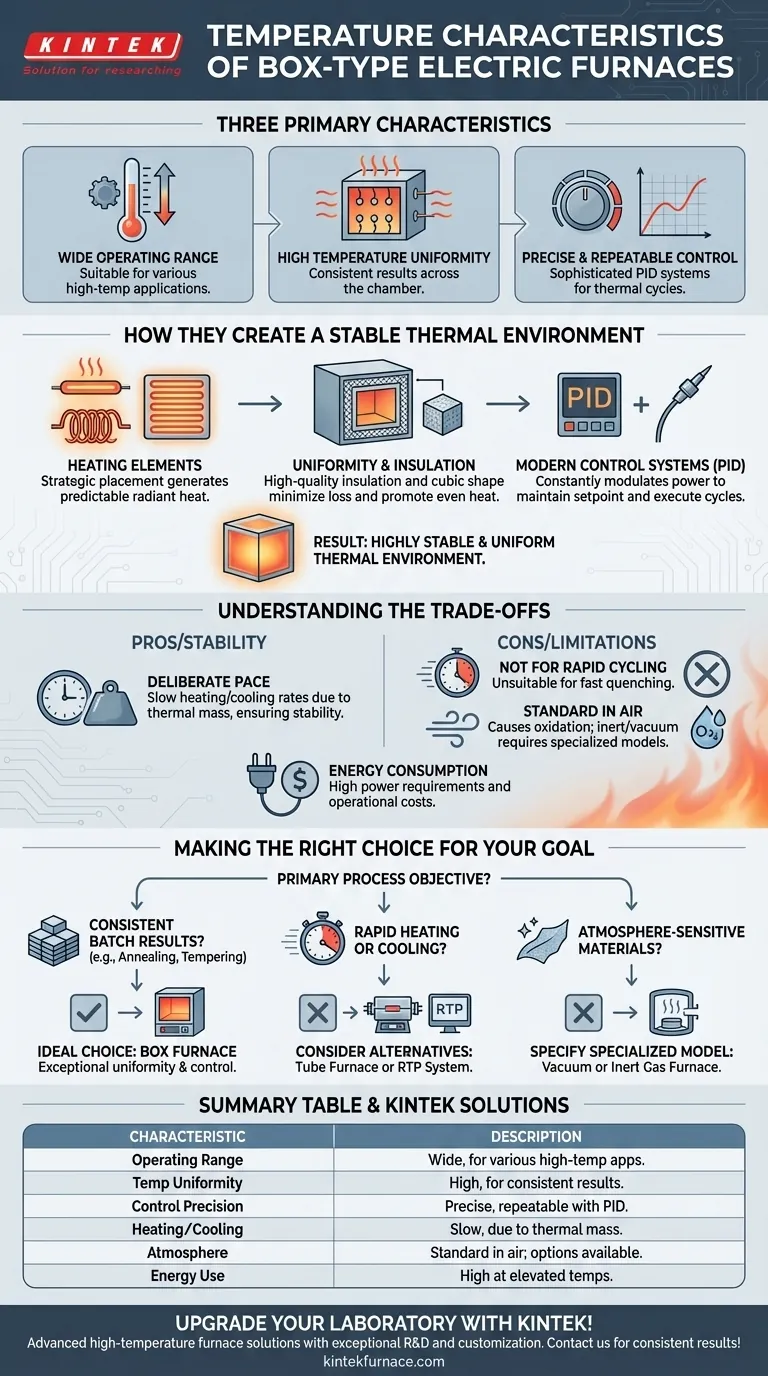

At their core, box-type electric furnaces are defined by three primary temperature characteristics: a wide operating temperature range, high temperature uniformity across the chamber, and precise, repeatable control over the thermal cycle. These attributes are achieved through the strategic design of heating elements and sophisticated electronic control systems.

The true value of a box furnace lies not just in its ability to reach high temperatures, but in its capacity to create a highly stable and uniform thermal environment, which is essential for achieving consistent and reliable results in material processing.

How Box Furnaces Create a Stable Thermal Environment

The temperature characteristics of a box furnace are not accidental; they are the result of deliberate engineering choices in its core components.

The Role of Heating Elements

The foundation of heat generation is the electric heating element. These are most commonly resistance wires, plates, or in some high-temperature applications, graphite rods. When a controlled electric current is passed through them, they generate predictable and stable radiant heat.

The placement of these elements—often on multiple sides of the internal chamber—is critical for initiating uniform heat distribution.

Achieving Temperature Uniformity

True uniformity goes beyond just the heating elements. It is a function of the entire system. High-quality insulation minimizes heat loss to the outside and prevents cold spots within the chamber.

The chamber's cubic design itself helps promote even heat radiation, ensuring that a workpiece placed in the center receives heat consistently from all directions.

The Function of Modern Control Systems

The "brains" of the furnace is its temperature controller, typically a PID (Proportional-Integral-Derivative) controller. This system constantly compares the actual chamber temperature (measured by a thermocouple) to the user's desired setpoint.

It then precisely modulates the power sent to the heating elements to hold the temperature steady, or to execute complex pre-programmed cycles of ramping up, "soaking" at a specific temperature, and cooling down. This enables extremely high process repeatability.

Understanding the Trade-offs

While powerful, the design of a box furnace presents inherent trade-offs that are critical to understand before selecting one for your application.

Slow Heating and Cooling Rates

The same features that ensure stability and uniformity—namely, a large thermal mass and heavy insulation—also mean that box furnaces heat up and cool down slowly. They are not designed for rapid thermal cycling.

This deliberate pace is a trade-off for thermal stability. Processes requiring fast quenching or rapid temperature changes are better suited to different furnace types.

Standard Operation in an Air Atmosphere

A standard box furnace operates with a normal air atmosphere inside the chamber. While suitable for many applications, this can cause oxidation on susceptible materials at high temperatures.

Achieving an inert (e.g., argon, nitrogen) or vacuum atmosphere requires a specialized and significantly more complex furnace with sealed chambers and gas handling systems.

Energy Consumption

Reaching and maintaining high temperatures is an energy-intensive process. The power requirements and operational costs of a box furnace, especially larger models or those running at very high temperatures, are a significant practical consideration.

Making the Right Choice for Your Goal

To determine if a box furnace is the correct tool, you must align its characteristics with your primary process objective.

- If your primary focus is consistent results across batch processes: The exceptional temperature uniformity and repeatable control of a box furnace make it the ideal choice for applications like annealing or tempering.

- If your primary focus is rapid heating or cooling: The slow thermal response of a box furnace makes it unsuitable; consider a smaller tube furnace or a rapid thermal processing (RTP) system instead.

- If your primary focus is processing atmosphere-sensitive materials: A standard box furnace will cause oxidation, so you must specify a model designed for vacuum or inert gas operation.

Ultimately, a box furnace excels at providing a stable, uniform, and controllable heat source for a wide variety of thermal processes.

Summary Table:

| Characteristic | Description |

|---|---|

| Operating Temperature Range | Wide range, suitable for various high-temperature applications |

| Temperature Uniformity | High uniformity across the chamber for consistent results |

| Control Precision | Precise and repeatable thermal cycles using PID controllers |

| Heating/Cooling Rates | Slow rates due to thermal mass, ideal for stable processes |

| Atmosphere | Standard operation in air; inert/vacuum options available |

| Energy Consumption | High energy use, especially at elevated temperatures |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable box furnaces, Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior temperature control and process repeatability. Contact us today to discuss how our furnaces can enhance your material processing efficiency and deliver consistent results!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What role does a Muffle Furnace play in 1100°C oxidation experiments? Precision Thermal Control for Coatings

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics