The fundamental advantages of a muffle furnace are its ability to deliver superior temperature uniformity, high-precision control, and an isolated environment for the sample. Unlike simpler ovens, a muffle furnace separates the material being heated from the heating elements, preventing contamination and allowing for specialized atmospheric conditions while reaching exceptionally high temperatures.

A muffle furnace isn't just a hotter oven; it's a controlled thermal processing environment. Its core advantage lies in isolating the sample from the heating source, which is the key to achieving unparalleled process purity, temperature uniformity, and repeatability.

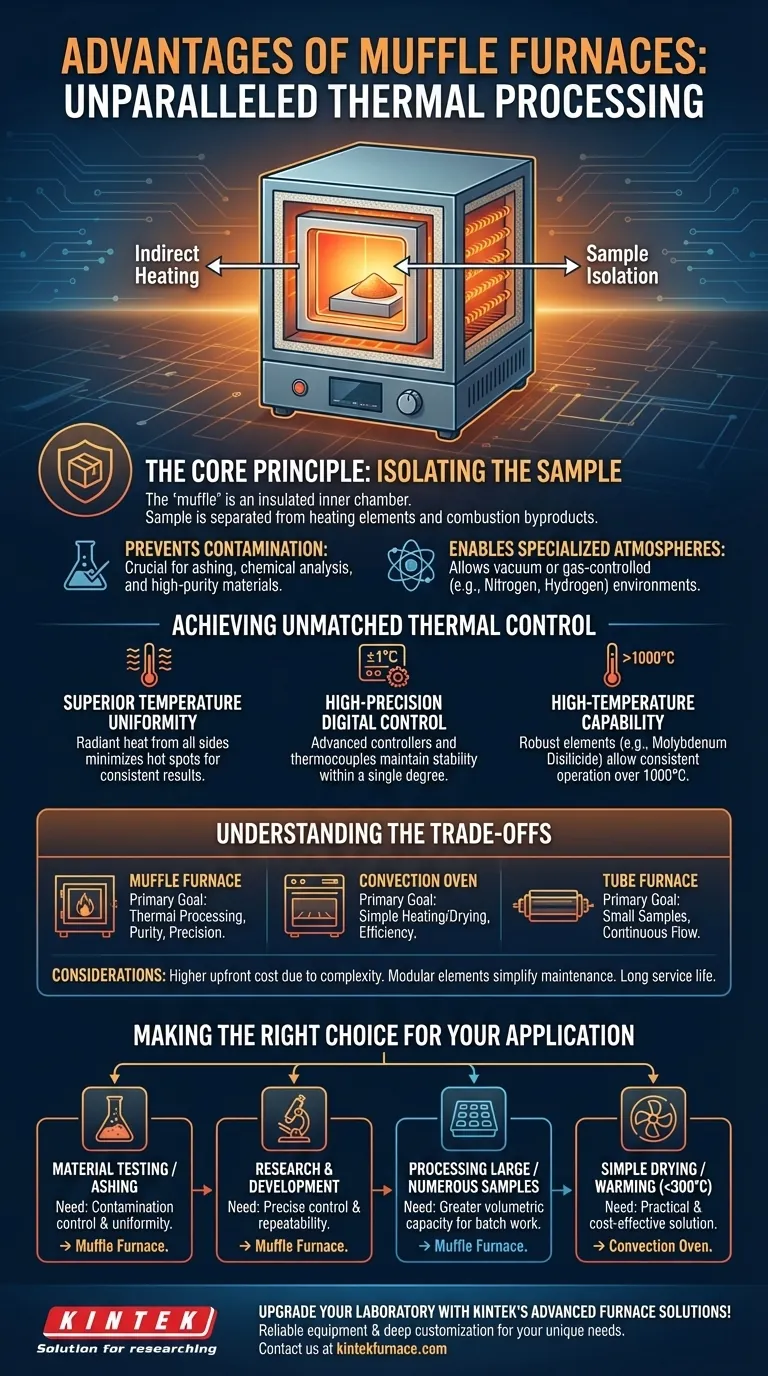

The Core Principle: Isolating the Sample

The defining feature of a muffle furnace is the "muffle"—an insulated inner chamber that contains the sample. This design is the source of its primary benefits.

What is a "Muffle"?

Think of the muffle as a box-within-a-box. The outer box contains the heating elements, which heat the inner box (the muffle) through radiation and convection.

Your sample sits inside this inner box, never coming into direct contact with the heating elements or any byproducts of combustion in fuel-fired models.

Preventing Process Contamination

By separating the sample from the heating source, the muffle design prevents impurities from the elements from flaking off and contaminating the material.

This is critical for applications like ashing, chemical analysis, or creating high-purity materials where even trace contamination can invalidate results.

Enabling Specialized Atmospheres

Because the inner chamber is a self-contained unit, the atmosphere within it can be carefully controlled.

This allows for thermal processing in a vacuum or with specific gases like nitrogen or hydrogen, which is impossible in a standard, non-sealed oven.

Achieving Unmatched Thermal Control

The indirect heating method of a muffle furnace creates a highly stable and predictable thermal environment, which is essential for sensitive processes.

Superior Temperature Uniformity

Heat radiates from the walls of the muffle chamber onto the sample from all sides. This indirect approach minimizes hot spots and ensures a highly uniform temperature throughout the entire chamber.

Premium designs often feature cubed chambers and modular heating plates on multiple sides to further optimize this uniformity.

High-Precision Digital Control

Modern muffle furnaces use advanced digital controllers, such as phase angle-fire SCR power controllers, and high-accuracy thermocouples (e.g., Type 'B').

This combination allows the furnace to maintain a set temperature with minimal fluctuation, often within a single degree, ensuring the process is both precise and repeatable.

High-Temperature Capability

While standard lab ovens top out at a few hundred degrees Celsius, muffle furnaces are built for high-heat applications.

Using robust heating elements made from materials like molybdenum disilicide and high-purity alumina fiber insulation, they can consistently operate at temperatures well over 1000°C.

Understanding the Trade-offs

A muffle furnace is a specialized tool, and its advantages come with certain trade-offs when compared to other heating devices.

Muffle Furnace vs. Convection Oven

A standard convection oven is designed for simple heating and drying at lower temperatures. It circulates hot air directly over the sample, which is efficient but lacks precision and purity.

A muffle furnace is built for thermal processing, where sample isolation, atmospheric control, and temperature uniformity are the primary goals.

Muffle Furnace vs. Tube Furnace

A tube furnace is excellent for processing small samples or for continuous-flow processes. However, its small diameter limits sample size.

A muffle furnace offers significantly more internal volume for batch processing, allowing it to handle larger components or a higher quantity of samples at a similar price point.

Considerations of Cost and Maintenance

Muffle furnaces are more complex and generally have a higher upfront cost than simple ovens due to their advanced insulation, controllers, and sealed chamber construction.

However, features like modular heating elements can simplify maintenance, and their robust, often all-steel construction ensures a long service life, making them cost-effective for critical applications.

Making the Right Choice for Your Application

Selecting the correct heating device depends entirely on your process requirements for temperature, control, and purity.

- If your primary focus is material testing or ashing: The contamination control and superior temperature uniformity of a muffle furnace are essential for accurate results.

- If your primary focus is research and development: The precise digital control and process repeatability ensure your findings are valid and can be consistently replicated.

- If your primary focus is processing large or numerous samples: A muffle furnace provides greater volumetric capacity for batch work compared to a tube furnace.

- If your primary focus is simple drying or warming below 300°C: A standard laboratory convection oven is a more practical and cost-effective solution.

By understanding these core principles, you can confidently select the thermal processing tool that aligns perfectly with your technical requirements.

Summary Table:

| Advantage | Description |

|---|---|

| Superior Temperature Uniformity | Indirect heating minimizes hot spots for even heat distribution. |

| High-Precision Control | Digital controllers maintain temperature within ±1°C for repeatability. |

| Isolated Environment | Muffle chamber prevents contamination and allows controlled atmospheres. |

| High-Temperature Capability | Operates reliably over 1000°C with robust materials like molybdenum disilicide. |

| Batch Processing Capacity | Larger internal volume handles more samples than tube furnaces. |

Upgrade your laboratory's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency, accuracy, and results. Contact us today to discuss how we can support your specific applications and drive innovation in your research!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO