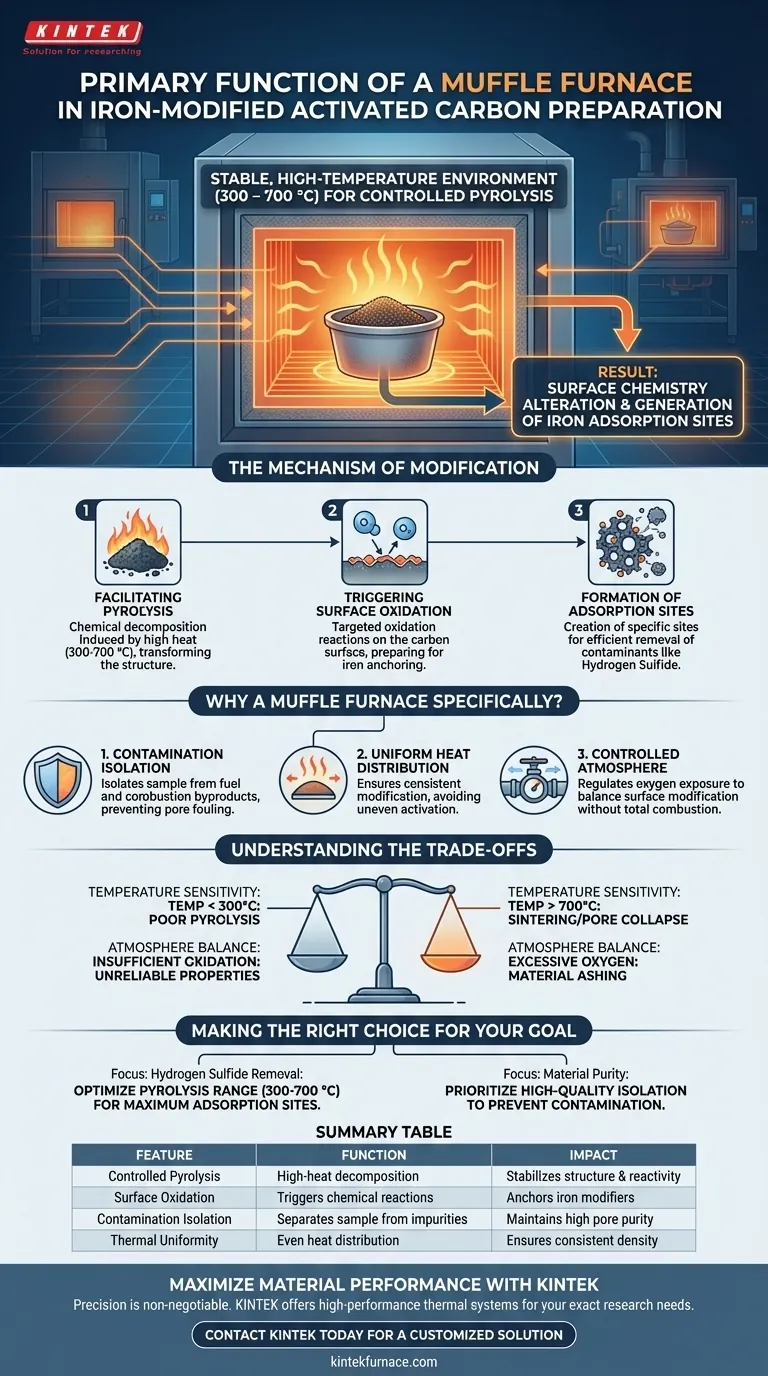

The primary function of a muffle furnace in the preparation of iron-modified activated carbon is to provide a stable, high-temperature environment necessary to execute controlled pyrolysis. By subjecting the material to temperatures strictly between 300 and 700 °C, the furnace facilitates a thermal treatment that fundamentally alters the surface chemistry of the carbon.

The muffle furnace acts as a precision activation chamber. It drives specific oxidation reactions that generate iron adsorption sites, directly enhancing the material’s capacity to remove contaminants like hydrogen sulfide.

The Mechanism of Modification

The effectiveness of iron-modified activated carbon relies on how the iron interacts with the carbon structure. The muffle furnace enables this through three specific mechanisms.

Facilitating Pyrolysis

The core process occurring within the furnace is pyrolysis. This is not simple drying; it is a chemical decomposition induced by high heat.

The furnace must maintain a specific temperature range, typically 300 to 700 °C. This heat input is sufficient to drive the chemical transformation without destroying the underlying carbon structure.

Triggering Surface Oxidation

Heat treatment within the muffle furnace triggers targeted oxidation reactions on the surface of the activated carbon.

This step is critical for modifying the chemical nature of the carbon's surface area. It prepares the substrate to anchor the iron modifier effectively.

Formation of Adsorption Sites

The ultimate goal of this thermal process is the creation of specific iron adsorption sites.

By controlling the heat, the furnace promotes the formation of these sites. This structural change significantly improves the material's efficiency in removing specific pollutants, particularly hydrogen sulfide.

Why a Muffle Furnace Specifically?

While many devices generate heat, a muffle furnace offers specific mechanical advantages required for this delicate chemical process.

Contamination Isolation

A muffle furnace is distinguished by its ability to isolate the sample from the fuel and combustion byproducts.

The heating chamber, often called a "retort," ensures that the activated carbon interacts only with the heat and the controlled atmosphere, not with impurities like soot or burner gases that could foul the adsorption pores.

Uniform Heat Distribution

The furnace utilizes refractory materials to surround the sample, ensuring even heat distribution.

Uniformity is vital. Uneven heating would lead to inconsistent modification, resulting in a batch of activated carbon where some sections are highly active and others remain unmodified.

Controlled Atmosphere

The design allows for the regulation of airflow and oxygen exposure.

While the process requires surface oxidation, uncontrolled exposure to oxygen at these temperatures would simply burn the carbon into ash. The muffle furnace balances this, allowing for chemical modification without total combustion.

Understanding the Trade-offs

Precise control of the muffle furnace is required to avoid compromising the material.

Temperature Sensitivity

Operating outside the 300 to 700 °C window yields poor results.

Temperatures that are too low will fail to trigger the necessary pyrolysis and site formation. Conversely, excessive heat can cause sintering (fusing of particles) or collapse the pore structure, drastically reducing the surface area available for adsorption.

Atmosphere Balance

There is a delicate balance between necessary oxidation and destructive burning.

The "controlled" aspect of the environment is as important as the heat. Insufficient control can lead to inconsistent chemical properties, making the final product unreliable for industrial filtration applications.

Making the Right Choice for Your Goal

When configuring your thermal treatment process, align your furnace settings with your specific performance targets.

- If your primary focus is Hydrogen Sulfide Removal: Ensure your furnace is calibrated to the optimal pyrolysis range (300-700 °C) to maximize the density of iron adsorption sites.

- If your primary focus is Material Purity: Prioritize a muffle furnace with high-quality isolation (retort) integrity to prevent any combustion byproducts from contaminating the carbon pores.

The muffle furnace is not merely a heater; it is the tool that transitions activated carbon from a passive filter into a chemically active, high-performance adsorbent.

Summary Table:

| Feature | Function in Carbon Modification | Impact on Final Product |

|---|---|---|

| Controlled Pyrolysis | High-heat chemical decomposition (300-700 °C) | Stabilizes carbon structure & reactivity |

| Surface Oxidation | Triggers targeted chemical reactions | Anchors iron modifiers effectively |

| Contamination Isolation | Separates samples from fuel/combustion gases | Maintains high pore purity and surface area |

| Thermal Uniformity | Even distribution of heat through refractory materials | Ensures consistent adsorption site density |

Maximize Your Material Performance with KINTEK

Precision is non-negotiable when preparing iron-modified activated carbon. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the exact thermal uniformity and atmosphere control your research demands. Whether you need standard lab equipment or a system fully customizable for unique needs, our high-temp furnaces ensure your pyrolysis and oxidation processes yield superior results.

Ready to upgrade your laboratory capabilities? Contact KINTEK today for a customized solution

Visual Guide

References

- Mayerlin Edith Acunã Montaño, Alesandro Bail. Performance assessment of activated carbon thermally modified with iron in the desulfurization of biogas in a static batch system supported by headspace gas chromatography. DOI: 10.1186/s40543-024-00432-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of high-temperature furnaces in 3D-printed glass debinding? Mastering the Silica Foundation

- What role does an industrial microwave muffle furnace play in the sintering process of porous mullite ceramic skeletons?

- What are the different control types for muffle furnaces? Choose the Right System for Precision and Efficiency

- What is the function of a high-temp muffle furnace in zirconia debinding? Ensure Crack-Free Ceramic Processing

- What heat treatment processes can be performed using Box Furnaces? Master Versatile Thermal Processing

- What are the temperature characteristics of box type electric furnaces? Achieve Precise and Uniform Heating for Your Lab

- What are the environmental requirements for muffle furnace operation? Ensure Safety and Precision in Your Lab

- What are the potential disadvantages of muffle furnaces? Key Trade-offs for Lab Precision