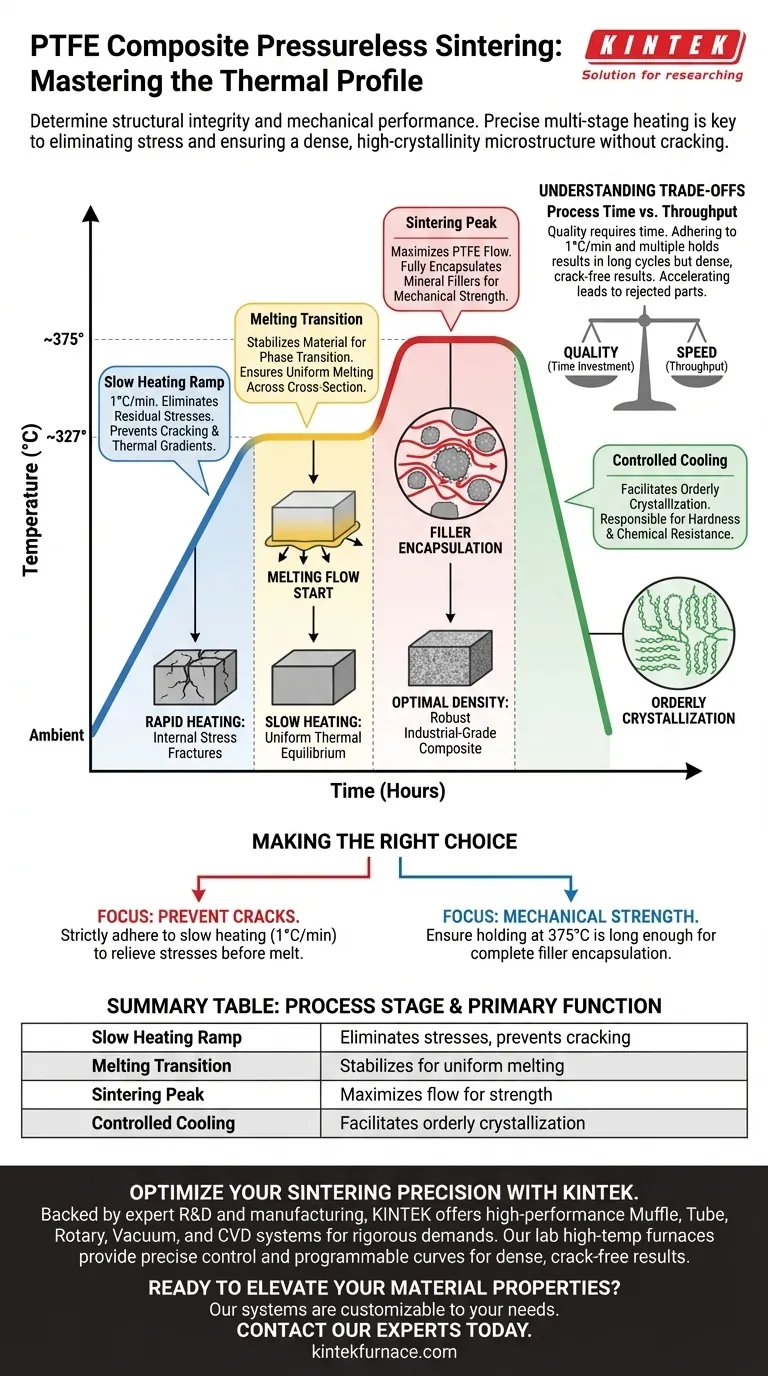

The specific heating and holding curves determine the structural integrity and mechanical performance of your final composite. In pressureless sintering within a box resistance or muffle furnace, this thermal profile dictates how effectively the PTFE matrix flows to encapsulate mineral fillers. A precise, multi-stage program is the only mechanism available to eliminate internal stresses and ensure a dense, high-crystallinity microstructure without cracking.

Precise temperature control—specifically holding near the 327°C melting point and the 375°C sintering peak—is essential for fully encapsulating fillers and managing crystallization. Without a slow, staged heating rate, the composite risks internal stress fractures and poor density.

Controlling Thermal Stress and Cracking

The Necessity of a Slow Heating Rate

To prevent structural failure, you must utilize a slow heating rate, typically around 1°C per minute.

Rapid heating induces thermal gradients that the material cannot absorb uniformly. This slow ramp is critical for eliminating residual internal stresses that inevitably accumulate during the initial molding or compaction phases.

Prevention of Macroscopic Defects

By adhering to a gradual temperature increase, you ensure the material reaches thermal equilibrium layer by layer.

This prevents the formation of cracks and fissures that occur when the exterior expands or changes phase significantly faster than the core.

The Function of Multi-Stage Holding

Managing the Melting Transition (327°C)

Holding periods situated near the PTFE melting point of 327°C are vital for preparing the polymer matrix for flow.

This stage stabilizes the material temperature just as it begins its phase transition. It ensures that the entire cross-section of the part enters the melt phase simultaneously, rather than sequentially.

The Sintering Peak (375°C)

The final holding stage at the sintering temperature of 375°C is where the actual composite integration occurs.

At this temperature, the PTFE matrix becomes sufficiently viscous to flow and fully encapsulate the mineral fillers. This creates the physical bond between the polymer and the reinforcement, which is strictly necessary for the composite's mechanical strength.

Achieving Optimal Material Properties

Encouraging Orderly Crystallization

The "significance" of the curve extends beyond simple melting; it dictates the arrangement of polymer chains upon cooling.

A controlled, multi-stage process facilitates orderly crystallization. This organization of the molecular structure is directly responsible for the material's final hardness and chemical resistance.

Densification of the Microstructure

Pressureless sintering relies entirely on thermal energy and time to remove voids.

The correct holding times allow the material to settle into a dense microscopic structure. This high density maximizes the benefits of the mineral reinforcement, resulting in a superior composite.

Understanding the Trade-offs

Process Time vs. Throughput

The primary trade-off in pressureless sintering is the significant time investment required for a quality result.

Adhering to a 1°C per minute ramp rate and multiple holding stages results in long cycle times, which reduces furnace throughput. However, attempting to accelerate this process almost invariably leads to rejected parts due to stress cracking or incomplete filler wetting.

Making the Right Choice for Your Goal

To maximize the performance of your PTFE composites, you must prioritize the heating profile over speed.

- If your primary focus is preventing cracks: strictly adhere to the slow heating rate of 1°C per minute to fully relieve internal stresses before the melt phase.

- If your primary focus is mechanical strength: ensure the holding period at 375°C is long enough for the PTFE to completely flow and encapsulate every mineral filler particle.

Mastering these thermal plateaus is the difference between a brittle part and a robust, industrial-grade composite.

Summary Table:

| Process Stage | Target Temp | Primary Function |

|---|---|---|

| Slow Heating Ramp | Ambient to 327°C | Eliminates residual stresses; prevents thermal gradients and cracking. |

| Melting Transition | ~327°C | Stabilizes material for phase transition; ensures uniform melting. |

| Sintering Peak | ~375°C | Maximizes PTFE flow to fully encapsulate mineral fillers for strength. |

| Controlled Cooling | Post-375°C | Facilitates orderly crystallization for chemical resistance and hardness. |

Optimize Your Sintering Precision with KINTEK

Don't let thermal stress compromise your material integrity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of PTFE composite production. Our lab high-temp furnaces provide the precise temperature control and programmable curves needed to ensure dense, crack-free results every time.

Ready to elevate your material properties? Our systems are fully customizable to meet your unique sintering requirements.

Visual Guide

References

- Chen Wang, Zhimin Bai. Preparation and Tribological Behaviors of Antigorite and Wollastonite Mineral Dual-Phase-Reinforced Polytetrafluoroethylene Matrix Composites. DOI: 10.3390/lubricants12030074

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the difference between electric furnace and muffle furnace? A Guide to Choosing the Right Heating Solution

- What is the role of a high-temperature calcination furnace in preparing ultra-fine oxide nanopowders? Master Purity

- What makes muffle furnaces particularly useful for sensitive materials? Ensure Precision, Purity & Protection

- What are the main applications of a box muffle furnace in material research? Unlock Precision Heat Treatment and Analysis

- How does a laboratory muffle furnace contribute to the electrical polarization of PVDF sensors? Optimize Activation

- In which industries is the muffle furnace commonly used? Essential for Materials Science and Quality Control

- What is the primary function of a laboratory resistance furnace in Al-Li alloy prep? Achieve Optimal Smelting Quality

- What critical role does a high-temperature sintering furnace play in the treatment of Zinc Oxide pellets? Expert Insights