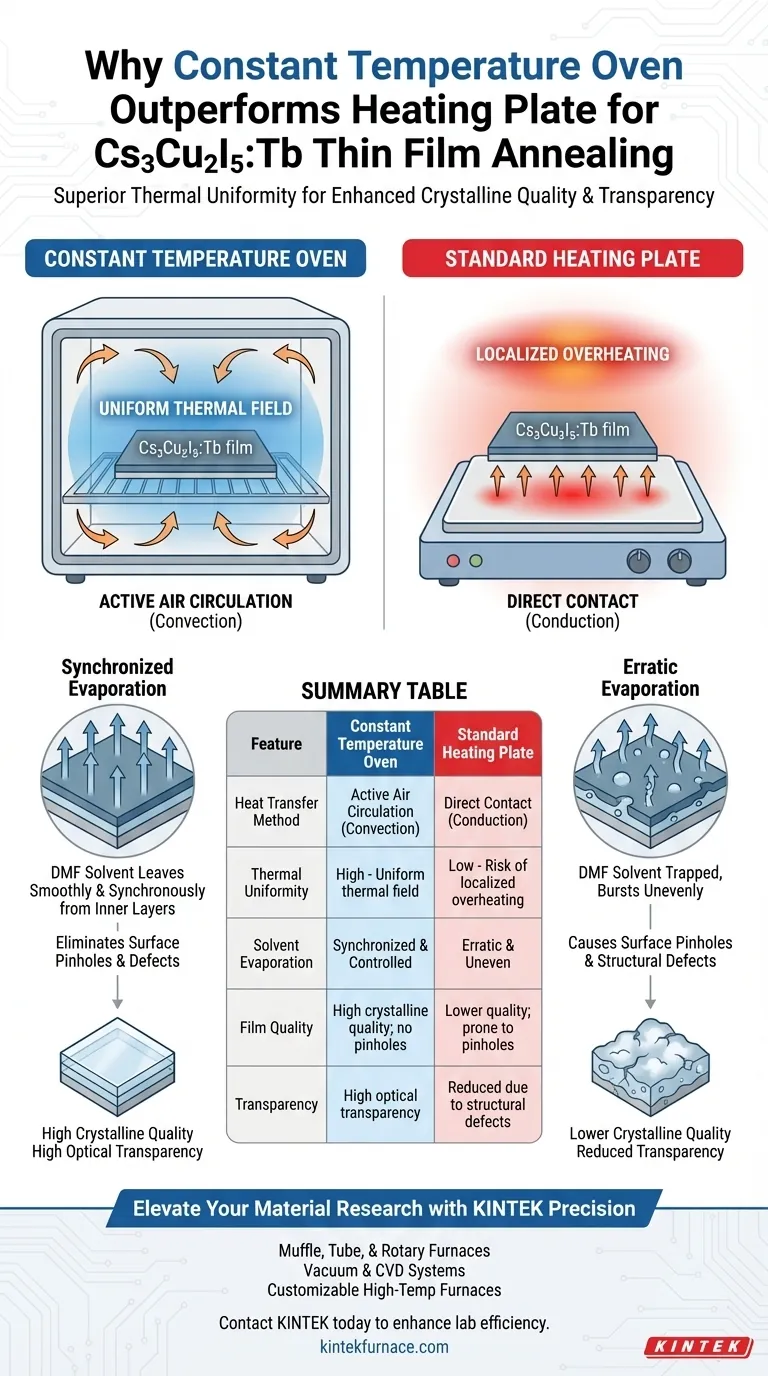

The superiority of a constant temperature oven lies in its ability to create a uniform thermal environment through active air circulation. Unlike a standard heating plate, which risks localized overheating, an oven ensures the synchronized evaporation of the solvent dimethylformamide (DMF) from the film's inner layers. This precise control eliminates surface pinholes, resulting in Cs3Cu2I5:Tb films with significantly higher crystalline quality and optical transparency.

The core difference involves airflow control: constant temperature ovens utilize internal circulation to create a uniform thermal field, whereas heating plates rely on conductive heat that often leads to uneven solvent evaporation and structural defects.

The Mechanism of Thermal Uniformity

To understand why the oven yields better results, you must look at how heat is delivered to the thin film.

The Limitation of Heating Plates

Standard heating plates transfer thermal energy primarily through conduction from the bottom substrate upward.

This method often creates localized overheating spots on the film.

Because the heat is not distributed evenly across the entire environment, the solvent evaporation becomes erratic, leading to physical defects in the material structure.

The Advantage of Internal Air Circulation

A constant temperature oven operates differently by utilizing an internal air circulation system.

This system creates a controlled airflow environment surrounding the entire sample, rather than just heating it from beneath.

The result is a completely uniform thermal field, ensuring that every part of the thin film experiences the exact same temperature and airflow conditions simultaneously.

Optimizing Solvent Evaporation

The critical challenge in annealing Cs3Cu2I5:Tb films is the removal of the solvent, dimethylformamide (DMF). The method of heating dictates how this solvent leaves the film.

Synchronized Evaporation

The uniform environment of the oven promotes synchronized evaporation of the DMF.

This means the solvent is removed from the inner layers of the film at a rate that matches the surface evaporation.

This "rapid" and coordinated removal prevents the solvent from becoming trapped or bursting out unevenly.

Eliminating Surface Defects

When evaporation is not synchronized—as is common with heating plates—pinholes form on the surface of the film.

These pinholes are direct consequences of uneven drying and localized overheating.

By ensuring uniform evaporation, the oven effectively eliminates these surface pinholes, preserving the integrity of the film's surface.

Understanding the Trade-offs

While the constant temperature oven is the superior technical choice for quality, it is important to understand the specific pitfalls of the alternative to appreciate the trade-off.

The Quality Cost of Direct Contact Heating

Choosing a heating plate involves a significant trade-off in final material quality.

While a plate may be simpler to set up, the lack of a controlled atmosphere sacrifices crystalline quality.

Furthermore, the physical defects (pinholes) introduced by the plate significantly reduce the transparency of the final scintillation film, rendering it less effective for optical applications.

Making the Right Choice for Your Goal

The choice of annealing equipment dictates the structural and optical success of your Cs3Cu2I5:Tb thin films.

- If your primary focus is Crystal Structure: Use the constant temperature oven to ensure synchronized evaporation of DMF, which improves the overall crystalline quality of the film.

- If your primary focus is Optical Transparency: Rely on the oven's uniform thermal field to eliminate surface pinholes, which are the main detractors of film transparency.

By replacing localized conduction with a controlled, circulating thermal environment, you ensure the production of defect-free, high-performance scintillation films.

Summary Table:

| Feature | Constant Temperature Oven | Standard Heating Plate |

|---|---|---|

| Heat Transfer Method | Active Air Circulation (Convection) | Direct Contact (Conduction) |

| Thermal Uniformity | High - Uniform thermal field | Low - Risk of localized overheating |

| Solvent Evaporation | Synchronized & controlled | Erratic & uneven |

| Film Quality | High crystalline quality; no pinholes | Lower quality; prone to surface pinholes |

| Transparency | High optical transparency | Reduced due to structural defects |

Elevate Your Material Research with KINTEK Precision

Achieve superior crystalline quality and defect-free thin films with our advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance lab equipment, including:

- Muffle, Tube, & Rotary Furnaces for precise material synthesis.

- Vacuum & CVD Systems for advanced coating applications.

- Customizable High-Temp Furnaces tailored to your unique research needs.

Don't let uneven heating compromise your results. Contact KINTEK today to discover how our high-precision thermal systems can enhance your lab's efficiency and output.

Visual Guide

References

- Haifeng Chen. Study on rare-earth element-doped copper halides. DOI: 10.54254/2977-3903/2025.23781

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does high-temperature calcination functionalize ZnO and KCC-1? Optimize Nanopowder Architecture and Performance

- How are muffle furnaces used in ceramic material processing? Unlock Precision Sintering for High-Performance Ceramics

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What are the primary applications of muffle furnaces in materials research? Unlock Precision in Synthesis and Analysis

- What are some advancements in modern muffle furnace technology? Boost Precision and Efficiency in Your Lab

- What are the temperature capabilities of a lab muffle furnace? Find the Right Heat for Your Lab Needs

- What is the function of a high-precision muffle furnace in plant sample analysis? Achieve Pure Ash for Precise Data