When evaluating a muffle furnace, the heating elements are the engine of the entire process. A proper assessment requires you to look beyond the furnace's sticker price or chamber size. You must evaluate the element's type and quality to ensure uniform heat, verify its maximum temperature rating to prevent damage, and understand its supported heating rate to determine process efficiency.

A heating element cannot be judged in isolation. Its true value is revealed by how it integrates with the furnace's control system, safety features, and operational procedures to deliver consistent, reliable, and safe performance for your specific application.

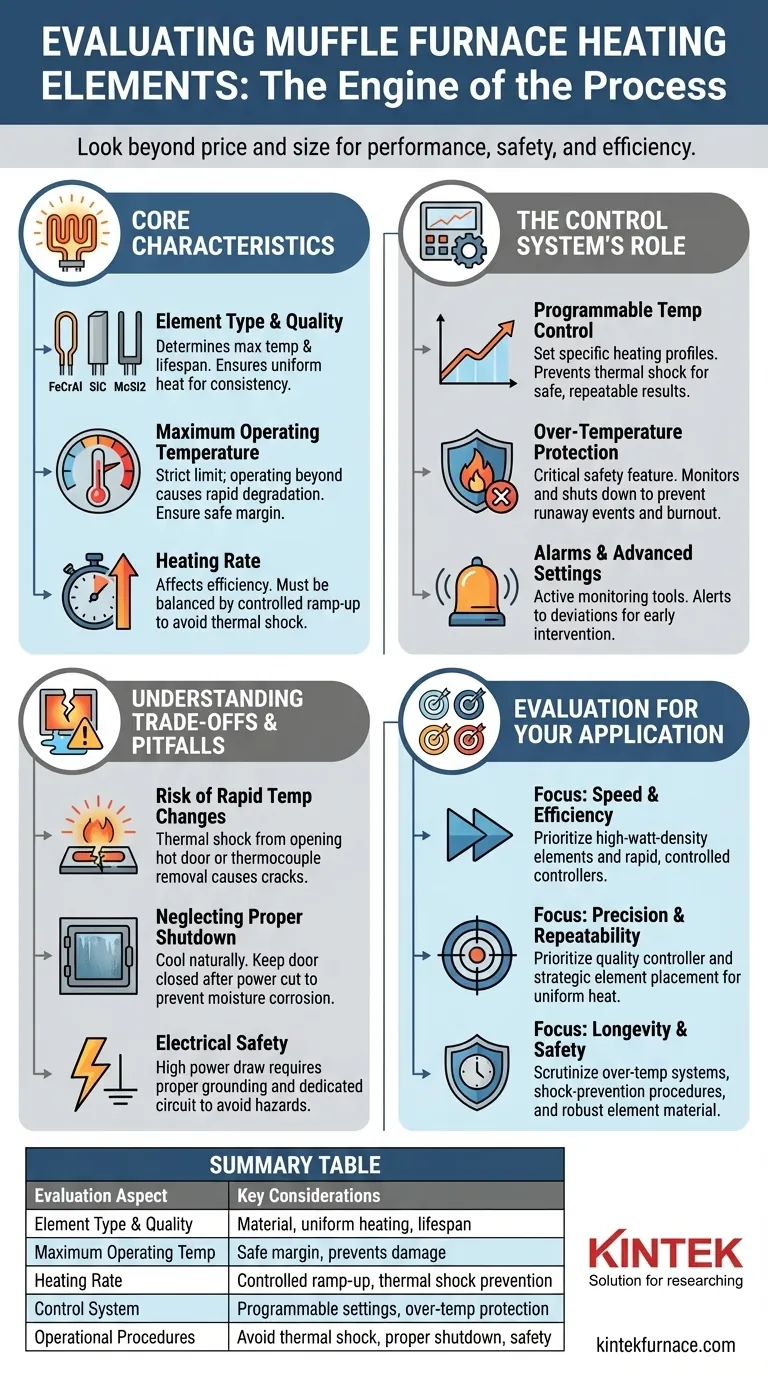

Core Characteristics of the Heating Element

The physical and material properties of the heating elements are the foundation of the furnace's performance. These dictate its temperature range, speed, and suitability for different tasks.

Element Type and Quality

The material of the heating element directly determines its maximum operating temperature and lifespan. Common materials include iron-chromium-aluminum (FeCrAl) alloys for general-purpose use and silicon carbide (SiC) or molybdenum disilicide (MoSi2) for higher temperature applications.

High-quality elements, combined with strategic placement within the chamber, are essential for achieving consistent and uniform heating, which is critical for repeatable results.

Maximum Operating Temperature

Every heating element has a strict maximum temperature limit. Operating the furnace beyond this point will cause rapid degradation and premature failure of the elements, potentially damaging the entire furnace.

Always ensure the furnace's maximum rated temperature provides a safe margin above your required working temperature.

Heating Rate

The heating rate determines how quickly the furnace can reach its target temperature. This is a key factor for process efficiency and throughput.

A furnace's ability to achieve a fast heating rate depends on the power and design of its elements, but this must be balanced by a control system that can manage the temperature increase gradually to avoid thermal shock.

The Control System's Role in Element Health

A powerful heating element is ineffective without a precise control system. The controller acts as the brain, protecting the elements and ensuring accurate process execution.

Programmable Temperature Control

Modern furnaces use programmable controllers to manage the heating process. This software allows you to set specific heating profiles, including gradual voltage increases, to raise the temperature smoothly.

This controlled ramp-up prevents thermal shock, a primary cause of element damage, and ensures the process is both safe and repeatable.

Over-Temperature Protection

A critical safety feature is the furnace's ability to monitor its own temperature and shut down if an issue occurs. This prevents a control system failure from causing a thermal runaway event.

This automatic protection is your primary defense against accidental element burnout and catastrophic furnace damage.

Alarms and Advanced Settings

Sophisticated controllers offer alarms, timers, and other programmable options. These features are not just for convenience; they are active monitoring tools that can alert you to deviations from the set program, allowing for intervention before a minor issue becomes a major failure.

Understanding the Trade-offs and Common Pitfalls

Proper operation is as important as the quality of the components. Many heating element failures are caused by user error or a misunderstanding of the furnace's limitations.

The Risk of Rapid Temperature Changes

Heating elements are brittle, especially at high temperatures. Subjecting them to thermal shock by opening the door to cool the chamber rapidly or removing a hot thermocouple can cause them to crack or break.

Always follow the manufacturer's recommended heating and cooling programs, allowing the furnace to cool down naturally.

Neglecting Proper Shutdown Procedures

After a process is complete, the furnace power must be cut off and the door should remain closed until it has cooled significantly. This protects the furnace chamber and elements from ambient moisture, which can cause corrosion and degradation over time.

Electrical Safety and Grounding

The heating elements draw a significant amount of power. The furnace must be properly grounded to prevent electric shock hazards.

It is crucial to use a dedicated electrical circuit with an appropriate controller or gate to avoid overloading the system.

Making the Right Evaluation for Your Application

Your evaluation of the heating elements should be directly tied to the primary goal of your work.

- If your primary focus is process speed and efficiency: Prioritize furnaces with high-watt-density elements and a sophisticated controller that allows for rapid yet controlled heating rates.

- If your primary focus is precision and repeatability: Focus on the quality of the temperature controller and the strategic placement of the elements to ensure maximum thermal uniformity across the entire chamber.

- If your primary focus is longevity and safety: Scrutinize the over-temperature protection systems, the recommended operational procedures for preventing thermal shock, and the robustness of the element material itself.

By viewing the heating elements as part of an integrated system, you can make a more informed decision that ensures reliable results for years to come.

Summary Table:

| Evaluation Aspect | Key Considerations |

|---|---|

| Element Type and Quality | Material (e.g., FeCrAl, SiC, MoSi2), uniform heating, lifespan |

| Maximum Operating Temperature | Safe margin above working temperature, prevents damage |

| Heating Rate | Controlled ramp-up, efficiency, thermal shock prevention |

| Control System Integration | Programmable settings, over-temperature protection, alarms |

| Operational Procedures | Avoid thermal shock, proper shutdown, electrical safety |

Need a reliable high-temperature furnace solution tailored to your lab's needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental requirements, enhancing efficiency and safety. Contact us today to discuss how we can support your application with durable, high-performance equipment!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?