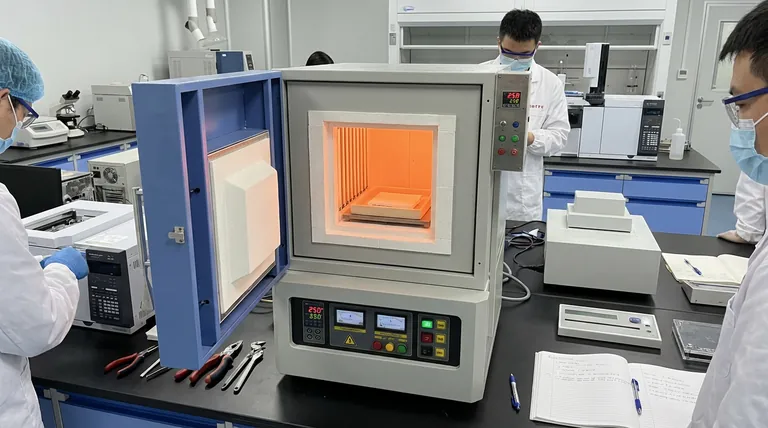

The Box Furnace serves as the critical reaction chamber for the oxidative stabilization of electrospun nanofibers. It exposes Polyacrylonitrile (PAN) fibers to a controlled air environment—typically heating them to approximately 250°C—to trigger essential chemical changes. This thermal treatment is the specific mechanism that converts the fiber from a meltable plastic into a heat-resistant structure capable of surviving higher temperatures.

The central purpose of the Box Furnace is to fundamentally alter the fiber's chemistry before carbonization. By facilitating specific reactions in an air atmosphere, it transforms the polymer from a thermoplastic state (which would melt) into a thermoset ladder structure (which retains its shape), ensuring the nanofiber's physical morphology remains intact.

The Chemical Transformation Process

Creating a Heat-Resistant Ladder Structure

The primary reference highlights that the Box Furnace does not merely dry the fibers; it restructures them.

The heat treatment converts the initial thermoplastic linear polymer into a heat-resistant ladder structure. This structural change is what allows the fiber to endure future processing without degrading.

Driving Key Chemical Reactions

Inside the furnace, the combination of heat and air facilitates three specific reactions in the PAN material: cyclization, dehydrogenation, and oxidation.

These reactions act in concert to stabilize the molecular chains. This chemical evolution is necessary to lock the fiber's atomic structure in place.

The Necessity of an Air Environment

Unlike subsequent steps that may require inert atmospheres, the Box Furnace operates specifically in an air environment.

Oxygen is a required reactant for the oxidative stabilization process. The furnace provides the controlled atmospheric conditions needed for oxygen to interact with the polymer chains effectively.

Ensuring Structural Integrity

Converting Thermoplastic to Thermoset

A vital function of the furnace is managing the phase transition of the material.

As noted in the supplementary data, this step transforms the fiber from thermoplastic to thermoset. A thermoplastic material serves as the precursor, but it lacks the thermal stability required for advanced applications.

Preventing Melting and Collapse

Without the stabilization provided by the Box Furnace, the nanofibers would lose their physical definition.

If the fibers were exposed to high-temperature carbonization without this step, they would melt or collapse. The furnace ensures the fibers maintain their "as-spun" morphology throughout the rest of the production line.

Understanding the Trade-offs

Precision vs. Speed

The supplementary references indicate that this process is not instantaneous. It requires a precise temperature-controlled program, often involving very slow heating rates (e.g., 0.2 degrees Celsius per minute).

While this slow ramp rate is critical for proper cross-linking and avoiding thermal shock, it creates a bottleneck in production speed. Rushing this step in the furnace can result in incomplete stabilization, leading to structural failure in later stages.

Making the Right Choice for Your Goal

How to Apply This to Your Project

The Box Furnace is not just a heater; it is a chemical reactor. Your approach to using it should depend on the specific quality metrics of your final fiber.

- If your primary focus is Physical Morphology: Ensure your furnace program allows sufficient time for the thermoplastic to thermoset conversion to prevent the fibers from fusing or collapsing.

- If your primary focus is Chemical Stability: Prioritize the precise control of the air environment and temperature ramp to fully facilitate cyclization and oxidation without burning the material.

The Box Furnace is the definitive gateway that bridges the gap between a raw, fragile polymer and a robust, heat-resistant carbon precursor.

Summary Table:

| Stabilization Phase | Key Chemical Reactions | Temperature Requirement | Atmospheric Condition | Resulting Structure |

|---|---|---|---|---|

| Oxidative Stabilization | Cyclization, Dehydrogenation, Oxidation | Approx. 250°C (Slow Ramp) | Controlled Air (Oxygen) | Thermoset Ladder Structure |

| Morphology Control | Cross-linking | Precise Thermal Program | Constant Airflow | Non-meltable, Intact Fiber |

Elevate Your Nanofiber Research with KINTEK

Precise thermal processing is the difference between a successful carbon fiber and a melted polymer. KINTEK’s high-performance Box Furnaces provide the meticulous temperature ramp control (as low as 0.2°C/min) and atmospheric uniformity required for the critical oxidative stabilization of PAN nanofibers.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your laboratory's unique high-temperature needs. Ensure your materials achieve the perfect thermoset ladder structure with our specialized lab equipment.

Ready to optimize your fiber production? Contact KINTEK today for a custom solution.

References

- Juhyeong Kim, Yoonkook Son. Lotus Root Type Nickel Oxide-Carbon Nanofibers: A Hybrid Supercapacitor Electrode Material. DOI: 10.3390/app14072977

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is a laboratory high-temperature muffle furnace utilized in g-C3N4 synthesis? Optimize Your Thermal Polycondensation

- What physical principles govern muffle furnace operation? Master Energy, Heat Transfer, and Control

- What should be evaluated regarding the heating elements in a muffle furnace? Ensure Optimal Performance and Longevity

- What is the function of a box muffle furnace in air annealing? Master Tin Oxide Catalyst Synthesis

- What is a box type resistance furnace and what is it used for? Discover Precision Heating Solutions

- How do sample characteristics affect muffle furnace selection? Ensure Accurate and Safe High-Temperature Processing

- What are the temperature capabilities of drying ovens compared to muffle furnaces? Choose the Right Tool for Your Lab

- What are the advantages of repeated calcination-reconstruction cycles for CuO nanoparticles? Master Precision Control