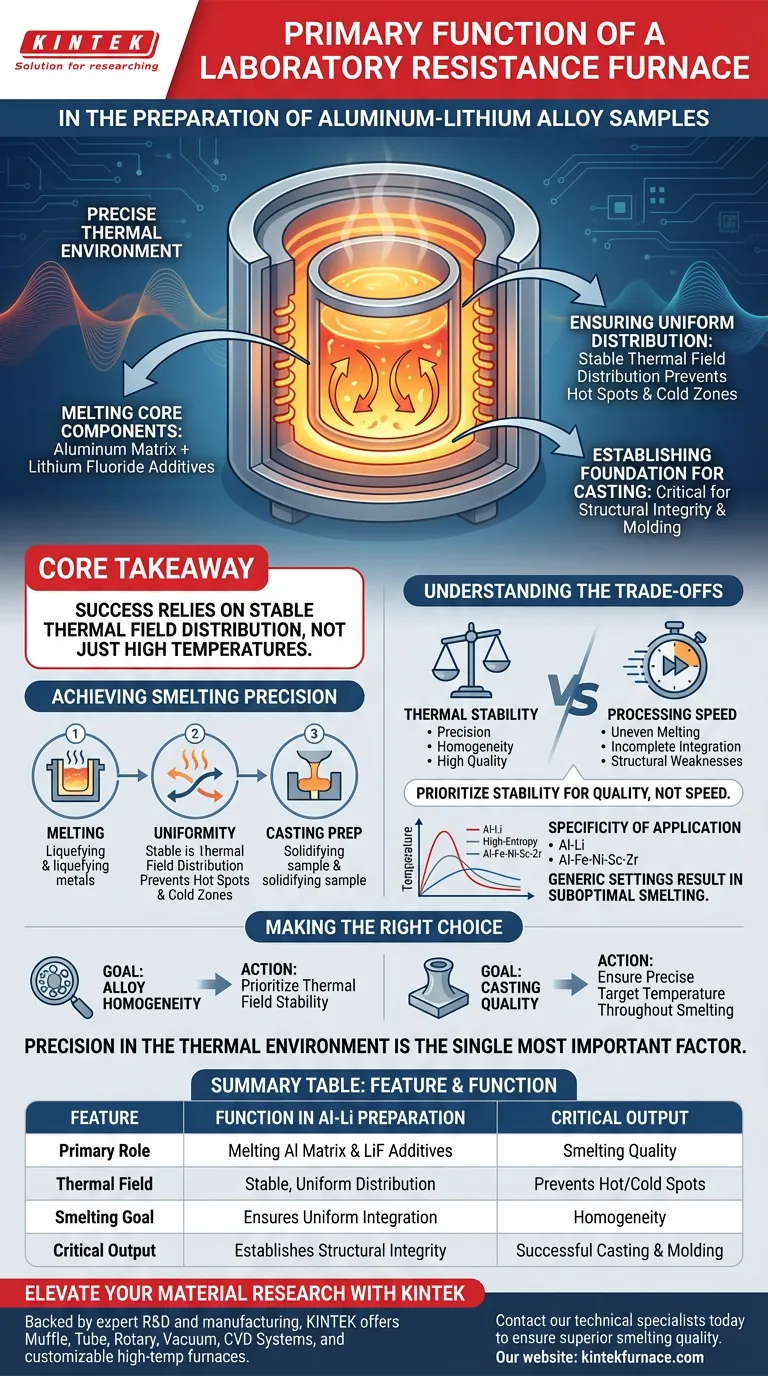

In the preparation of aluminum-lithium alloy samples, the primary function of a laboratory resistance furnace is to provide a precise thermal environment used to melt the aluminum matrix and lithium fluoride additives. By generating a highly stable thermal field, the furnace ensures these components mix uniformly, which is critical for maintaining smelting quality during the foundational casting and molding processes.

Core Takeaway Success in developing aluminum-lithium alloys relies not just on reaching high temperatures, but on achieving a stable thermal field distribution. The resistance furnace facilitates the uniform integration of additives into the matrix, establishing the structural integrity required for subsequent casting.

Achieving Smelting Precision

Melting the Core Components

The fundamental role of the resistance furnace in this specific application is to act as a controlled melting chamber.

It must generate sufficient heat to liquefy the aluminum matrix while simultaneously melting the lithium fluoride additives.

This simultaneous melting is the first critical step in synthesizing the alloy for research and development.

Ensuring Uniform Distribution

Merely melting the materials is insufficient for high-quality alloy production; the internal environment must be consistent.

The furnace provides a stable thermal field distribution, which prevents hot spots or cold zones within the melt.

This thermal stability is the mechanism that ensures the uniform mixing of the aluminum and lithium components throughout the sample.

establishing Foundation for Casting

The quality of the final molded sample is determined during this heating phase.

By maintaining strict control over the smelting quality, the resistance furnace prepares the material for the casting and molding process.

If the thermal environment during this stage is imprecise, the structural properties of the cast sample will be compromised.

Understanding the Trade-offs

Thermal Stability vs. Processing Speed

A resistance furnace is designed for precision and stability, not necessarily for rapid heating cycles.

Prioritizing speed over the stability of the thermal field can lead to uneven melting or incomplete integration of the lithium fluoride additives.

This lack of uniformity introduces structural weaknesses that cannot be corrected in later processing stages.

Specificity of Application

While versatile, the furnace parameters used for aluminum-lithium alloys are specific to that material's melting points and reactivity.

As seen in other alloy applications (such as high-entropy alloys or Al-Fe-Ni-Sc-Zr), different materials require vastly different temperature holding times and targets to achieve results like stress relief or full phase integration.

Applying generic settings without adjusting for the aluminum-lithium matrix requirements will result in suboptimal smelting quality.

Making the Right Choice for Your Goal

To maximize the effectiveness of your laboratory resistance furnace, align your operational parameters with your specific material objectives.

- If your primary focus is Alloy Homogeneity: Prioritize the stability of the thermal field to ensure the lithium fluoride additives mix perfectly with the aluminum matrix.

- If your primary focus is Casting Quality: Ensure the furnace maintains a precise target temperature throughout the smelting duration to prevent defects during the molding phase.

Precision in the thermal environment is the single most important factor in transforming raw materials into a viable aluminum-lithium alloy.

Summary Table:

| Feature | Function in Al-Li Alloy Preparation |

|---|---|

| Primary Role | Melting the aluminum matrix and lithium fluoride additives |

| Thermal Field | Provides a stable, uniform distribution to prevent hot/cold spots |

| Smelting Goal | Ensures uniform integration of additives into the matrix |

| Critical Output | Establishes structural integrity for subsequent casting and molding |

Elevate Your Material Research with KINTEK

Precision in the thermal environment is the defining factor in high-performance alloy synthesis. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet the unique requirements of your aluminum-lithium research.

Don't compromise on alloy homogeneity. Contact our technical specialists today to find the perfect high-temperature solution for your lab and ensure superior smelting quality in every sample.

Visual Guide

References

- Tursunbaev Sarvar, Mardonova Mashhura. DEVELOPMENT OF A MATHEMATICAL MODEL OF THE EFFECT OF LITHIUM ON THE WEAR RESISTANCE PROPERTIES OF ALUMINUM-LITHIUM ALLOYS. DOI: 10.37547/ajast/volume04issue01-07

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of the muffle furnace calcination process at 500 °C? Optimize Your Catalyst Active Sites

- What are the roles of a Muffle furnace and a UV spectrophotometer in determining the lignin content of wood?

- What is the specific application of a muffle furnace in biochar characterization experiments? Optimize Ash Analysis

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What are the energy efficiency considerations for muffle furnaces? Cut Costs with Smart Design

- What role does a laboratory muffle furnace play in the determination of phosphorus content? Essential Dry Ashing Guide

- What role does a muffle furnace play in the post-treatment of Fe2O3 photoanodes? Optimize Hematite Phase Transformation

- How is a box muffle furnace used in chemical experiments? Unlock Precise High-Temperature Processing