailor your approach to your specific outcome.

- If your primary focus is structural integrity: Prioritize maintaining a strictly inert atmosphere during the 850°C carbonization phase to maximize the carbon yield.

- If your primary focus is surface reactivity: Dedicate attention to the 350°C activation phase, ensuring the catalyst and aerobic conditions are optimized for maximum chemical activity.

Mastering the thermal profile of your muffle furnace is the single most important factor in turning low-value waste into high-value nanomaterials.

Summary Table:

| Synthesis Stage | Temperature | Atmosphere | Primary Function |

|---|---|---|---|

| Carbonization | 850°C | Inert | Removal of volatiles & carbon structure formation |

| Activation | 350°C | Aerobic | Surface chemistry modification via catalysts |

| Precision Control | Variable | Controlled | Ensures structural consistency & material stability |

Transform Your Waste into High-Value Nanomaterials with KINTEK

Precision is the difference between high-quality graphene oxide and useless ash. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to handle the rigorous thermal profiles of biomass conversion. Whether you need a standard setup or a fully customizable solution for unique research needs, our lab high-temp furnaces provide the stability and atmosphere control required for superior material engineering.

Ready to optimize your synthesis process? Contact us today to discover how KINTEK can enhance your lab's efficiency and output.

Visual Guide

References

- Sovandeb Sen, Susmita Kundu. Bio-waste derived reduced graphene oxide (rGO) decorated Cr (III) doped α-Fe2O3 nanocomposite for selective ppm-level acetone sensing at room temperature: Potential approach towards non-invasive diagnosis of diabetic biomarker. DOI: 10.1007/s42114-025-01241-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of muffle furnaces compared to other heating devices? Superior Temperature Control and Purity

- What is the function of a high-precision resistance furnace in the Al-Mg-Si alloy melting process? Achieve 750°C Stability

- What specialized processes can a box furnace facilitate? Unlock Precision Material Transformation

- How should the temperature be managed when using a muffle furnace? Master Precise Control for Safety & Accuracy

- What is the purpose of ashing in a muffle furnace? Unlock Material Purity and Quality Insights

- Why is a constant temperature oven better than a heating plate for annealing Cs3Cu2I5:Tb films? Expert Comparison

- What role does a high-temperature box furnace play in the pre-calcination of LLZTO? Master Garnet Phase Synthesis

- What is the role of a muffle furnace in nitrogen-doped carbon precursor synthesis? Key Roles in Thermal Condensation