To properly manage the temperature in a muffle furnace, you must use the integrated temperature controller to program your desired heating cycle. This involves setting the target temperature, the rate of temperature increase (ramp rate), and the duration of the heating period (hold time). Throughout the process, it is critical to monitor the furnace's operation to ensure it functions as expected and to prevent accidents or damage to the equipment.

The core principle of muffle furnace temperature management is not just reaching a target temperature, but controlling the entire thermal journey. Mastering the ramp-up, hold, and cool-down phases is essential for ensuring process accuracy, operator safety, and the long-term health of the furnace.

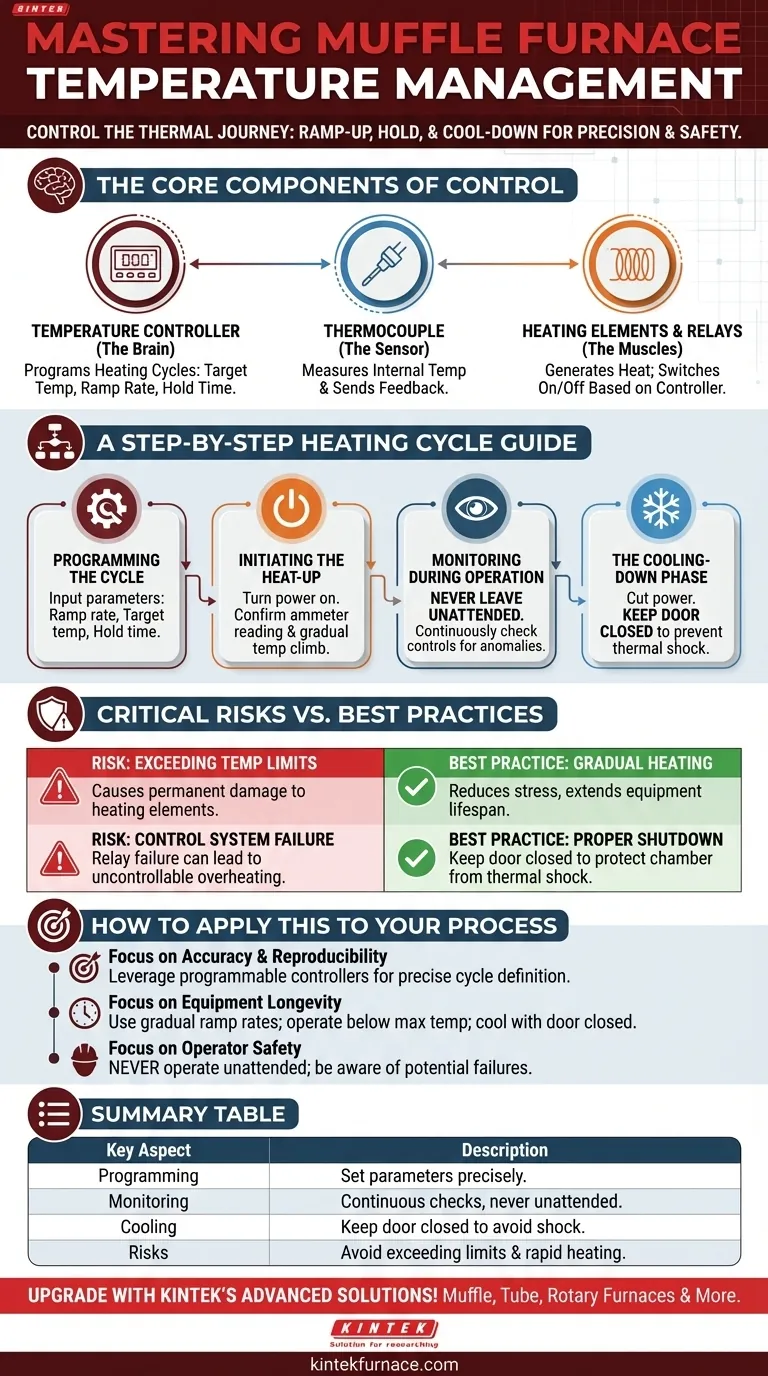

The Core Components of Temperature Control

To effectively manage the furnace, you must first understand the system responsible for controlling its heat. These components work together to execute your programmed instructions.

The Temperature Controller

The controller is the brain of the operation. Modern digital controllers allow you to program precise heating cycles. You can set the exact temperature you need to reach, how fast the furnace heats up, and how long it stays at that temperature.

The Thermocouple

The thermocouple acts as the furnace's nerve ending. It is a sensor placed inside the furnace chamber that continuously measures the actual internal temperature and sends this information back to the controller.

Heating Elements and Relays

The heating elements are the muscles that generate heat. The controller uses an electromagnetic relay to switch these elements on or off based on feedback from the thermocouple, ensuring the internal temperature accurately follows your set program.

A Step-by-Step Guide to a Heating Cycle

A successful heating process is methodical and deliberate. Following these steps ensures both safety and the quality of your results.

Programming the Cycle

Before you begin, use the temperature controller to input your desired parameters. For precise work, this includes the ramp-up rate, the final target temperature, and the hold time. For simpler units, this may just involve setting the target temperature.

Initiating the Heat-Up

Once programmed, turn on the furnace's power. Confirm that the system is working by checking that the ammeter shows a reading and the temperature display begins to climb. The temperature should increase gradually and smoothly.

Monitoring During Operation

Never leave a running furnace unattended. Continuously monitor the temperature display to ensure the automatic controls are functioning correctly. This vigilance is your primary defense against accidents, such as the overheating and burning of furnace wiring.

The Cooling-Down Phase

After the heating cycle is complete, cut the power to the furnace. To protect the furnace chamber from thermal shock and moisture corrosion, keep the door closed until the furnace has cooled down significantly.

Understanding Critical Risks and Best Practices

Effective temperature management is as much about avoiding mistakes as it is about following procedures. Ignoring these risks can lead to equipment failure or hazardous situations.

Risk: Exceeding Temperature Limits

Every muffle furnace has a maximum rated temperature. Pushing the furnace beyond this limit, even for a short time, can permanently damage or destroy the heating elements.

Best Practice: Gradual Heating

Rapidly increasing the temperature puts immense stress on both the furnace chamber and the heating elements, reducing their lifespan. A slower, more gradual ramp rate is always preferable for equipment longevity.

Risk: Control System Failure

While rare, automatic temperature controllers can fail. If the relay sticks in the "on" position, the furnace will continue heating uncontrollably. This is why manual, continuous monitoring is non-negotiable.

Best Practice: Proper Shutdown

Opening the door to cool the furnace quickly can cause the refractory ceramic lining to crack from thermal shock. Keeping the door closed during cooldown protects the integrity of the furnace chamber.

How to Apply This to Your Process

Your approach to temperature management should align with your primary objective.

- If your primary focus is accuracy and reproducibility: Leverage a programmable controller to define every stage of the thermal cycle, from ramp rate to cooling period.

- If your primary focus is equipment longevity: Always use a gradual heating ramp, operate well below the furnace's maximum temperature limit, and allow it to cool down with the door closed.

- If your primary focus is operator safety: Never operate the furnace unattended and always be aware of the potential for control system failure.

Mastering your muffle furnace means treating it as a precision instrument, not just a simple oven.

Summary Table:

| Key Aspect | Description |

|---|---|

| Programming | Set target temperature, ramp rate, and hold time using the controller for precise cycles. |

| Monitoring | Continuously check temperature display and ammeter to prevent accidents and ensure proper function. |

| Cooling | Keep door closed post-cycle to avoid thermal shock and moisture damage. |

| Risks | Avoid exceeding temperature limits and rapid heating to protect elements and chamber. |

Upgrade your lab's precision and safety with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Ensure accurate temperature control and long equipment life—contact us today for a tailored solution!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites