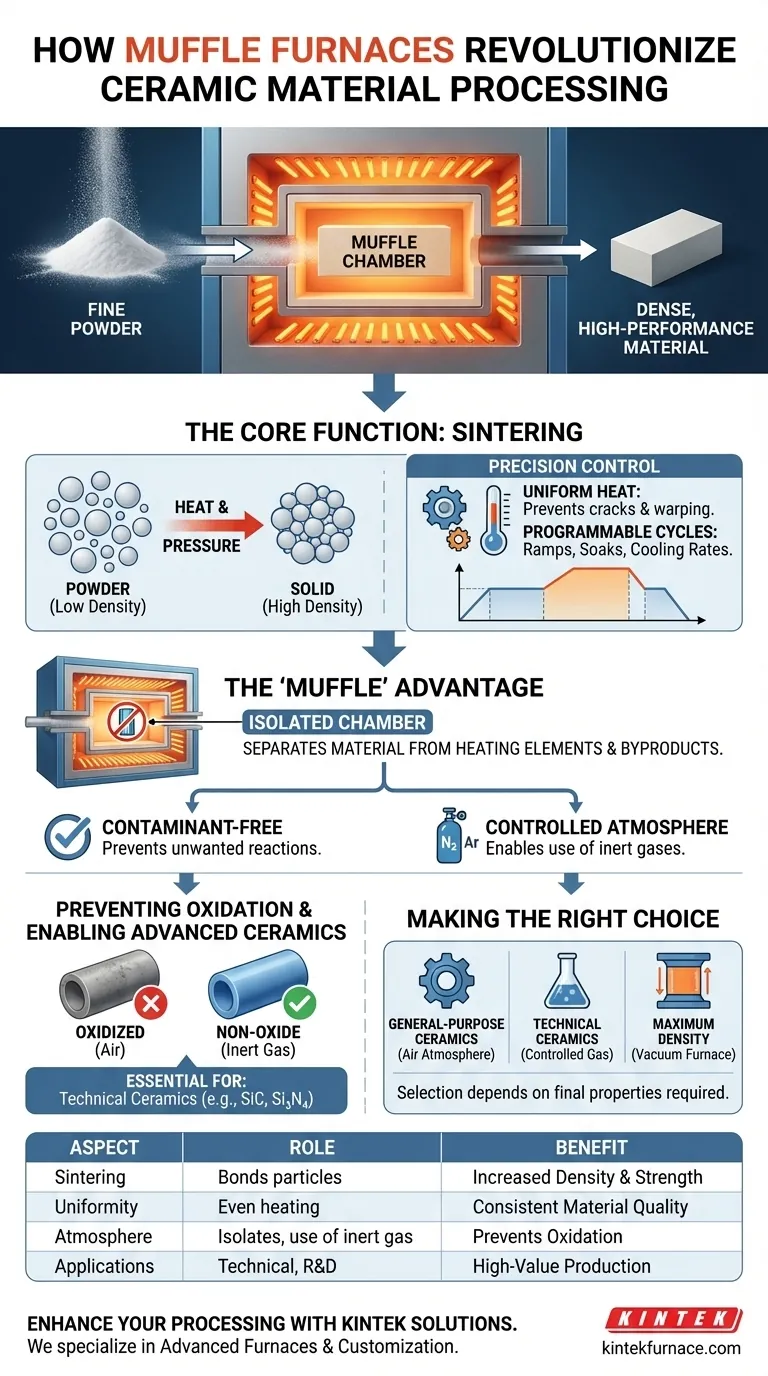

In ceramic processing, muffle furnaces are the definitive tool for transforming fine powders into dense, solid, high-performance materials. They achieve this through the process of sintering, which requires the precise application of high temperatures within a strictly controlled environment. This control over heat and atmosphere is what allows engineers to dictate the final properties of the ceramic, such as its hardness, density, and thermal resistance.

The core value of a muffle furnace is not just its ability to get hot, but its capacity to provide a pristine and highly controlled environment. This isolates the ceramic material from contaminants and unwanted chemical reactions, ensuring the finished product achieves its designed engineering properties.

The Core Function: From Powder to Solid

The primary use of a muffle furnace in ceramics is to execute the sintering process with exceptional precision. This involves more than simply heating the material.

What is Sintering?

Sintering is a thermal treatment process that bonds ceramic particles together at temperatures below their melting point. Instead of melting and re-solidifying, the atoms in the particles diffuse across the boundaries, fusing them into a solid, coherent mass. This reduces porosity and significantly increases the material's density and strength.

The Role of Uniform Heat

Muffle furnaces are engineered to provide exceptional temperature uniformity through a combination of radiative and convective heat transfer. This ensures that the entire ceramic component heats and cools at the same rate, preventing internal stresses, cracks, or warping that would result from uneven temperatures.

Precision Temperature Control

Achieving specific material properties depends on a precise heating and cooling profile. Muffle furnaces allow operators to program controlled ramp rates (how fast the temperature rises), soak times (how long it stays at a peak temperature), and cooling rates. This cycle is critical for developing the desired crystalline structure and density.

Why the "Muffle" is Critical

The term "muffle" refers to the furnace's core design feature: an isolated inner chamber that separates the material being processed from the heating elements and any combustion byproducts.

Isolating from Contaminants

In a direct-fired furnace, byproducts from fuel combustion can contaminate the material, leading to discoloration or undesirable chemical changes. The muffle acts as a physical barrier, ensuring the atmosphere surrounding the ceramic is pure and consists only of the intended gases.

Enabling Controlled Atmospheres

Because the muffle is a sealed chamber, the atmosphere inside can be carefully managed. The air can be purged and replaced with a specific gas, such as nitrogen or argon. This capability is fundamental for processing advanced, non-oxide ceramics.

Preventing Oxidation

Many high-performance technical ceramics, like silicon carbide (SiC) or silicon nitride (Si₃N₄), will readily oxidize at high temperatures if exposed to oxygen. A controlled atmosphere of inert gas like nitrogen prevents these unwanted reactions, preserving the material's chemical integrity and ensuring it meets performance specifications for aerospace or biomedical applications.

Understanding the Trade-offs and Alternatives

While powerful, a standard muffle furnace is part of a broader family of high-temperature processing tools. Understanding the distinctions is key to selecting the right process.

Atmosphere vs. Vacuum: A Key Distinction

For the highest-purity applications, a vacuum furnace is often used. Instead of replacing the air with an inert gas, a vacuum furnace removes nearly all atmospheric gases. This is the ultimate method for minimizing porosity and preventing any atmospheric reactions, helping produce ceramics with near-theoretical density and superior mechanical strength.

Limitations and Considerations

Muffle furnaces are typically used for batch processing, which can influence production throughput compared to continuous heating methods. Their cycle times, which include controlled heating and cooling ramps, can be lengthy, making them ideal for research, development, and the production of high-value components rather than high-volume, low-cost items.

Versatility Beyond Ceramics

The same principles of thermal control and atmospheric isolation make muffle furnaces essential in other fields. They are used for the annealing of semiconductor wafers, heat-treating metals like steel and copper, and analytical processes like ashing samples in a lab.

Making the Right Choice for Your Goal

The ideal furnace configuration depends directly on the final properties your material requires. The choice between air, a controlled gas atmosphere, or a vacuum is the most critical decision.

- If your primary focus is general-purpose ceramics or oxide-based materials: A standard muffle furnace with precise temperature control in an air atmosphere is often sufficient.

- If your primary focus is developing high-performance technical ceramics (like SiC or Si₃N₄): A furnace with advanced atmospheric controls (like nitrogen or argon) is essential to prevent oxidation.

- If your primary focus is achieving maximum density and purity for extreme applications: A vacuum furnace is the superior choice, as it provides the cleanest possible processing environment.

Ultimately, mastering the furnace environment is the key to mastering the final properties of your ceramic material.

Summary Table:

| Aspect | Role in Ceramic Processing |

|---|---|

| Sintering | Bonds ceramic particles at high temperatures to increase density and strength without melting. |

| Temperature Uniformity | Ensures even heating to prevent cracks and warping for consistent material quality. |

| Atmosphere Control | Isolates ceramics from contaminants and enables inert gas use to prevent oxidation. |

| Applications | Ideal for technical ceramics, annealing, and ashing in research and high-value production. |

Ready to enhance your ceramic material processing with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs precisely. Contact us today to discuss how our expertise can optimize your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO