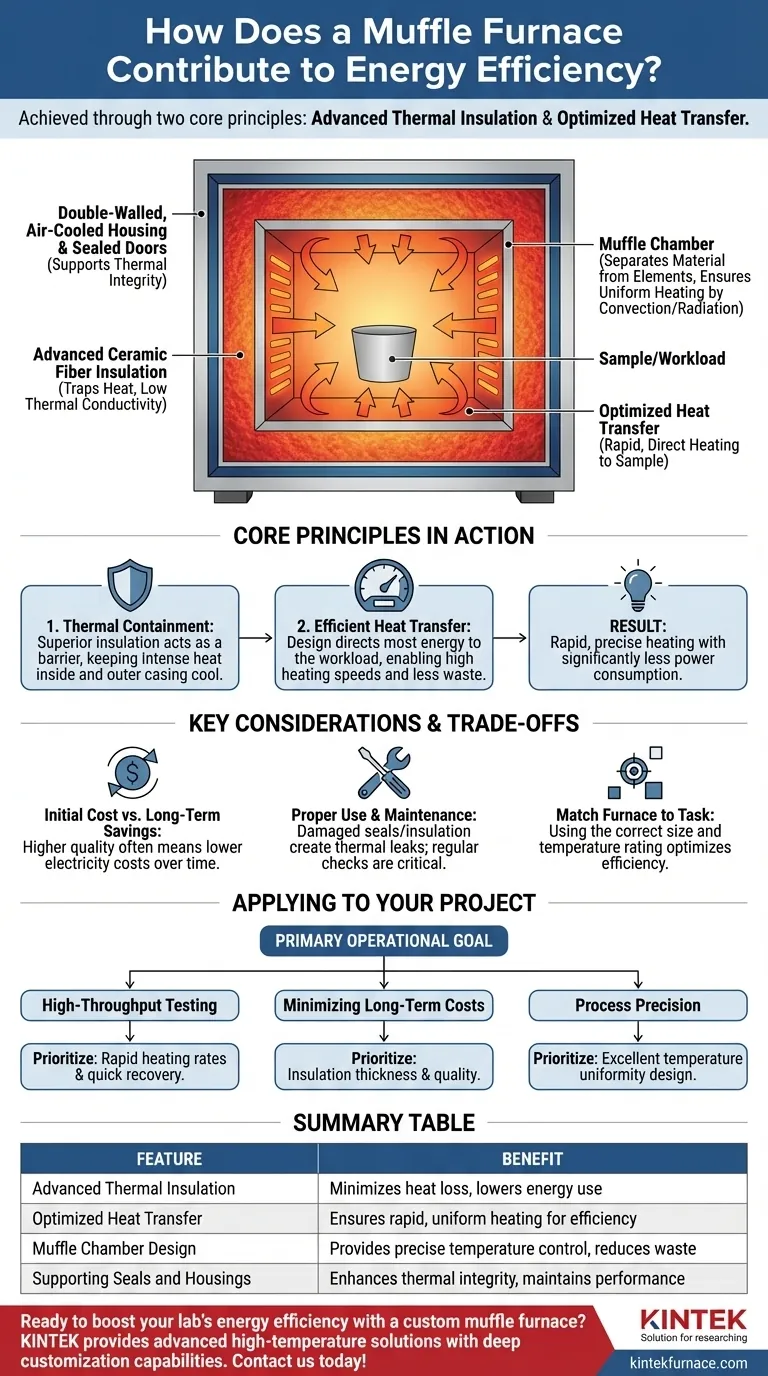

At its core, a muffle furnace achieves energy efficiency through two fundamental principles working in tandem. It uses advanced thermal insulation to trap heat within the chamber, preventing energy loss to the surrounding environment, and its design ensures that the generated heat is transferred rapidly and uniformly to the workload.

The challenge of any high-temperature process is reaching and maintaining a stable temperature without exorbitant energy consumption. A muffle furnace addresses this by creating a highly contained thermal system where minimal energy is wasted, allowing for rapid, precise heating with significantly less power than older or less sophisticated designs.

The Anatomy of an Efficient Muffle Furnace

To understand its efficiency, you must look at how the furnace is constructed as a complete system. Each component is engineered to either retain or effectively direct heat.

The Principle of Thermal Containment

The primary source of energy efficiency is superior insulation. The furnace chamber is lined with thick, lightweight, fireproof ceramic fiber insulation.

This material has extremely low thermal conductivity, meaning it is very poor at transferring heat. This acts as a thermal barrier, keeping the intense heat inside the chamber and the outer casing cool to the touch.

Optimizing Heat Transfer to the Chamber

While insulation prevents heat from escaping outward, it is also designed to efficiently reflect and transfer heat inward.

The heating elements are positioned around the "muffle" or chamber. The insulation ensures that the vast majority of the energy radiated by these elements is directed into the chamber and absorbed by the sample, not lost into the furnace walls.

This efficient internal transfer is why muffle furnaces have high heating speeds, reaching their target temperature quickly and saving energy during heat-up cycles.

The Role of the Muffle Itself

The term "muffle" refers to the chamber that separates the material being heated from the direct radiation and combustion byproducts of the heating elements.

This separation ensures the sample is heated uniformly by convection and radiation within the chamber, not by direct, uneven exposure to the elements. This provides precise thermal control, which is a form of process efficiency, preventing ruined samples and wasted runs.

Supporting Design Features

Efficiency is further enhanced by design details like double-walled, air-cooled housings and tightly sealed, insulated doors. These features minimize any remaining avenues for heat to escape, contributing to the overall thermal integrity of the system.

Understanding the Trade-offs and Considerations

While highly efficient, a muffle furnace is a specialized piece of equipment. Understanding its limitations is key to making an informed decision.

Initial Cost vs. Operational Savings

Modern, efficient muffle furnaces often have a higher upfront purchase price due to the quality of the insulation, digital controls, and overall construction.

However, this initial investment is typically offset over the furnace's lifespan by significant savings in electricity costs, especially in environments where the furnace is used frequently.

The Importance of Proper Use

A furnace's efficiency is directly tied to its condition. A damaged door seal or cracked internal insulation will create a major thermal leak, drastically increasing energy consumption and compromising temperature stability.

Regular inspection and proper maintenance are critical to preserving the energy-efficient performance you invested in.

Matching the Furnace to the Task

Efficiency is relative to the application. Using a large furnace for a very small sample is inherently inefficient, as you are paying to heat a large, empty volume.

Similarly, selecting a furnace with a temperature rating far exceeding your needs can be less efficient than choosing one optimized for your specific temperature range.

How to Apply This to Your Project

Your choice should be guided by your primary operational goal.

- If your primary focus is high-throughput testing: Prioritize a model with documented rapid heating rates and quick temperature recovery, which are direct results of efficient heat transfer.

- If your primary focus is minimizing long-term operational costs: Scrutinize the specifications for insulation thickness and quality, as this is the single biggest factor in reducing sustained energy use.

- If your primary focus is process precision: Select a furnace where the muffle design is explicitly stated to provide excellent temperature uniformity, ensuring repeatable and accurate results.

By understanding how these design principles translate into performance, you can select a furnace that meets both your technical requirements and your operational budget.

Summary Table:

| Feature | Benefit |

|---|---|

| Advanced Thermal Insulation | Minimizes heat loss, lowers energy use |

| Optimized Heat Transfer | Ensures rapid, uniform heating for efficiency |

| Muffle Chamber Design | Provides precise temperature control, reduces waste |

| Supporting Seals and Housings | Enhances thermal integrity, maintains performance |

Ready to boost your lab's energy efficiency with a custom muffle furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can help you save energy and achieve superior results!

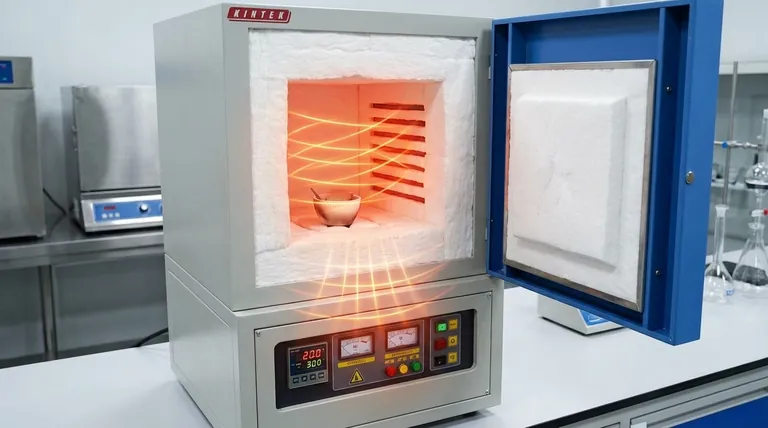

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination