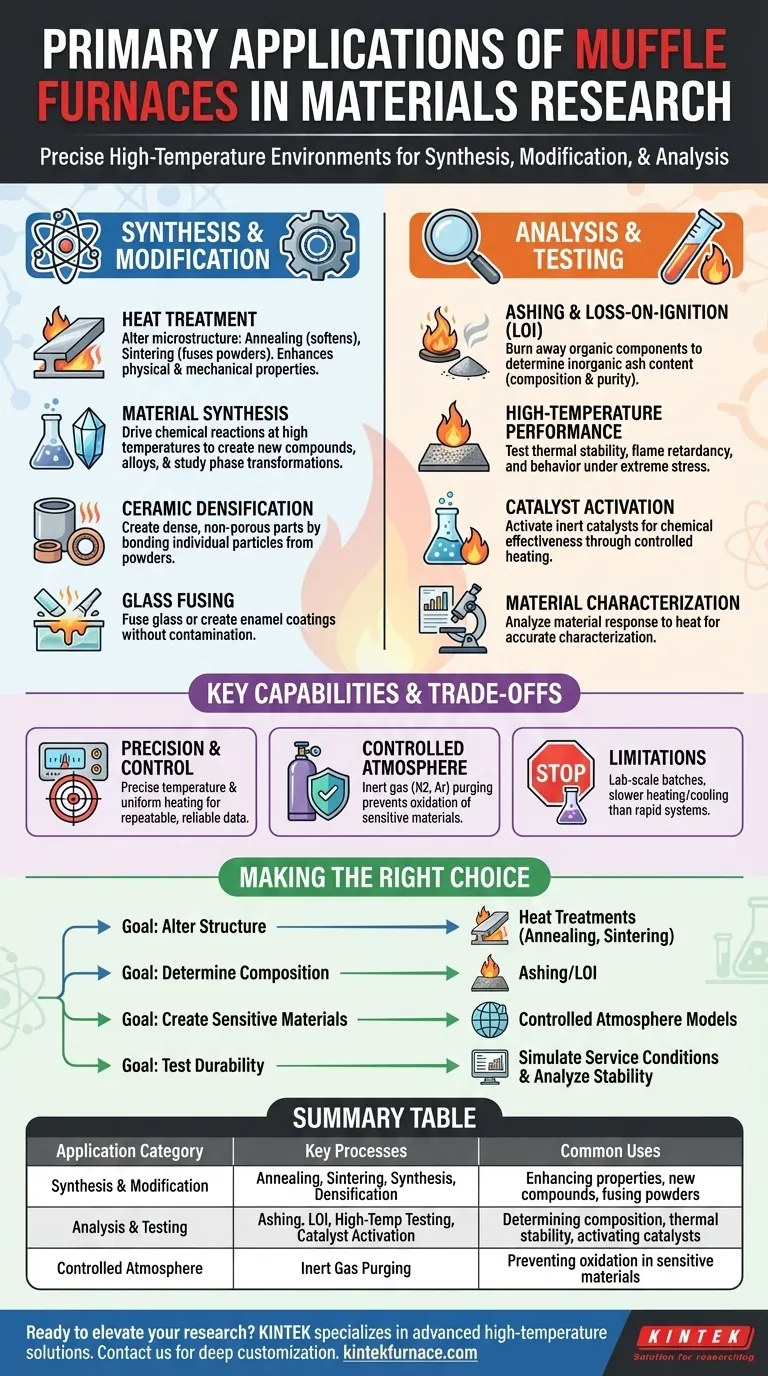

At their core, muffle furnaces are indispensable tools in materials research for one fundamental reason: they provide an extremely precise and uniform high-temperature environment. This controlled heating allows researchers to systematically alter a material's properties, synthesize new compounds, or analyze a sample's composition and thermal stability. Their primary applications fall into two main categories: changing a material's structure and analyzing its response to heat.

The true value of a muffle furnace in research is not just its ability to get hot, but its capacity to do so with precision. This enables the two foundational pillars of materials science: the controlled synthesis and modification of materials, and the rigorous analysis and testing of their properties.

The Core Function: Synthesis and Modification

The primary goal of many research projects is to create a material with specific, desirable properties. Muffle furnaces are the workhorses for achieving this through controlled thermal processing.

Heat Treatment for Property Enhancement

Heat treatment is the process of heating and cooling materials to alter their microstructure. This directly changes their physical and mechanical properties.

Common processes include annealing, which softens metals and relieves internal stresses, and sintering, which fuses powders into a solid mass to increase density and strength, particularly for ceramics and powdered metals.

Material Synthesis and Phase Transformation

Many advanced materials are synthesized at high temperatures. A muffle furnace provides the stable thermal energy needed to drive chemical reactions and create new compounds or alloys.

It is also used to study phase transformations, where a material changes its crystal structure, fundamentally altering its properties. This is critical in the development of shape-memory alloys and advanced ceramics.

Ceramic Densification and Glass Fusing

Muffle furnaces are essential for creating dense, non-porous ceramic parts from powders. The high, uniform heat causes the individual particles to bond and compact.

Similarly, they are used for fusing pieces of glass or creating enamel coatings on metal substrates, relying on the furnace's ability to melt the material without contamination.

The Core Function: Analysis and Testing

Beyond creating materials, researchers must be able to accurately characterize them. Muffle furnaces enable several key analytical techniques that rely on heat.

Ashing and Loss-on-Ignition (LOI)

This is one of the most common applications. A sample is heated to a temperature where all organic and volatile components burn away, leaving only the inorganic, non-combustible residue (ash).

This process is used to determine the ash content in materials like polymers, coal, or biological samples, which is a critical measure of composition and purity.

High-Temperature Performance Testing

Researchers use muffle furnaces to test how a material will behave under extreme thermal stress. This is crucial for industries like aerospace, where components must withstand incredible heat.

Applications include testing the flame retardancy of composites or analyzing the thermal degradation and stability of polymers and plastics.

Catalyst Activation

Many catalysts are inert at room temperature and require a high-temperature "activation" step to become chemically effective. A muffle furnace provides the controlled environment needed to prepare these catalysts for use in chemical reactions.

Key Capabilities and Trade-offs

A muffle furnace is chosen for specific reasons, but it's important to understand its limitations.

The Power of Precision and Control

The defining feature of a research-grade muffle furnace is its precise temperature control. This allows for highly repeatable experiments, which is the bedrock of reliable scientific data.

The "muffle"—an insulating shell separating the heating elements from the chamber—ensures uniform heating, preventing hot spots that could compromise the sample or experiment.

The Advantage of a Controlled Atmosphere

Many advanced materials, particularly metals and certain alloys, will oxidize or react with air at high temperatures.

More advanced muffle furnaces can be purged with an inert gas (like nitrogen or argon), creating a low-oxygen environment that protects sensitive samples from unwanted chemical reactions.

Understanding the Limitations

Muffle furnaces are designed for lab-scale batches, not large-scale industrial production.

While precise, their heating and cooling rates can be slower than highly specialized equipment like rapid thermal processing (RTP) systems. For applications requiring near-instant temperature changes, a different tool may be necessary.

Making the Right Choice for Your Goal

To apply this effectively, match the furnace's capability to your research objective.

- If your primary focus is altering a material's internal structure: Use the furnace for heat treatments like annealing and sintering to improve mechanical properties.

- If your primary focus is determining material composition: Use the furnace for ashing or loss-on-ignition to precisely quantify the inorganic content.

- If your primary focus is creating new or sensitive materials: Use a model with controlled atmosphere capabilities to prevent oxidation during synthesis.

- If your primary focus is testing material durability: Use the furnace to simulate high-temperature service conditions and analyze thermal stability or flame retardancy.

Ultimately, the muffle furnace serves as a foundational tool, empowering researchers to precisely manipulate and measure the very essence of their materials.

Summary Table:

| Application Category | Key Processes | Common Uses |

|---|---|---|

| Synthesis and Modification | Annealing, Sintering, Material Synthesis, Ceramic Densification | Enhancing material properties, creating new compounds, fusing powders |

| Analysis and Testing | Ashing, Loss-on-Ignition, High-Temperature Testing, Catalyst Activation | Determining composition, testing thermal stability, activating catalysts |

| Controlled Atmosphere | Inert Gas Purging | Preventing oxidation in sensitive materials like metals and alloys |

Ready to elevate your materials research with precision high-temperature solutions? KINTEK specializes in advanced muffle furnaces and other high-temperature systems like Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring accurate synthesis, analysis, and testing for diverse laboratories. Contact us today to discuss how our tailored solutions can enhance your research outcomes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production