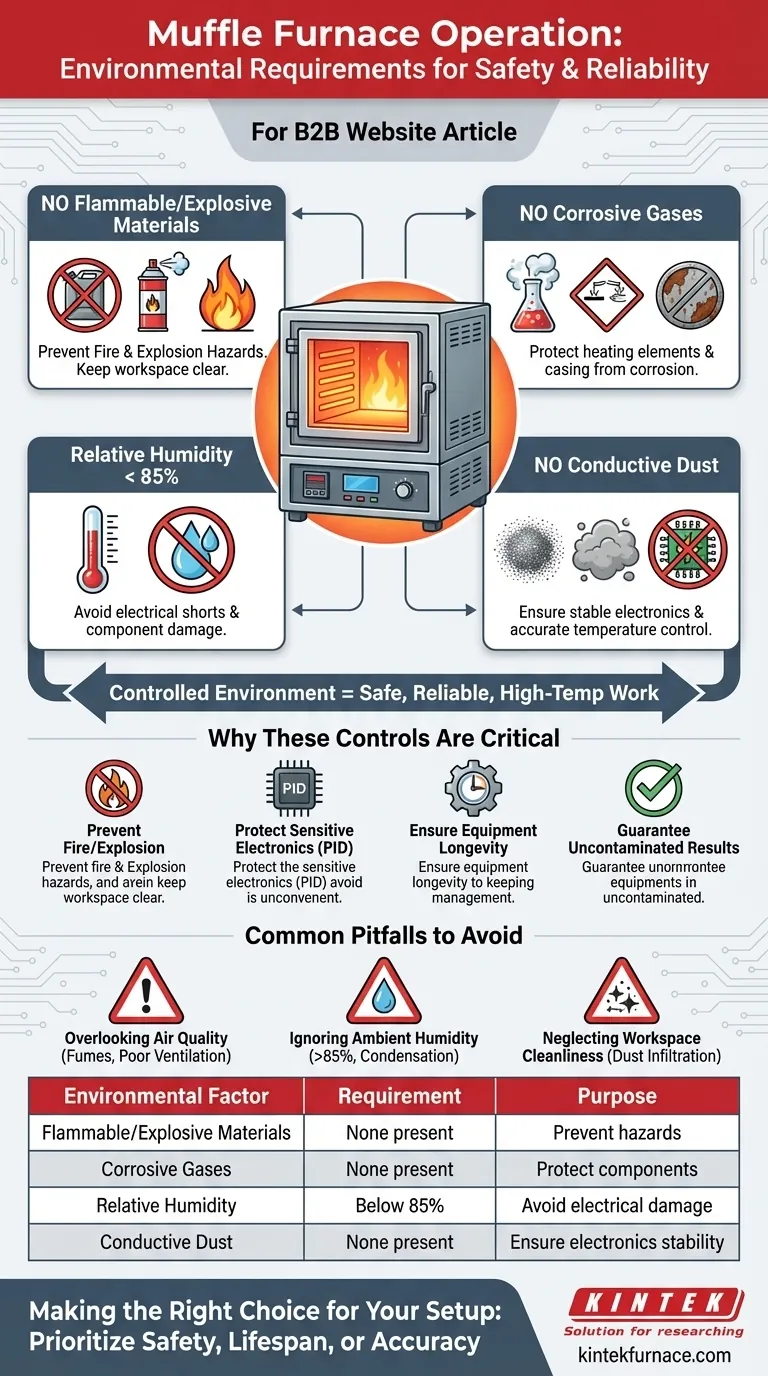

For safe and reliable operation, a muffle furnace must be placed in a controlled environment. The area must be free of flammable materials, explosive substances, and corrosive gases. Furthermore, the relative humidity should be kept below 85%, and there should be no conductive dust present.

A muffle furnace's high operating temperatures and sensitive electronic controls make it highly vulnerable to its surroundings. Meeting its environmental requirements is not just a procedural formality—it is a critical measure for ensuring operator safety, equipment longevity, and the integrity of your results.

Why These Environmental Controls Are Critical

A muffle furnace is a precision instrument that generates extreme heat. Each environmental rule is designed to mitigate a specific risk associated with its operation, protecting the equipment, the user, and the validity of the work being performed.

Preventing Fire and Explosion Hazards

Muffle furnaces can reach temperatures exceeding 1400°C (2550°F).

At these temperatures, any nearby flammable or explosive materials—including certain gases, vapors, liquids, or even fine powders—can ignite instantly, creating a significant fire or explosion risk. A strictly controlled, clear workspace is the first line of defense.

Protecting Sensitive Electronics

Modern furnaces rely on sophisticated digital controllers (like PID controllers) and sensors to maintain precise temperatures.

Conductive dust (e.g., metallic particles) and excessive humidity can cause short circuits in these electronic components. This can lead to equipment malfunction, inaccurate temperature regulation, or complete failure.

Ensuring Equipment Longevity

The integrity of the furnace itself depends on a clean environment.

Corrosive gases in the atmosphere can attack the furnace's heating elements, thermocouple sensors, and even the steel casing over time. High humidity can also accelerate this corrosion and degrade the internal ceramic insulation, reducing thermal efficiency.

Guaranteeing Uncontaminated Results

The core function of a muffle furnace is to heat a material in an isolated chamber, free from contaminants.

While the chamber is sealed, a poorly controlled external environment increases the risk of contamination during sample loading and unloading. A clean, stable environment ensures that the only variables are the ones you are intentionally controlling.

Common Pitfalls in Muffle Furnace Placement

Failing to properly assess the operating environment is a common and costly mistake. Awareness of these oversights is key to preventing them.

Overlooking Air Quality

The term "corrosive gases" is not limited to obvious chemical fumes. Vapors from nearby cleaning processes, poor general ventilation, or even humid coastal air can introduce corrosive agents that degrade the furnace over the long term.

Ignoring Ambient Humidity

Even in an otherwise clean room, high humidity (above 85%) is a silent threat. It can lead to condensation on cool electronic boards when the furnace is off, fostering corrosion and creating a risk of electrical faults when it is powered on.

Neglecting Workspace Cleanliness

"Conductive dust" can be generated by processes you might not immediately associate with the furnace. Nearby grinding, cutting, or even general workshop dust can settle on and infiltrate the furnace’s control housing, creating a hidden failure point.

Making the Right Choice for Your Setup

Your specific priorities will determine which environmental factors demand the most attention.

- If your primary focus is operator safety: Prioritize the absolute removal of all flammable and explosive materials from the entire room, not just the immediate vicinity of the furnace.

- If your primary focus is equipment lifespan: Pay close attention to air quality, ensuring no corrosive agents are present and that relative humidity remains consistently low.

- If your primary focus is result accuracy: Maintain a pristine workspace, free from conductive dust or any airborne contaminants that could compromise the system's electronic stability.

Ultimately, a controlled environment is the foundation for safe, repeatable, and reliable high-temperature work.

Summary Table:

| Environmental Factor | Requirement | Purpose |

|---|---|---|

| Flammable/Explosive Materials | None present | Prevent fire and explosion hazards |

| Corrosive Gases | None present | Protect heating elements and casing from corrosion |

| Relative Humidity | Below 85% | Avoid electrical shorts and component damage |

| Conductive Dust | None present | Ensure stable electronics and accurate temperature control |

Ensure your lab's muffle furnace operates safely and efficiently with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs. Contact us today to discuss how we can enhance your setup with reliable, tailored equipment!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination