At its core, a muffle furnace ensures contamination-free heating through physical isolation. It achieves this by using a separate, sealed inner chamber—the "muffle"—that encloses the sample. This design creates a barrier between your material and the furnace's heat source, preventing any direct contact or transfer of unwanted substances.

The fundamental advantage of a muffle furnace is not just its ability to reach high temperatures, but its capacity to do so without compromising the chemical integrity of the sample. By separating the material from combustion gases and the external environment, it preserves the purity required for accurate analysis and processing.

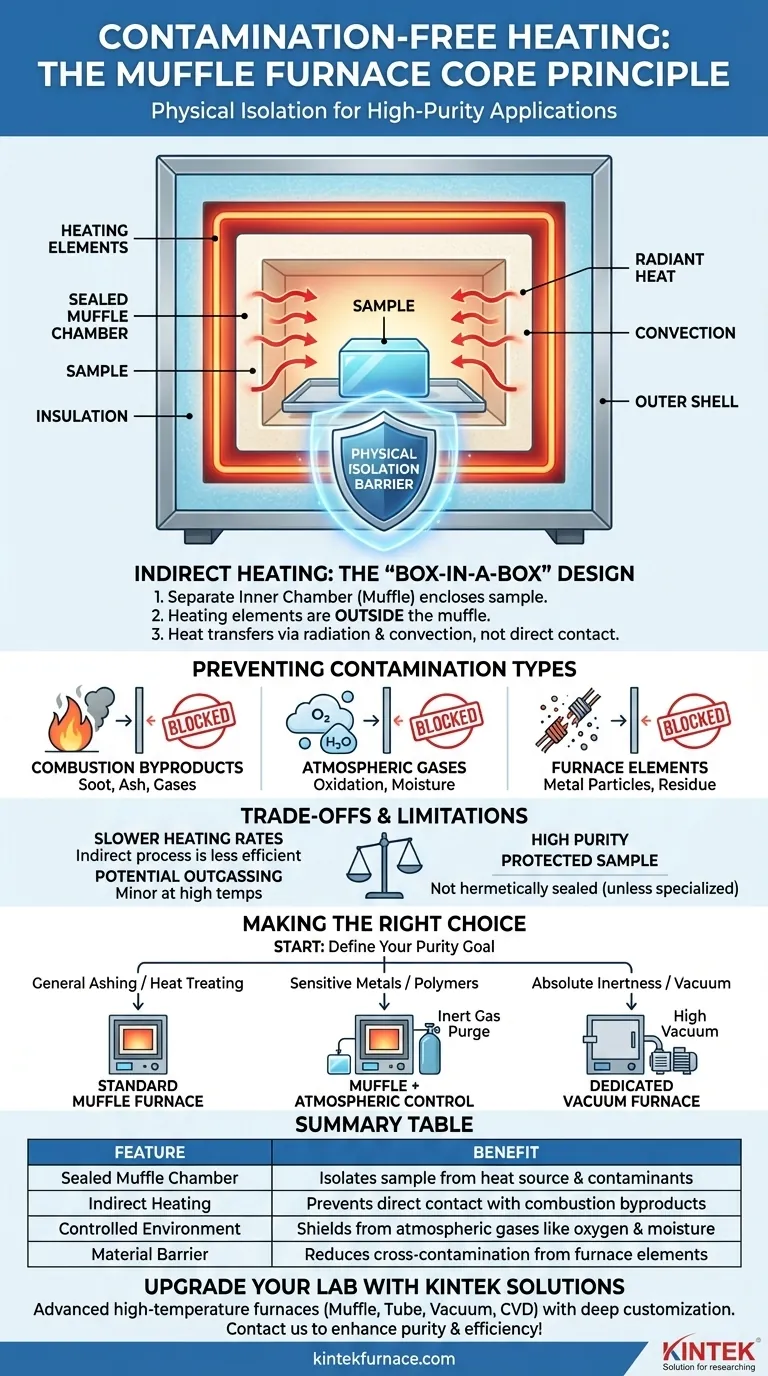

The Core Principle: Indirect Heating

The design of a muffle furnace is intentionally simple but highly effective. It operates on the principle of indirect heating, which is the key to its contamination-free performance.

The Role of the Muffle Chamber

The term "muffle" refers to an insulated, enclosed chamber, typically made of high-temperature-resistant ceramic or alloy. Your sample is placed inside this box. The furnace's heating elements are located on the outside of the muffle.

This "box-in-a-box" structure is the defining feature of the furnace.

Separating Heat Source from Sample

Because the heating elements or flames never touch the sample, any byproducts are kept separate. The elements heat the muffle's exterior, and that heat is then transferred to the interior via radiation and convection.

This process ensures that contaminants like combustion gases, fuel residues, or particles from the heating elements themselves cannot reach your sample.

Ensuring a Controlled Environment

The enclosed muffle also shields the sample from the external atmosphere. This isolation prevents unwanted reactions like oxidation or carbonization that can occur when sensitive materials are heated in the open air.

Types of Contamination a Muffle Furnace Prevents

The isolation provided by the muffle design is effective against several common sources of contamination in high-temperature applications.

Contamination from Combustion

In fuel-fired furnaces, the primary concern is contamination from combustion byproducts. These include soot, ash, and various gases that can react with or deposit on the sample, altering its composition.

A muffle furnace completely physically separates the combustion area from the heating chamber, eliminating this risk.

Contamination from the Atmosphere

For many processes, ambient air is a contaminant. The oxygen and moisture present can cause undesirable oxidation on metals or other materials.

The sealed nature of the muffle minimizes the introduction of atmospheric gases, protecting the sample's surface integrity. For even greater control, some models allow for the introduction of an inert gas.

Contamination from the Furnace Itself

In direct-heating electric furnaces, material can degrade from the heating elements and deposit onto the sample. The muffle acts as a durable, inert barrier, preventing this form of cross-contamination.

Understanding the Trade-offs and Limitations

While highly effective, it's important to recognize that a muffle furnace is not a perfect solution for every scenario. Understanding its limitations is key to using it correctly.

Slower Heating Rates

Indirect heating is inherently less efficient than direct heating. It takes time for the muffle to absorb heat and then radiate it to the sample, resulting in slower ramp-up times compared to a kiln where the flame directly touches the material.

Standard Models Are Not Hermetically Sealed

A standard muffle furnace provides excellent protection but is not a true hermetically sealed system. For applications requiring a complete vacuum or an ultra-high-purity inert atmosphere, a specialized vacuum or glovebox furnace is necessary.

Potential for Outgassing

At very high temperatures, the muffle material itself or trace contaminants on the sample or chamber walls can "outgas," releasing small amounts of vapor. This is generally a minor concern but can be a factor in ultra-sensitive analytical work.

Making the Right Choice for Your Application

Selecting the right heating method depends entirely on your specific goals for purity, speed, and atmospheric control.

- If your primary focus is general ashing or heat treating: A standard muffle furnace is the ideal choice to prevent contamination from fuel and the atmosphere.

- If your primary focus is processing sensitive metals or polymers: Consider a muffle furnace with an atmospheric control port to purge oxygen with an inert gas like argon or nitrogen.

- If your primary focus requires absolute inertness or a vacuum: A muffle furnace is a good first step, but a dedicated vacuum furnace is the correct tool for the highest level of purity.

By understanding its core principle of isolation, you can confidently leverage the muffle furnace to protect the integrity of your most critical work.

Summary Table:

| Feature | Benefit |

|---|---|

| Sealed Muffle Chamber | Isolates sample from heat source and contaminants |

| Indirect Heating | Prevents direct contact with combustion byproducts |

| Controlled Environment | Shields from atmospheric gases like oxygen and moisture |

| Material Barrier | Reduces cross-contamination from furnace elements |

Upgrade your lab with contamination-free heating solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs. Contact us today to enhance purity and efficiency in your processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO