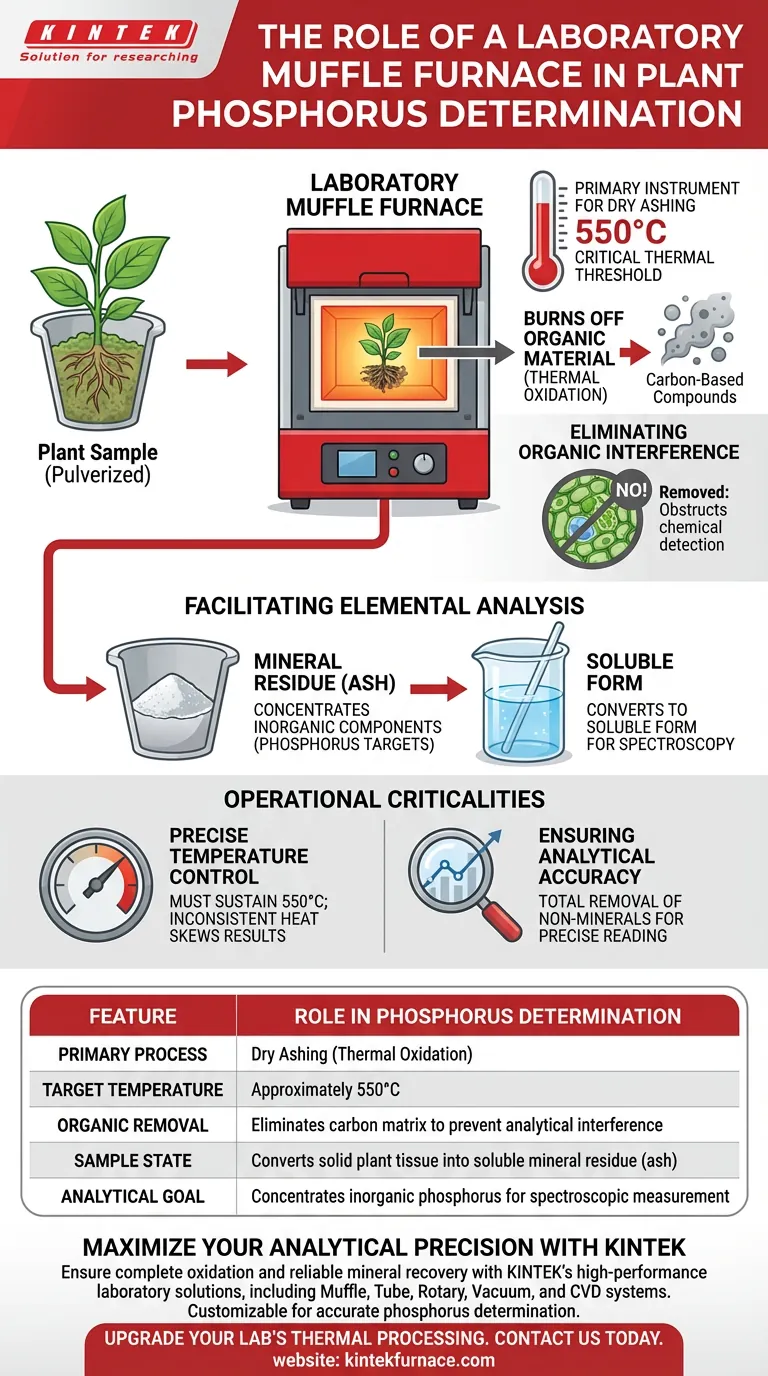

The laboratory muffle furnace acts as the primary instrument for dry ashing. Its function is to heat pulverized plant samples to approximately 550°C, a critical thermal threshold that burns off organic material. This process isolates the mineral content, allowing for the accurate chemical determination of phosphorus.

The muffle furnace effectively eliminates the organic matrix of the plant tissue through controlled high heat. This creates a clean, soluble mineral residue that is essential for precise spectroscopic analysis.

The Mechanics of Dry Ashing

Thermal Oxidation at 550°C

The furnace operates by maintaining a rigorous temperature of approximately 550°C.

At this temperature, the furnace facilitates the complete oxidation of the sample. This intense thermal environment is necessary to break down the complex cellular structures of plant tissue.

Eliminating Organic Interference

The primary objective of this heating cycle is the removal of organic matter.

Plant tissues are largely composed of carbon-based organic compounds. These compounds must be fully eliminated because they obstruct the chemical processes used to detect phosphorus.

Facilitating Elemental Analysis

Creating the Mineral Residue

Once the organic matter is oxidized, the furnace leaves behind a mineral residue (ash).

This residue represents the inorganic components of the plant, including the phosphorus targets. It concentrates the element of interest by removing the bulk of the sample's mass.

Converting to a Soluble Form

The thermal processing converts the solid plant sample into a soluble form.

Solubility is the technical prerequisite for the next step: measurement via spectroscopy. Without the furnace transforming the sample into ash, the phosphorus could not be dissolved and analyzed accurately.

Operational Criticalities

The Necessity of Precise Control

Success depends entirely on precise temperature control.

The furnace must sustain the target temperature without significant fluctuation. Inconsistent heat can lead to incomplete oxidation, leaving behind organic carbon that skews the final results.

Ensuring Analytical Accuracy

The muffle furnace is not just a heating element; it is an accuracy tool.

By ensuring the total removal of non-mineral components, it guarantees that the spectroscopic reading reflects only the phosphorus content, not background noise from the plant tissue.

Ensuring Process Integrity

To maximize the reliability of your phosphorus determination, consider these distinct goals:

- If your primary focus is Preparation Quality: Ensure the plant samples are thoroughly pulverized before placing them in the furnace to guarantee uniform oxidation.

- If your primary focus is Analytical Precision: Verify that the furnace is calibrated to hold exactly 550°C to ensure the complete conversion of organic solids to soluble minerals.

The muffle furnace provides the essential bridge between raw biological samples and quantifiable chemical data.

Summary Table:

| Feature | Role in Phosphorus Determination |

|---|---|

| Primary Process | Dry Ashing (Thermal Oxidation) |

| Target Temperature | Approximately 550°C |

| Organic Removal | Eliminates carbon matrix to prevent analytical interference |

| Sample State | Converts solid plant tissue into soluble mineral residue (ash) |

| Analytical Goal | Concentrates inorganic phosphorus for spectroscopic measurement |

Maximize Your Analytical Precision with KINTEK

Ensure complete oxidation and reliable mineral recovery with KINTEK’s high-performance laboratory solutions. Backed by expert R&D and precision manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of elemental analysis. Our lab high-temp furnaces are fully customizable to meet your unique research needs, providing the stable temperature control essential for accurate phosphorus determination.

Ready to upgrade your lab's thermal processing? Contact us today to discuss how our specialized equipment can enhance your sample preparation quality.

Visual Guide

References

- Andressa Nakagawa, Papa Saliou Sarr. Calcined low-grade phosphate rock fertilization enhances nitrogen fixation, yield, and grain quality in soybeans. DOI: 10.3389/fpls.2025.1581961

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a high-temperature muffle furnace required for the roasting of activated fly ash? Unlock Efficient Phase Changes

- What are the construction features and temperature capabilities of a muffle furnace? Key Insights for Your Lab

- What role do box type resistance furnaces play in semiconductor processes? Essential for Thermal Oxidation and Annealing

- What is a muffle furnace and how does it differ from a vacuum furnace? Choose the Right High-Temperature Solution

- How do muffle furnaces contribute to drug testing in pharmaceuticals? Ensure Purity and Compliance with Precision

- Why is the thermal sintering process in a muffle furnace necessary for post-processing aluminum matrix composites?

- What role does a high-temperature laboratory oven play in catalyst activation? Boost Surface Area and Performance

- What role does a Box Furnace play during the oxidative stabilization of nanofibers? Essential Chemical Transformation