The fundamental difference between a vacuum furnace and a muffle furnace lies in the environment where heating occurs. A vacuum furnace operates by first removing air and other gases to create a vacuum, thereby preventing atmospheric contamination. In contrast, a muffle furnace heats material within a standard or controlled atmosphere, using a physical chamber (the "muffle") to shield the workload from direct contact with the heating elements.

Your choice between these two furnaces is not about which is superior, but which atmospheric environment your process requires. The decision ultimately hinges on your material's sensitivity to oxidation and other atmospheric reactions during heating.

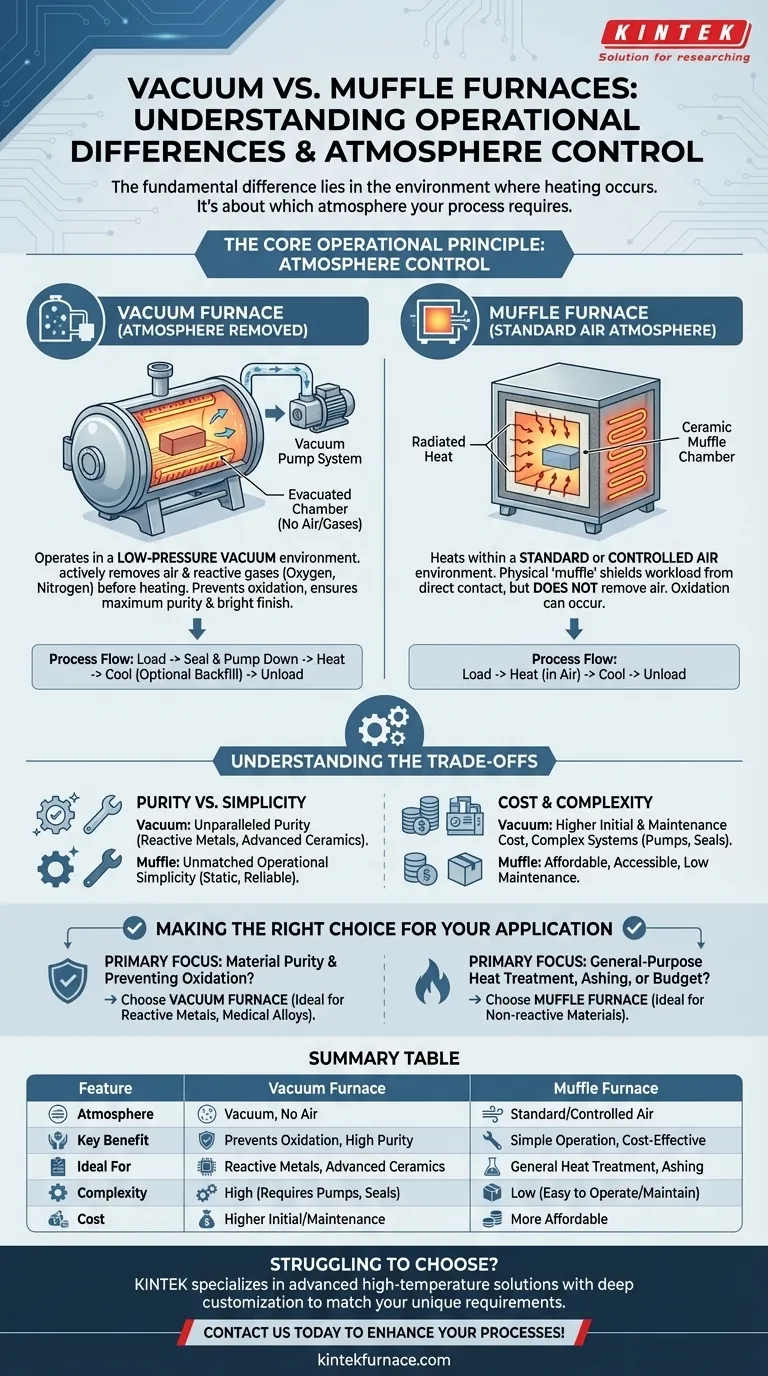

The Core Operational Principle: Atmosphere Control

The most critical distinction is how each furnace manages the atmosphere surrounding the material being processed. This single factor dictates their ideal applications.

How a Vacuum Furnace Operates

A vacuum furnace is a sealed chamber connected to a pumping system. Before the heating cycle begins, these pumps actively remove the air and moisture from the chamber, creating a low-pressure, or vacuum, environment.

This process eliminates reactive gases like oxygen and nitrogen. Heating in a vacuum prevents oxidation and other unwanted chemical reactions on the material's surface, ensuring maximum purity and a bright, clean finish.

How a Muffle Furnace Operates

A muffle furnace contains an inner chamber, or muffle, typically made of ceramic. The furnace's heating elements heat the outside of this muffle.

The muffle then radiates heat inward, evenly heating the material placed inside it. This design isolates the material from direct radiation or flame impingement but does not remove the air from within the muffle. The process occurs in a standard air atmosphere.

Understanding the Trade-offs

Each design comes with a distinct set of advantages and limitations that make them suitable for different tasks and budgets.

Purity vs. Simplicity

A vacuum furnace provides an unparalleled level of purity, essential for processing reactive metals, advanced ceramics, and medical-grade alloys where any surface oxidation is unacceptable.

A muffle furnace, while unable to prevent atmospheric reactions, offers unmatched operational simplicity. It is a static, box-shaped instrument where the workload remains fixed for the entire cycle, making it easy to operate and maintain.

Cost and Complexity

The simplicity of a muffle furnace makes it a generally affordable and accessible piece of equipment for many labs and workshops. Its straightforward design requires less specialized maintenance.

Vacuum furnaces are inherently more complex systems. They require vacuum pumps, seals, and precise controls to manage the environment, which significantly increases their initial cost and the complexity of operation and maintenance.

Process Flow

Operating a muffle furnace is a direct process: load the material, close the door, run the heating program, and unload after cooling.

Operating a vacuum furnace involves additional critical steps: loading the material, sealing the chamber, pumping the chamber down to the required vacuum level, running the heating program, and often backfilling with an inert gas to assist in cooling before unloading.

Making the Right Choice for Your Application

Your decision depends entirely on your material's requirements and your operational constraints.

- If your primary focus is material purity and preventing oxidation: A vacuum furnace is the correct choice, as it is specifically designed to eliminate the reactive atmosphere that causes contamination.

- If your primary focus is general-purpose heat treatment, ashing, or processing non-reactive materials on a budget: A muffle furnace provides a simple, reliable, and cost-effective solution.

By understanding that atmosphere control is the defining factor, you can confidently select the furnace that aligns perfectly with your technical goals and budget.

Summary Table:

| Feature | Vacuum Furnace | Muffle Furnace |

|---|---|---|

| Atmosphere | Vacuum environment, no air or gases | Standard or controlled air atmosphere |

| Key Benefit | Prevents oxidation, ensures high purity | Simple operation, cost-effective |

| Ideal For | Reactive metals, advanced ceramics, medical alloys | General heat treatment, ashing, non-reactive materials |

| Complexity | High (requires pumps, seals) | Low (easy to operate and maintain) |

| Cost | Higher initial and maintenance costs | More affordable and accessible |

Struggling to choose the right furnace for your lab's needs? KINTEK specializes in advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our exceptional R&D and in-house manufacturing, we offer deep customization to precisely match your unique experimental requirements, ensuring optimal performance and purity. Contact us today to discuss how our furnaces can enhance your processes and drive innovation in your laboratory!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What technological features enhance the efficiency of vacuum furnaces? Boost Performance with Advanced Control & Energy Savings

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy