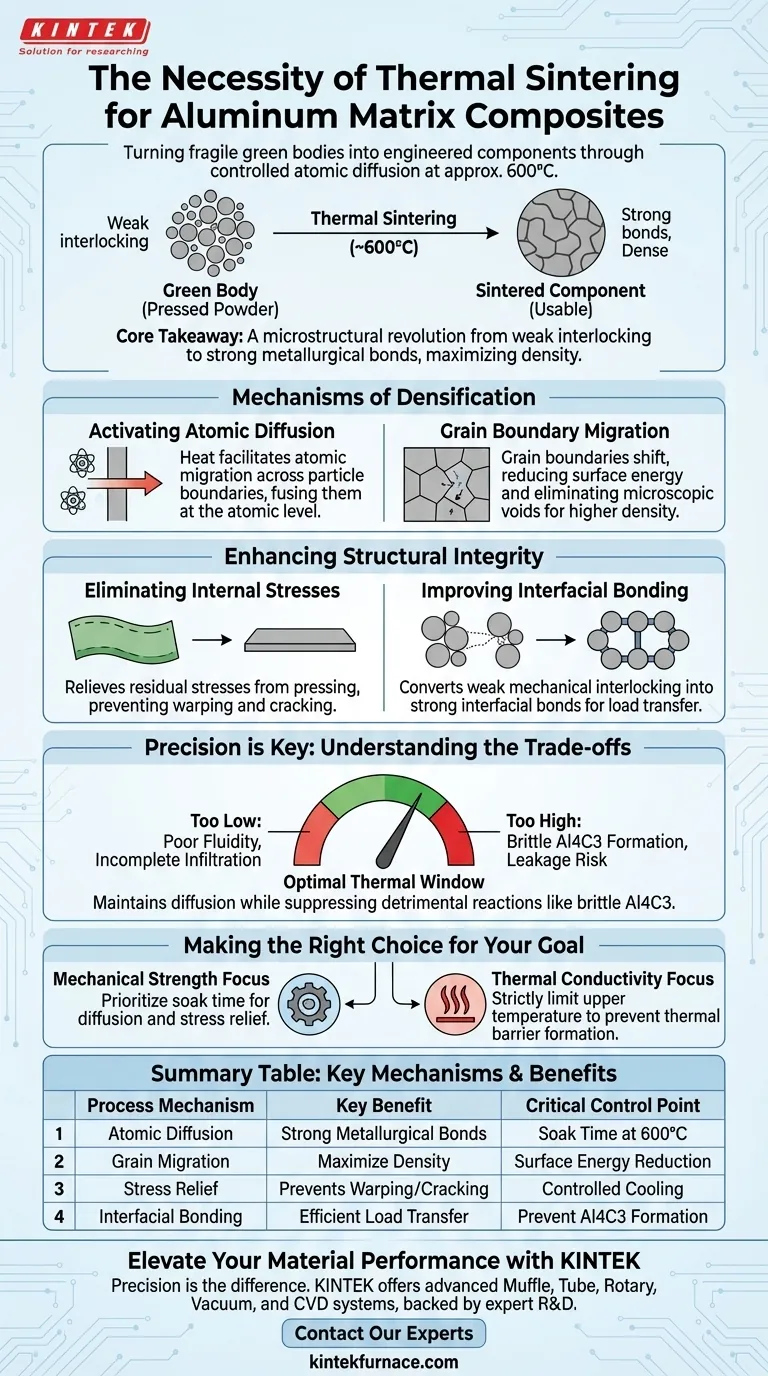

Thermal sintering in a muffle furnace is the critical transformation step that turns a fragile, pressed powder mixture into a usable engineering component. By exposing the "green body" (the pressed powder) to a controlled environment of approximately 600°C, the furnace activates atomic diffusion, allowing the aluminum matrix to bond physically and chemically without melting completely.

Core Takeaway Sintering is not merely a drying process; it is a microstructural revolution. It drives atomic diffusion and grain boundary migration to replace weak mechanical interlocking with strong metallurgical bonds, effectively eliminating internal stresses and maximizing the density of the final composite.

The Mechanisms of Densification

Activating Atomic Diffusion

The primary function of the muffle furnace is to facilitate atomic movement. At elevated temperatures (such as the 600°C benchmark), atoms gain enough thermal energy to migrate across particle boundaries.

This diffusion bridges the gaps between individual powder particles. It fuses them together at the atomic level, creating a continuous solid network from what was previously a loose collection of granules.

Grain Boundary Migration

As diffusion progresses, the boundaries between grains begin to shift and migrate. This migration reduces the total surface energy of the material, driving the microstructure toward a more stable state.

This process is essential for eliminating the microscopic voids inherent in pressed powders. The result is a significantly denser material with superior mechanical integrity.

Enhancing Structural Integrity

Eliminating Internal Stresses

The initial "green body" created by pressing powder is full of residual internal stresses. Without thermal treatment, these stresses can lead to warping or cracking under load.

The heat provided by the muffle furnace acts as a stress-relief mechanism. It allows the material lattice to relax, ensuring the final component is dimensionally stable and less prone to premature failure.

Improving Interfacial Bonding

Mechanical pressing alone only provides weak interlocking between the aluminum matrix and reinforcement particles. Thermal sintering converts these weak contacts into strong interfacial bonds.

This enhanced bonding force is what gives the composite its final strength. It ensures that mechanical loads are effectively transferred from the softer aluminum matrix to the stronger reinforcement material.

Understanding the Trade-offs: Precision is Key

The Risk of Overheating

While high heat is necessary for diffusion, precise temperature control is non-negotiable. If the temperature exceeds the optimal window, it can trigger severe interfacial reactions.

Specifically, excessive heat can generate brittle aluminum carbide (Al4C3). This compound compromises the material's thermal conductivity and introduces brittleness, negating the benefits of the composite.

The Fluidity Balance

Temperature control also dictates the fluidity of the aluminum matrix. If the temperature is too low, the aluminum will exhibit poor fluidity, leading to incomplete infiltration and weak bonding.

Conversely, if the temperature is too high, the matrix may become too fluid. This can lead to the leakage of molten aluminum from the compact, resulting in dimensional inaccuracies and material loss.

Making the Right Choice for Your Goal

To maximize the effectiveness of the muffle furnace sintering process, align your parameters with your specific performance objectives:

- If your primary focus is Mechanical Strength: Prioritize a soak time (e.g., 2 hours) that maximizes atomic diffusion and stress relief without pushing temperatures into the range where brittle carbides form.

- If your primary focus is Thermal Conductivity: strictly limit the upper temperature bounds to prevent the formation of Al4C3, as even small amounts of this interface reaction can act as a thermal barrier.

Success in sintering relies not just on applying heat, but on maintaining the precise thermal window where diffusion is active but detrimental chemical reactions are suppressed.

Summary Table:

| Process Mechanism | Key Benefit | Critical Control Point |

|---|---|---|

| Atomic Diffusion | Converts mechanical interlocking into strong metallurgical bonds | Soak time at 600°C |

| Grain Migration | Eliminates microscopic voids to maximize material density | Surface energy reduction |

| Stress Relief | Prevents warping and cracking in the final component | Controlled cooling phases |

| Interfacial Bonding | Ensures efficient load transfer between matrix and reinforcement | Preventing Al4C3 formation |

Elevate Your Material Performance with KINTEK

Precision is the difference between a high-performance composite and a brittle failure. KINTEK provides the advanced thermal solutions necessary to master atomic diffusion and grain boundary migration. Backed by expert R&D and manufacturing, we offer high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique lab requirements.

Don't let suboptimal thermal windows compromise your research. Contact our experts today to find the perfect sintering solution for your aluminum matrix composites and ensure superior structural integrity every time.

Visual Guide

References

- Salih Y. Darweesh, Ghazi F. Mahal. Effect of Adding Nano Silica on Some Structural and Thermal Properties of Aluminum. DOI: 10.55810/2313-0083.1094

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a vacuum furnace differ from a muffle furnace in terms of operation? Choose the Right Furnace for Your Lab

- What are the main applications of a box muffle furnace in material research? Unlock Precision Heat Treatment and Analysis

- How does a muffle furnace contribute to energy efficiency? Achieve Cost Savings and Precise Heating

- What are the advantages of using microwave-assisted heating for PdPc:SnZnO? Boost Structural Integrity and Speed

- What process conditions must a muffle furnace satisfy for CoNiCrAlY oxidation? Ensure Precise High-Temp Stability

- What function does a high-temperature muffle furnace serve for Ni/Co catalysts? Transform Salts into Active Metal Oxides

- How does a muffle furnace differ from a conventional oven? Key Differences for High-Temperature Precision

- Why is an industrial-grade muffle furnace required for kaolin calcination? Ensure Precise Structural Transformation