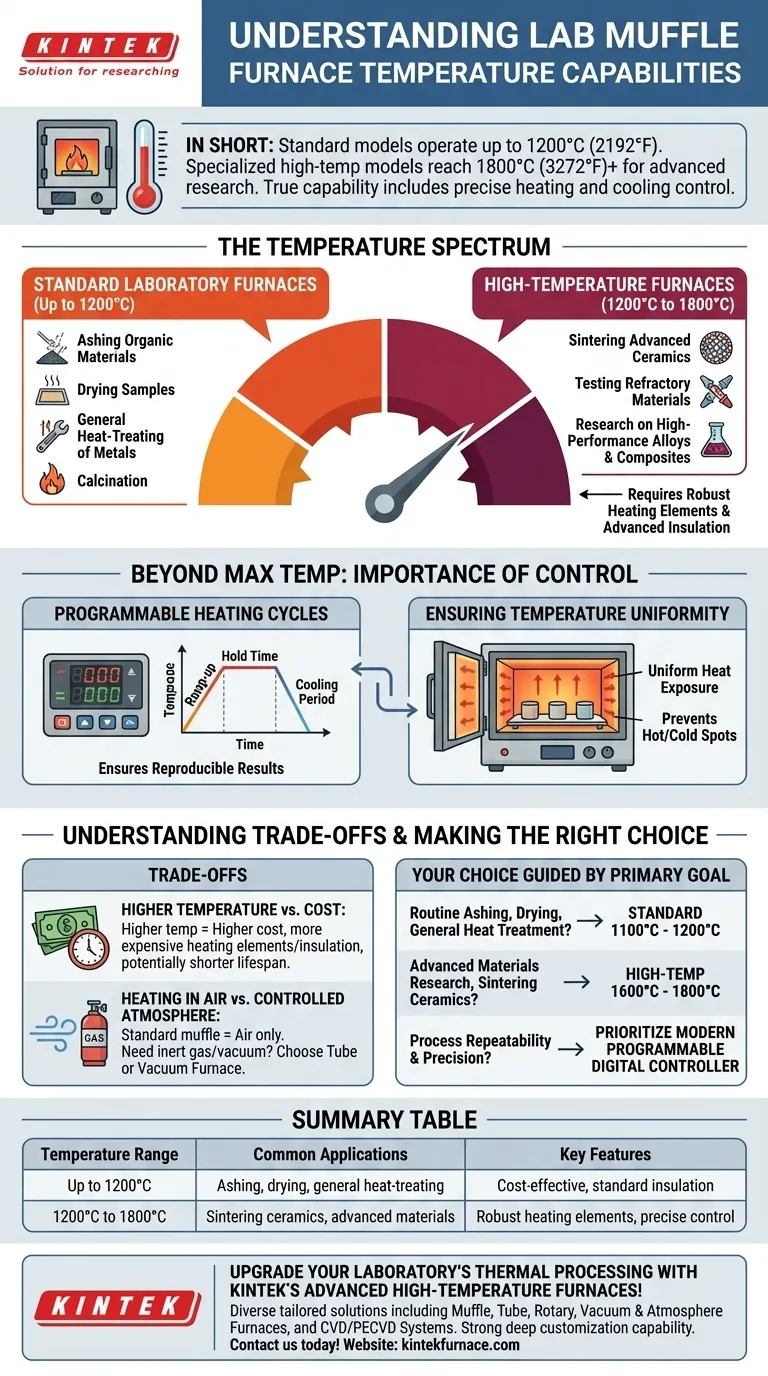

In short, a standard lab muffle furnace typically operates up to 1200°C (2192°F), which is sufficient for most common applications. However, specialized high-temperature models are widely available and can achieve working temperatures of 1800°C (3272°F) or even higher for advanced materials science and research.

The true capability of a muffle furnace is defined not just by its maximum temperature, but by its ability to precisely control the entire heating and cooling cycle. This control is what ensures accurate, repeatable results for sensitive thermal processes.

Understanding the Temperature Spectrum

A muffle furnace is not a one-size-fits-all device. Its temperature capabilities are directly tied to its intended application, which is reflected in its construction and cost.

Standard Laboratory Furnaces (Up to 1200°C)

These are the workhorses of most labs, designed for common thermal processes.

They are ideal for applications like ashing organic materials, drying samples, general heat-treating of metals, and calcination.

Their temperature range of roughly 100°C to 1200°C covers the vast majority of routine testing and preparation procedures.

High-Temperature Furnaces (1200°C to 1800°C)

These furnaces are built for more demanding, specialized tasks that require extreme heat.

They are essential for sintering advanced ceramics, testing refractory materials, and conducting research on high-performance alloys and composites.

Reaching these temperatures requires more robust heating elements and advanced insulation, making these units significantly more specialized.

Beyond Maximum Temperature: The Importance of Control

Simply reaching a high temperature is not enough. The value of a modern muffle furnace lies in its ability to manage the thermal profile with precision.

Programmable Heating Cycles

Modern furnaces use digital controllers that allow users to program specific heating cycles.

This includes setting the ramp-up rate (how quickly the temperature rises), the hold time (how long it stays at a target temperature), and the cooling period.

This level of automation is critical for ensuring that results are reproducible between different runs and different users.

Ensuring Temperature Uniformity

The core design of a muffle furnace, where the heating elements are outside the "muffle" or internal chamber, promotes excellent temperature uniformity.

This ensures that the entire sample is exposed to the same temperature, preventing inconsistent results caused by hot or cold spots within the chamber.

Understanding the Trade-offs

Selecting a furnace requires balancing performance needs with practical constraints. A higher maximum temperature is not always the best choice.

Higher Temperature vs. Cost

Furnaces capable of reaching 1600°C to 1800°C are significantly more expensive than standard 1200°C models.

The heating elements and insulation required for these extreme temperatures are costly and may have a shorter operational lifespan, leading to higher maintenance costs.

Heating in Air vs. Controlled Atmosphere

A standard muffle furnace is designed to heat samples in an ambient air atmosphere.

If your process requires a specific inert gas environment (like nitrogen or argon) or a vacuum, a standard muffle furnace is not the correct tool. In those cases, a specialized tube furnace or vacuum furnace is necessary.

Making the Right Choice for Your Application

Use your primary goal to guide your selection.

- If your primary focus is routine ashing, drying, or general heat treatment: A standard furnace reaching 1100°C to 1200°C is sufficient and cost-effective.

- If your primary focus is advanced materials research or sintering ceramics: You will need a high-temperature model capable of reaching 1600°C to 1800°C.

- If your primary focus is process repeatability and precision: Prioritize a furnace with a modern, programmable digital controller over raw maximum temperature.

Choosing the right muffle furnace is about matching its precise thermal capabilities to the specific demands of your process.

Summary Table:

| Temperature Range | Common Applications | Key Features |

|---|---|---|

| Up to 1200°C | Ashing, drying, general heat-treating | Cost-effective, standard insulation |

| 1200°C to 1800°C | Sintering ceramics, advanced materials research | Robust heating elements, precise control |

Upgrade your laboratory's thermal processing with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met precisely. Contact us today to discuss how our furnaces can enhance your precision and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment