At its core, muffle furnace control ranges from simple manual interfaces to highly sophisticated, programmable digital systems. Basic models use digital displays for setting a single temperature, while advanced furnaces employ multi-segment PID controllers with communication ports for automating complex thermal profiles and logging data.

The choice of a control system is not about which is "best," but which is most appropriate for your task. The decision hinges on the level of precision, repeatability, and automation your specific application demands.

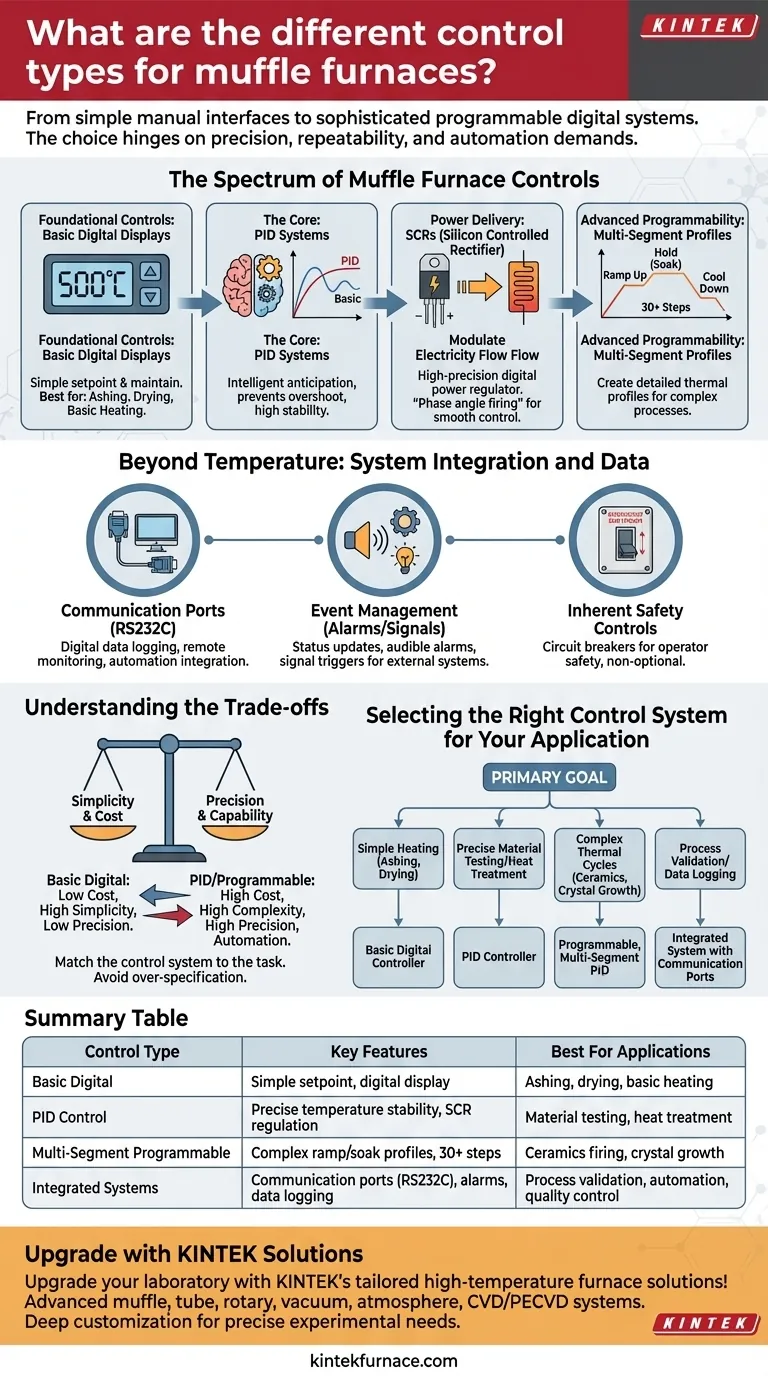

The Spectrum of Muffle Furnace Controls

Understanding the control system is key to leveraging a muffle furnace effectively. The controls dictate not just the temperature you can reach, but how you get there, how long you stay, and how the process is documented.

Foundational Controls: Basic Digital Displays

The simplest control systems consist of an ordinary digital display and a keypad. These are sometimes successors to older analog "pointer tables."

Their function is straightforward: you set a target temperature (setpoint), and the furnace works to reach and maintain it. This is suitable for basic applications where a single, stable temperature is all that's required.

The Core of Modern Control: PID Systems

Most modern, high-quality furnaces use a PID (Proportional-Integral-Derivative) automatic control system. This is the industry standard for precise temperature management.

Think of a PID controller like an advanced cruise control system for your furnace. It doesn't just turn the heat on and off; it intelligently anticipates temperature changes, preventing overshoot and maintaining the setpoint with remarkable stability.

The Power Delivery Mechanism: SCRs

The PID controller is the "brain," but a Silicon Controlled Rectifier (SCR) is often the "muscle." This component acts as a high-precision digital power regulator.

Directed by the PID controller, the SCR finely modulates the amount of electricity flowing to the heating elements. This "phase angle firing" is what allows for the smooth and stable temperature control that PID systems are known for.

Advanced Programmability: Multi-Segment Profiles

For complex processes, a simple setpoint is not enough. Advanced controllers offer multi-segment programmability, often with 30 or more steps.

This allows you to create a detailed thermal profile. You can program the furnace to ramp up to a specific temperature over 30 minutes, hold (or "soak") at that temperature for two hours, cool to a lower temperature, and so on. This is critical for materials science, ceramics, and complex heat treatments.

Beyond Temperature: System Integration and Data

Modern furnace control extends beyond simple heating to include automation, data logging, and safety integration. These features transform the furnace from a standalone box into part of a larger, controlled process.

Data and Automation: Communication Ports

Many advanced controllers include communication terminals like RS232C or other external adapters.

These ports allow the furnace to be connected to a computer or a larger lab automation system. This is essential for digital data logging, remote process monitoring, and integrating the furnace's operation into an automated workflow.

Event Management: Alarms and Signal Outputs

Terminals for alarms, operation signals, and events provide critical status updates to external systems or operators.

These outputs can trigger an audible alarm when a cycle is complete, turn on a light to indicate the furnace is running, or send a signal to another piece of equipment to begin the next step in a process.

Inherent Safety Controls

Beyond process control, every furnace has critical safety controls. The most fundamental is the circuit breaker, which provides an immediate method for emergency power shutdown. These systems are non-optional and essential for operator safety.

Understanding the Trade-offs

Choosing the right features requires balancing capability against complexity and cost.

Simplicity vs. Precision

A basic digital controller is intuitive and reliable for simple tasks like ashing or drying. However, it lacks the stability of a PID system and cannot perform the complex ramp/soak profiles needed for advanced materials work.

Cost vs. Capability

Programmable, multi-segment controllers with communication ports significantly increase a furnace's cost. This investment is justified only when your work requires high precision, automation for repeatability, or data logging for process validation and quality control.

The Risk of Over-Specification

Do not assume more features are always better. An overly complex control system for a simple, repetitive task can introduce unnecessary points of failure and increase training time for operators. Match the control system to the task.

Selecting the Right Control System for Your Application

Use your primary goal to guide your choice of a control system.

- If your primary focus is simple heating to a single temperature (e.g., ashing, drying): A basic digital controller is sufficient and cost-effective.

- If your primary focus is precise material testing or heat treatment: A PID controller is non-negotiable to ensure temperature stability and avoid overshoot.

- If your primary focus is creating complex thermal cycles (e.g., crystal growth, ceramics firing): A programmable, multi-segment PID controller is essential.

- If your primary focus is process validation or data logging for quality control: A system with communication ports (like RS232C) for external data capture is required.

Choosing the right controls ensures your furnace is not just a heat source, but a precise tool tailored to your specific scientific or industrial goal.

Summary Table:

| Control Type | Key Features | Best For Applications |

|---|---|---|

| Basic Digital | Simple setpoint, digital display | Ashing, drying, basic heating |

| PID Control | Precise temperature stability, SCR power regulation | Material testing, heat treatment |

| Multi-Segment Programmable | Complex ramp/soak profiles, 30+ steps | Ceramics firing, crystal growth |

| Integrated Systems | Communication ports (e.g., RS232C), alarms, data logging | Process validation, automation, quality control |

Upgrade your laboratory with KINTEK's tailored high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing precision, repeatability, and efficiency. Contact us today to discuss how our solutions can optimize your processes and drive success!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites